Adapting the unit to the installation 8

0020283671_03 Energy 2 Installation and maintenance instructions 21

Status codes – Overview (→ Page 33)

◁ If the product is working correctly, the display shows

S.14.

8 Adapting the unit to the installation

You can reset/change the system parameters (section "Us-

ing diagnostics codes").

Overview of diagnostics codes (→ Page 29)

8.1 Setting the burner anti-cycling time

To prevent frequent switching on and off of the burner and

thus prevent energy losses, an electronic restart lockout

is activated for a specific period each time the burner is

switched off. The burner anti-cycling time is only active for

the heating mode. Domestic hot water mode during a burner

anti-cycling time does not affect the time function element.

8.1.1 Setting the maximum burner anti-cycling

time

1. Set diagnostics code . (→ Page 15)

Overview of diagnostics codes (→ Page 29)

2. If required, adjust the maximum burner anti-cycling time

using the diagnostics code d.02.

8.1.2 Resetting the remaining burner anti-cycling

time

▶ Hold the button down for more than 3 seconds.

◁ is shown in the display.

8.2 Setting the pump output

The product is equipped with a speed-regulated high-effi-

ciency pump, which adjusts independently to the hydraulic

conditions of the heating installation.

If you have installed a low loss header in the heating install-

ation, you should switch off the speed regulation and set the

pump output to a fixed value.

▶ If required, change the setting of the pump speed, which

depends on the operating mode, under diagnostics code

d.14.

▶ Set diagnostics code . (→ Page 15)

Overview of diagnostics codes (→ Page 29)

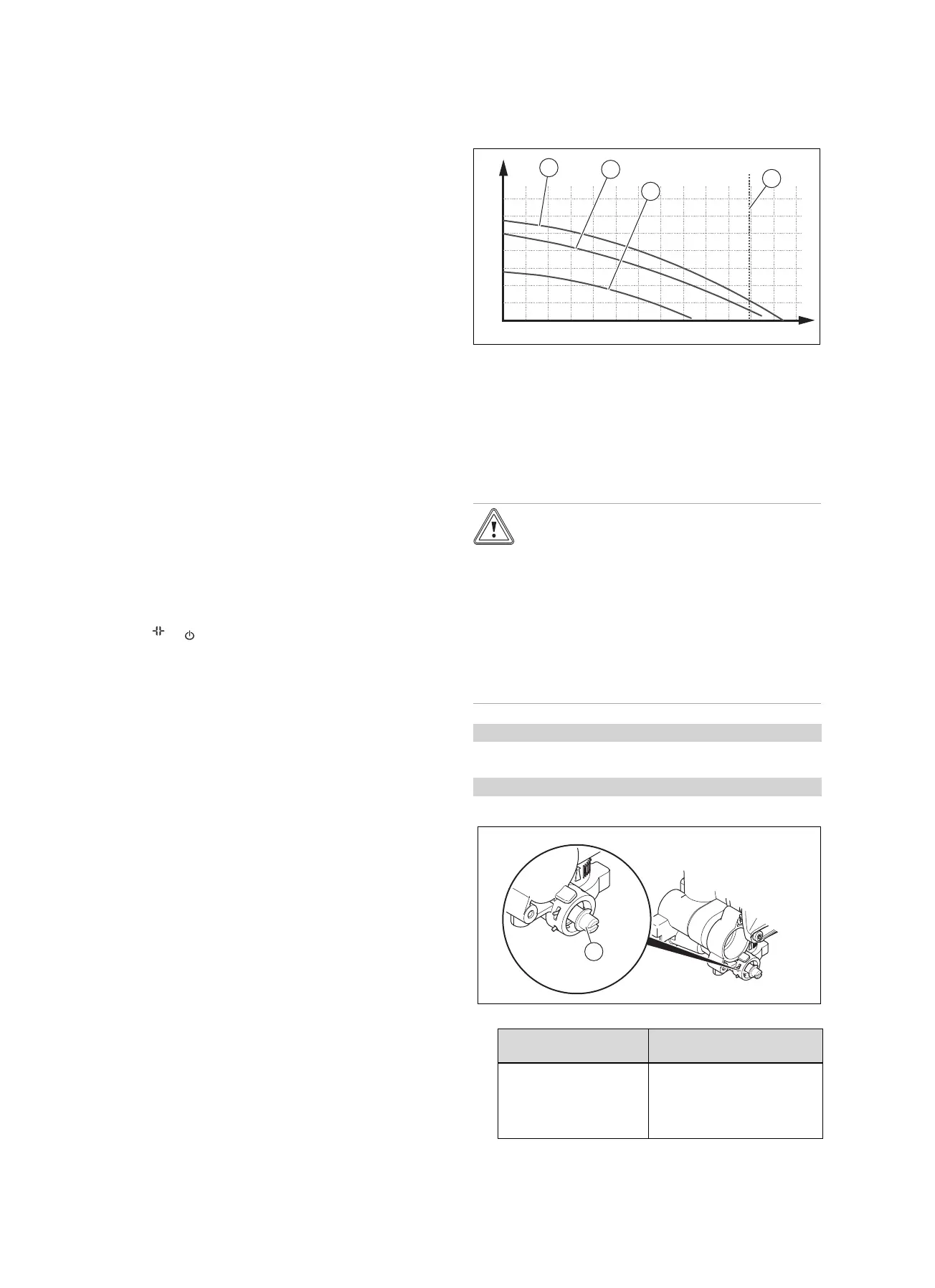

Flow rate-pressure curves for 30 kW

(pressure measured downstream of the valves)

A

B

0

10

20

30

40

50

60

0 200 400 600 800 1000 1200

70

1

2

3

4

1 Maximum speed (by-

pass closed)

2 Maximum speed (de-

fault setting for the by-

pass)

3 Minimum speed (factory

setting for the bypass)

4 Flow rate at maximum

output (ΔT = 20K)

A Throughput in circuit

(l/h)

B Available pressure

(kPa)

8.3 Setting the bypass valve

Caution.

