ONCE THE ENGINE IS REPAIRED CHECK THE CO% VALUE WHILE IDLING TO MAKE SURE IT

IS WITHIN THE PRESCRIBED VALUES.

IF THE CO% IS NOT IN CONFORMITY, PROCEED WITH CALIBRATION AS DESCRIBED IN THE

ADJUSTING IDLE CARBURETION CHAPTER.

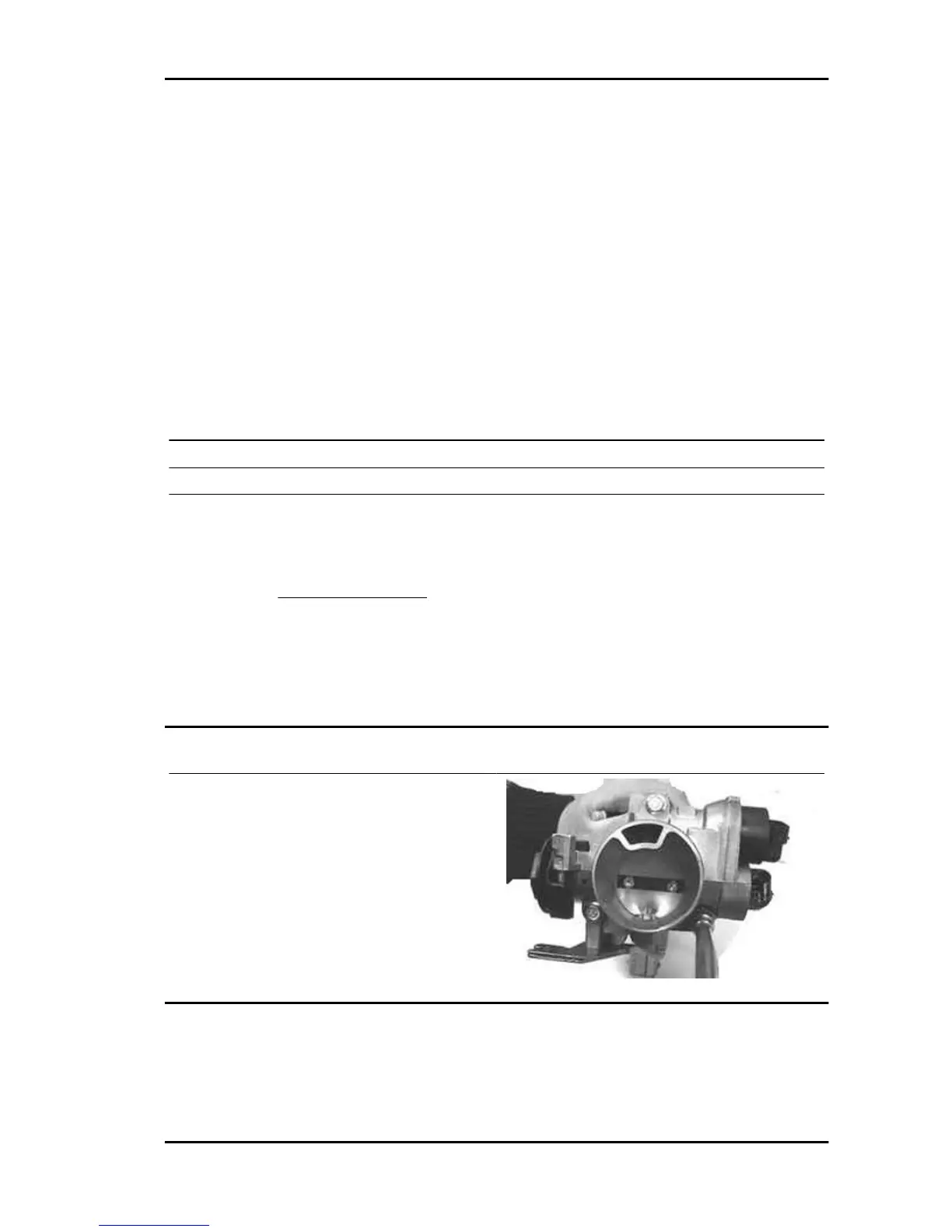

throttle body

Upon analysing the material sent and covered by the warranty, it seems several throttle bodies have

been mistakenly replaced due to valve fouling. Dirt deposited on that valve, mainly on the inlet manifold

side, can be easily removed. Once clean, the throttle body guarantees an air flow exactly the same as

the original. Throttle valve fouling is phenomenon that happens at different times depending on how

the scooter is used, weather conditions and idle speed adjustment. This phenomenon can be easily

detected as a gradual poor idle signals it. Carry out a thorough check with a scooter diagnostic tester,

drw. 020460y. With engine temperature of at least 90°, the parameters may be as follows:

Standard Dirty throttle body

Engine revs

1500±5 < 1400

Ignition advance

5°÷7° 10°

Throttle valve opening

5.24° 5.24°

The error menu displays the signals stored in the "RPM sensor". This takes place only when the engine

stops with the key switch set to "on." An exhaust fumes analysis will show a very rich and non adjustable

idle carburetion (CO > 4% - CO2 < 12%). Measure with the tool in drw. 020625y. It is evident that,

except for cases of early fouling, cleaning should not be carried out when still covered by the warranty.

After cleaning the throttle body, check and, if necessary, adjust C0. If these indications occur when the

injection warning light turns on or further errors or wrong parameters are present, it is necessary to carry

out the relevant controls indicated in the manual. In such a case, there is a real fault evidently.

Refitting the butterfly valve

- Carry out the removal operations but in reverse

order, tighten the 3 fixing screws to the prescribed

torque.

Locking torques (N*m)

Throttle body fixing screws 11 ÷ 13

Pump supply circuit

The control unit starts the pump in the following conditions:

- by setting the switch to «ON» with the emergency switch to «RUN» and side stand raised. The pump

does not supply.

Nexus 500 euro 3 Injection

INJEC - 215

Loading...

Loading...