SV200 R200

4/2007© by GLOBAL GARDEN PRODUCTS

– apply a film of oil on the valve stems before

inserting them in their respective housings;

– ensure the correct position of the inlet valve

and the exhaust valve, marked, respectively,

with «IN» and «EX» on the valve head.

52 Remount the cylinder head [

6.9.C].

53 The valve clearances must be checked whenev-

er the cylinder head is removed and refitted [

6.9.B

].

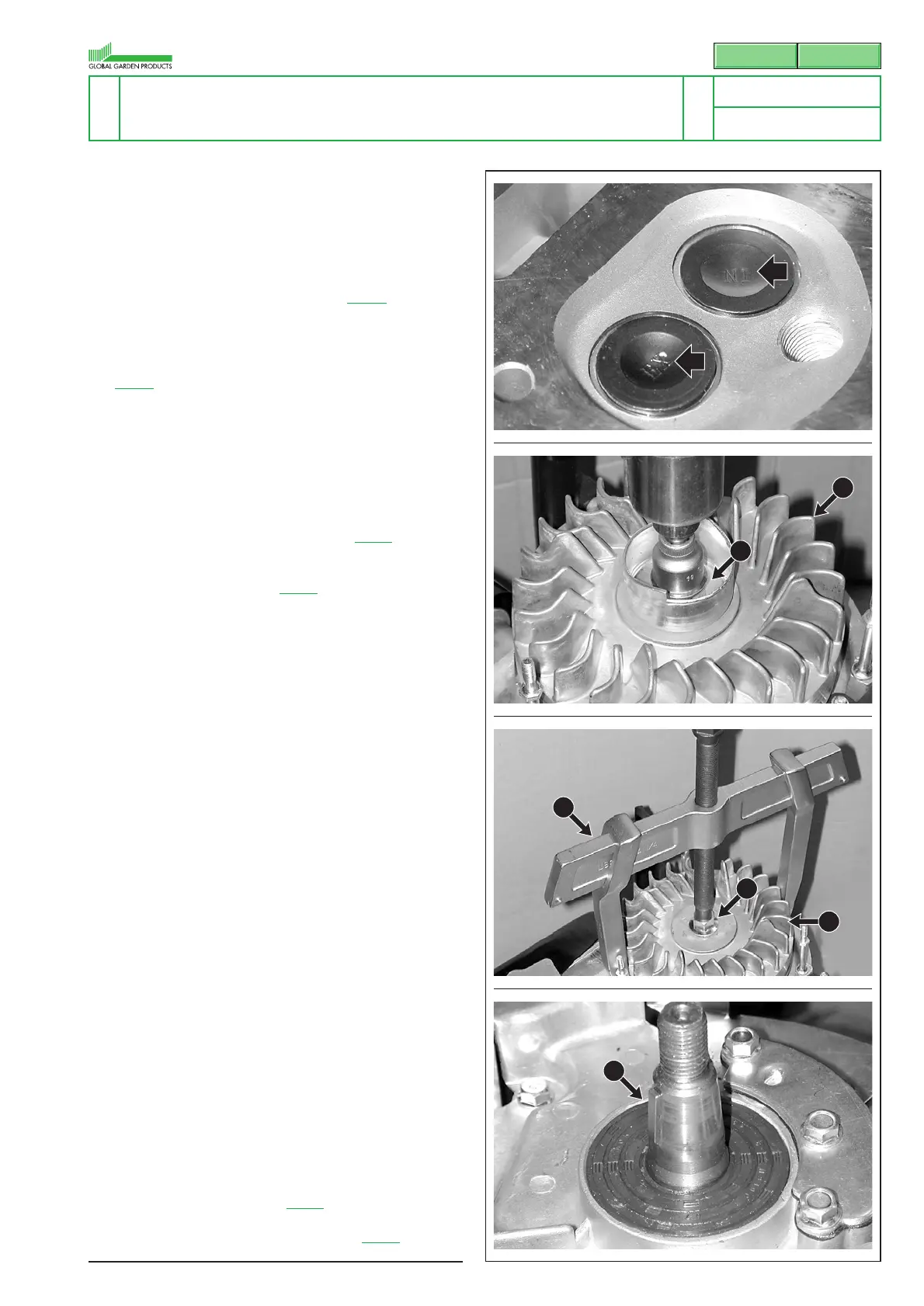

E) Dismantling and replacing the magneto

flywheel

61 Remove the starting system [ 6.2.A].

62 Remove the tank [

6.1.A].

63 Remove the conveyor (20).

NOTE - If no tools are available for locking rota-

tion of the engine shaft, a striker gun must be

used for removing and refitting the flywheel.