Risk of material damage caused by incor-

rect setting of the high-efficiency pump

If the pressure at the bypass valve is in-

creased (by turning it clockwise) and the

pump output is set to less than 100%, the

product may not operate correctly.

▶ In this case, set the pump output to

5 = 100% using diagnostics parameter

d.14.

Condition: d.14 is set to 0 = auto

▶ Do not change the factory settings.

Condition: d.14 is set to 1 - 5

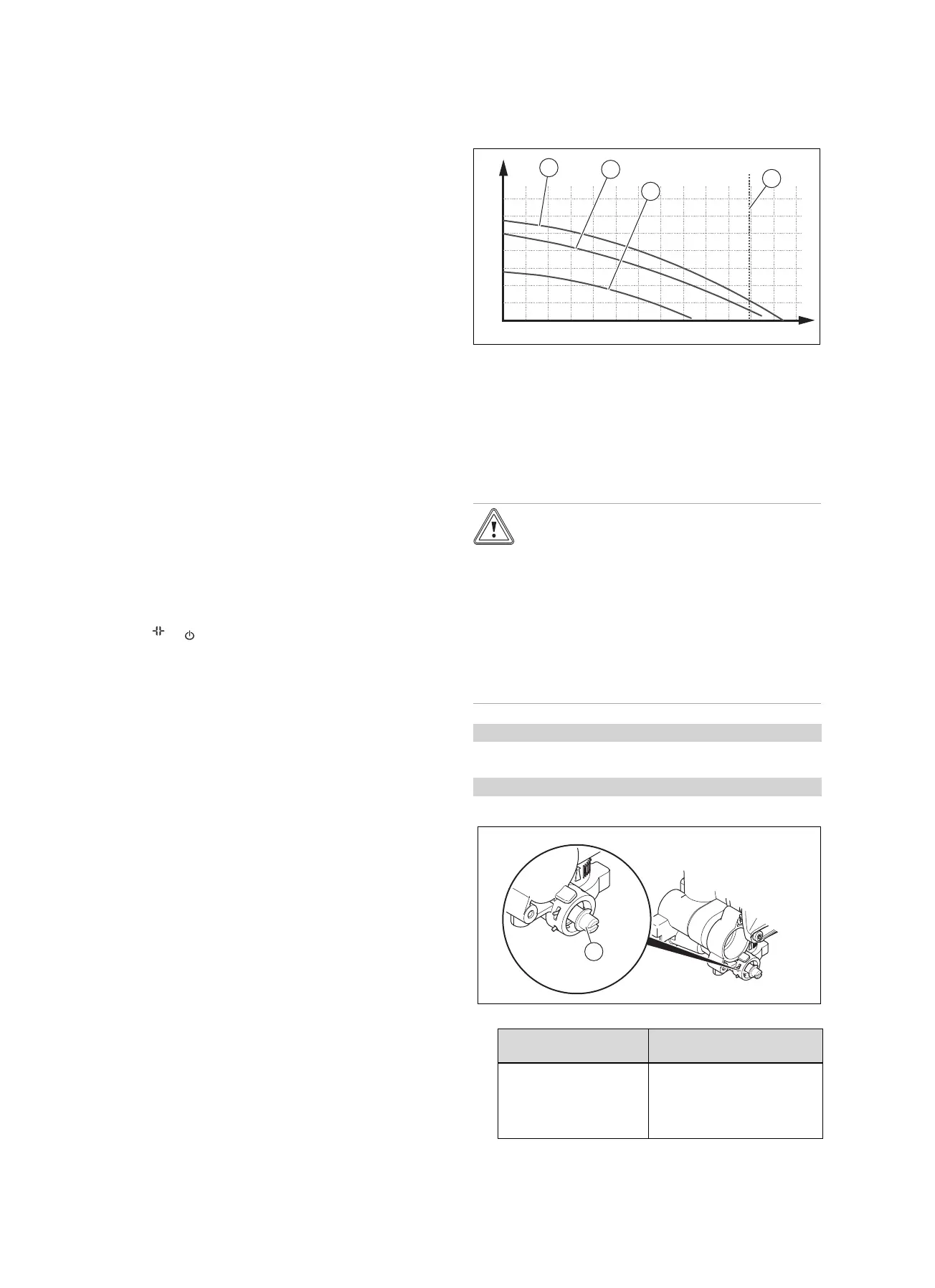

▶ Remove the front casing. (→ Page 10)

▶ Regulate the pressure using the adjusting screw (1).

Position of the adjusting

screw

Notes/application

Right-hand stop (screwed

all the way in)

If the radiators do not heat

up sufficiently at the default

setting. In this case, you must

set the pump to the maximum

speed.

Loading...

Loading...