7 Start-up

20 Installation and maintenance instructions EASICOM 3 0020239562_02

▶ You must not start up the boiler.

Conditions: Gas flow pressure in the permissible range

▶ End the check programme P.01.

▶ Allow the boiler to cool down allowing pump overrun to

operate for a minimum of two minutes.

▶ Close the gas isolator cock (1).

▶ Remove the pressure gauge and retighten the sealing

screw (2) for the measuring nipple.

▶ Open the gas isolator cock (1).

▶ Check the measuring nipple for gas tightness.

▶ Install the front casing. (→ Page 10)

▶ Reset boiler controls for normal operation.

▶ Record the appliance gas inlet working pressure (kPa

resp. mbar) in the Benchmark gas boiler commissioning

checklist.

7.9.3 Checking the leak-tightness of the flue gas

installation and flue gas recirculation

1. Check the flue gas installation is intact in accordance

with the latest gas safe technical bulletin and informa-

tion supplied in the installation instructions.

2. For extended flue gas installations check for flue gas

recirculation using the air analysis point.

3. Use a flue gas analyser.

4. If you discover CO or CO

2

in the supply air, search for

the leak in the flue gas installation or for signs of flue

gas recirculation.

5. Eliminate the damage properly.

6. Check again whether the supply air contains any CO or

CO

2

.

7. If you cannot eliminate the damage, do not start up the

product.

7.9.4 Thoroughly flushing the heating installation

("hot")

1. Operate the appliance until the boiler and the heating

system are up to temperature.

2. Check the heating system for leaks.

3. Connect a hose to the drain valve located at the lowest

position of the heating system.

4. Shut off the boiler, open the drain valve and all purge

valves on the radiators and allow the water to flow out

of the heating system and the boiler quickly and fully.

5. Close the drain valve.

6. Fill and purge the heating installation. (→ Page 18)

7. Re-fill the system until the system design pressure of

0,1 MPa (1,0 bar) is attained.

Note

The actual reading on the digital pressure

gauge should ideally be 0,05 MPa (0,5 bar)

plus an additional pressure corresponding

to the highest point of the system above the

base of the boiler – 10 m head equals an ad-

ditional 1 bar reading on the pressure gauge.

The minimum pressure should not be less

than 0,1 MPa (1 bar) in any installation. If

the system is to be treated with an inhibitor it

should be applied at this stage in accordance

with the manufacturer’s instructions. Further

information can be obtained from Sentinel,

Betz Dearborn Ltd., Tel: 0151 420 9595, or

Fernox, Alpha– Fry technologies. Tel: 0870

8700362.

8. Install the front casing. (→ Page 10)

7.9.5 Checking the CO₂ content

1. Start up the product with the check programme (P.01)

and set the value.

– Setting value for the programme P.01: 100

Check programmes – Overview (→ Page 30)

2. Wait until the value that is read is stable.

– Waiting period for reading a stable value: 5 min

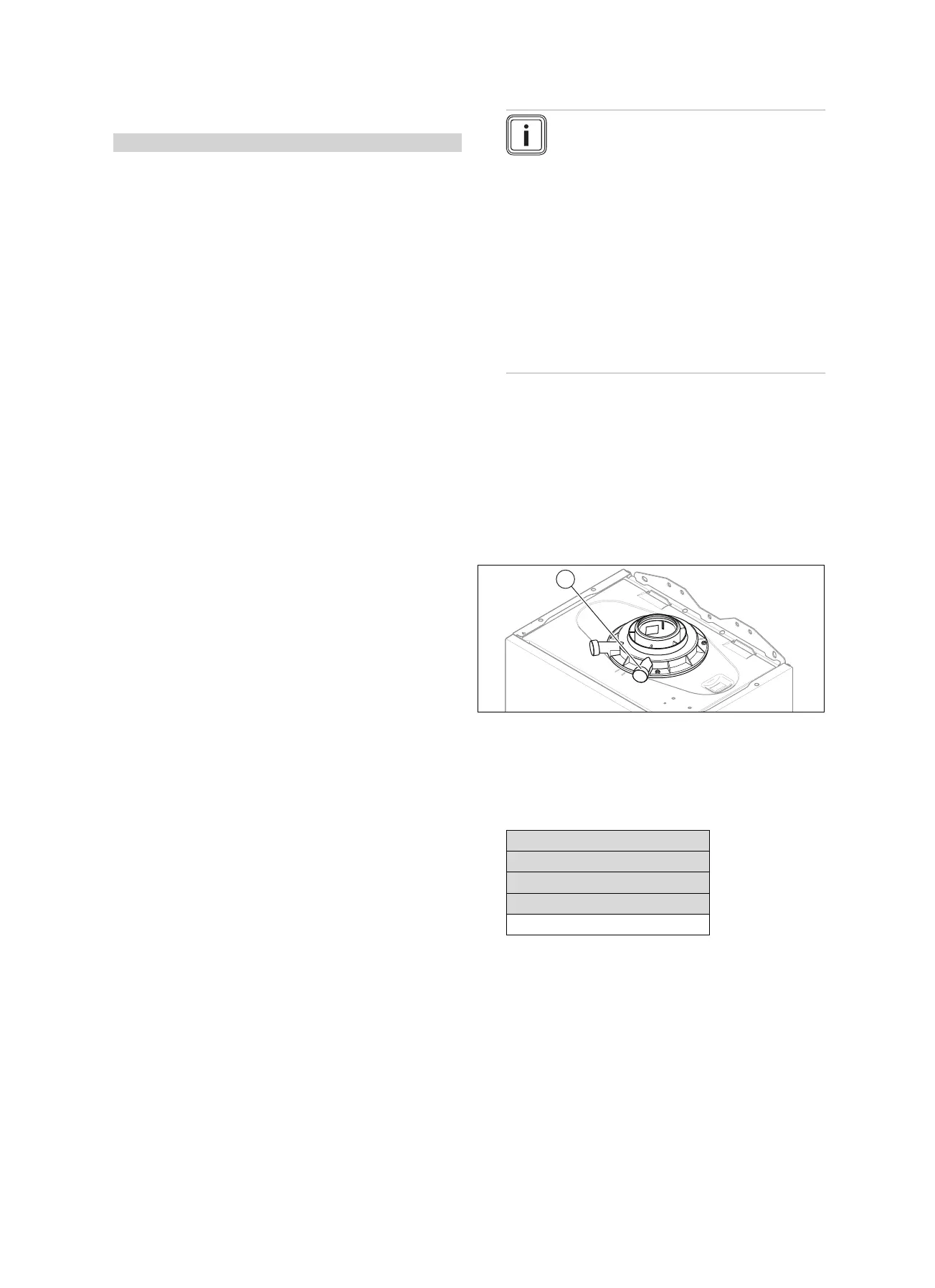

3. Unscrew the cover from the flue gas analysis point (1).

4. Measure the CO₂ content at the flue gas analysis point

(1).

5. Compare the measured value with the corresponding

value in the table.

Checking the CO₂ content

Great Britain

front casing on / front casing off

Natural gas

G20

9.2 ±1 %

◁ The value is OK.

▽ The value is not OK; you cannot start up the

product.

▶ Inform Customer Service.

Loading...

Loading...