64 Use a striker gun to unscrew the nut (41) locking

the magneto flywheel (42).

65 Screw the nut (41) a few turns onto the engine

shaft so that the puller is not working directly on

the shaft.

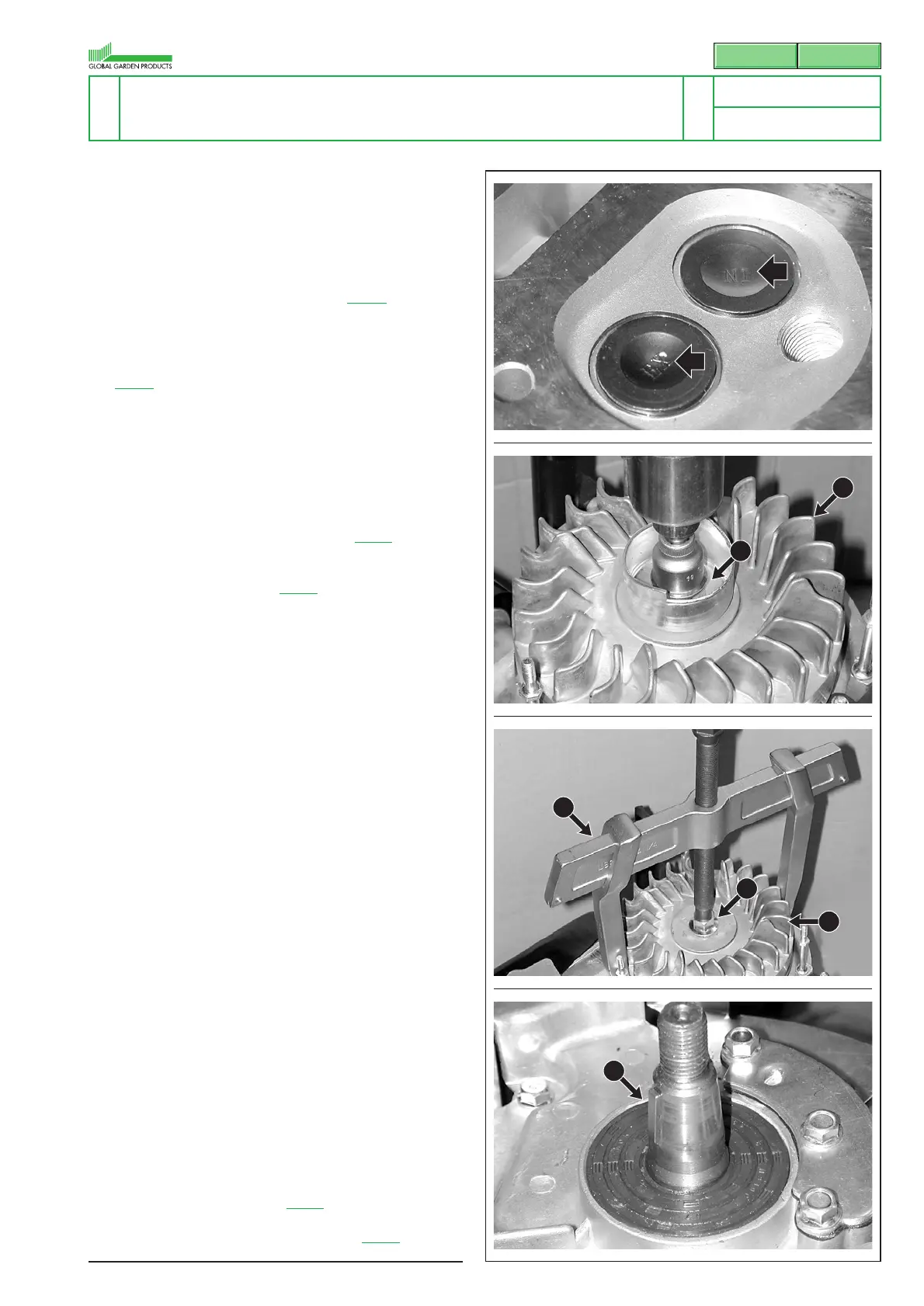

66 Remove the magneto flywheel (42) using a puller

(43) suitable for the purpose.

67 On assembly check the condition of the spline

key (44) and replace it if damaged; screw on the

nut (41) to the specified torque using a striker

gun.

68 Remount the conveyor (20).

35 Remount the tank [

6.1.A].

36 Remount the starting system [

6.2.A].

6.9.1

ENGINE BLOCK – External operations

5 / 7

SERVICE MANUAL

page

from

2007 to ••••

44

41

42

41

43

42

Loading...

Loading...