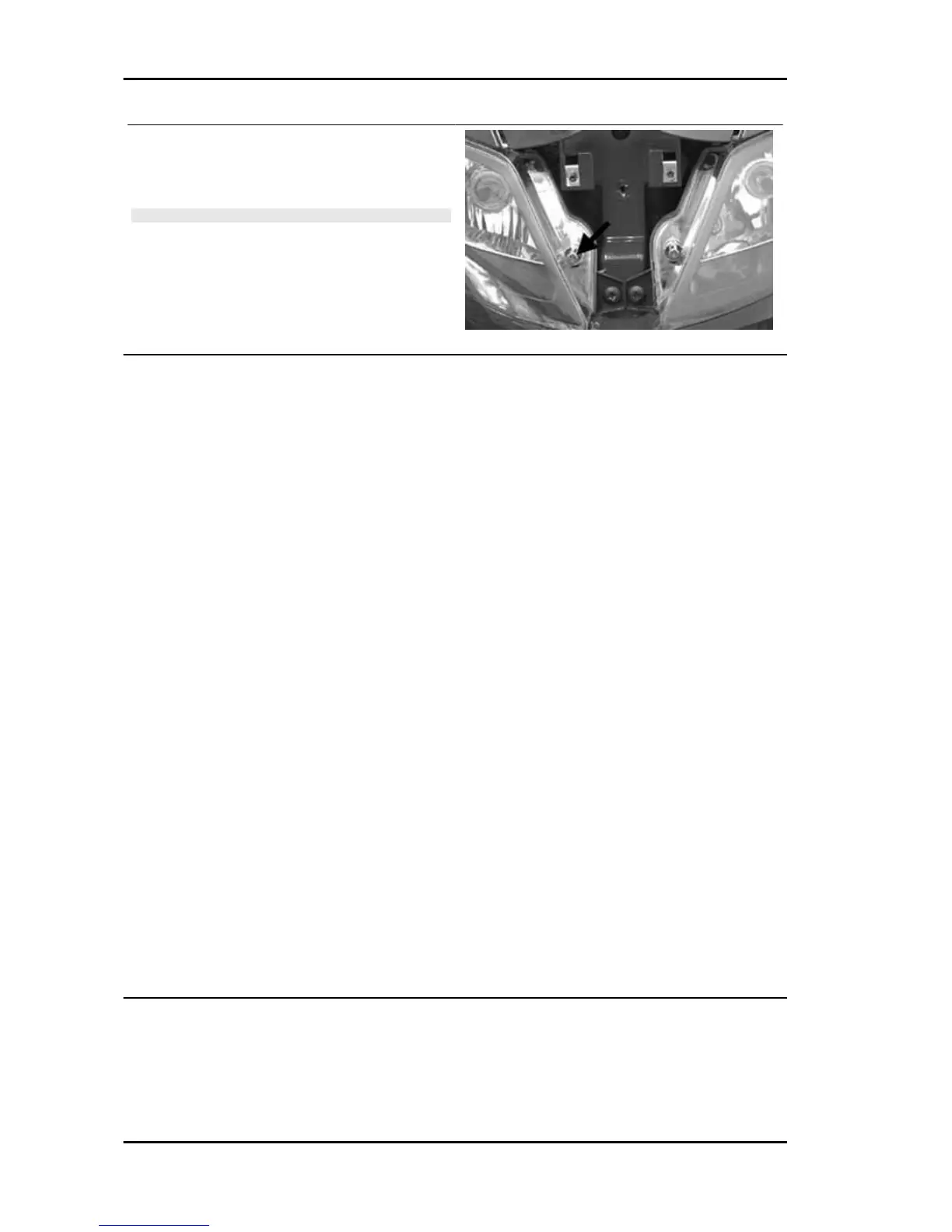

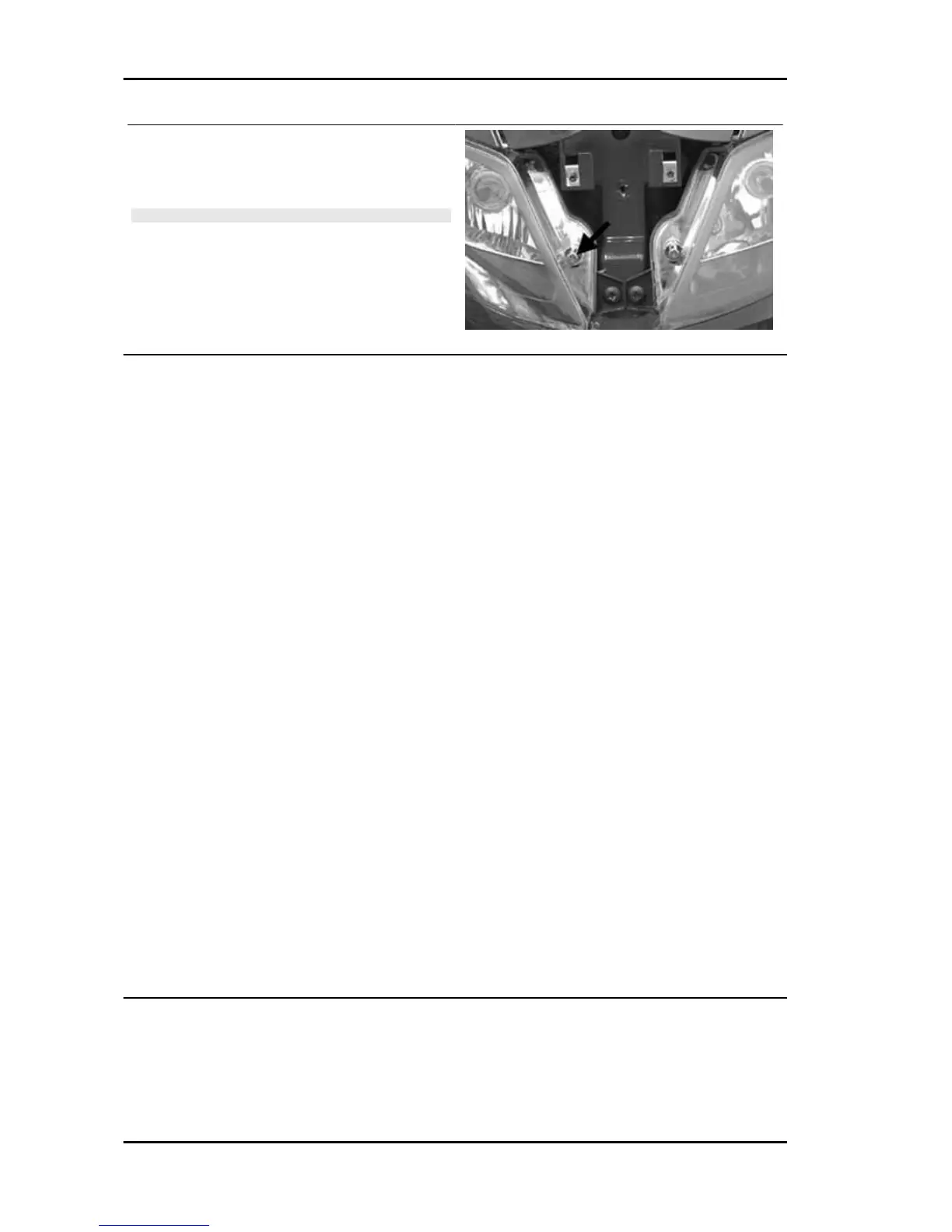

- Otherwise, adjust the right headlight by the screw

shown in the figure, which can be accessed by re-

moving the front shield connecting member.

N.B.

THE ABOVE PROCEDURE COMPLIES WITH THE EURO-

PEAN STANDARDS REGARDING MAXIMUM AND MINI-

MUM HEIGHT OF LIGHT BEAMS. REFER TO THE STATU-

TORY REGULATIONS IN FORCE IN EVERY COUNTRY

WHERE THE vehicle IS USED.

Checking the end compression pressure

- Remove the spark plug cap with the engine cold.

- Remove the spark plug.

- Fit a compression test gauge into the spark plug seat using a 10 mm spark plug union at the proper

tightening torque.

- Turn the switch to "ON", wait a few seconds and the disconnect the connector of the revolution sensor

to prevent the function of the injector and the spark plug.

- Allow the engine to run using the starter and with the throttle body in fully open position as long as the

gauge value is steady.

- If the pressure is higher than specified, remove the tool and reassemble the scooter.

- If the pressure is less than indicated, check the rpm at which the test is carried out; if it is less than

450 rpm, check the starter system.

If the final compression pressure is less than specified, remove the pressure gauge connector and inject

a few cc of oil into the combustion chamber, then turn the engine over (preferably by hand) to lubricate

the cylinder.

Repeat the compression test:

If the new value is also too low, check the valve seating.

Higher compressions on a new engine indicate poor seating of the segments.

Characteristic

Compression ratio

10.5: 1

Locking torques (N*m)

Spark plug 12 ÷ 14

Maintenance Nexus 500 euro 3

MAIN - 42

Loading...

Loading...