Supplied By www.heating spares.co Tel. 0161 620 6677

0020085231_02 - 05/10 - Glow-worm

- 35 -

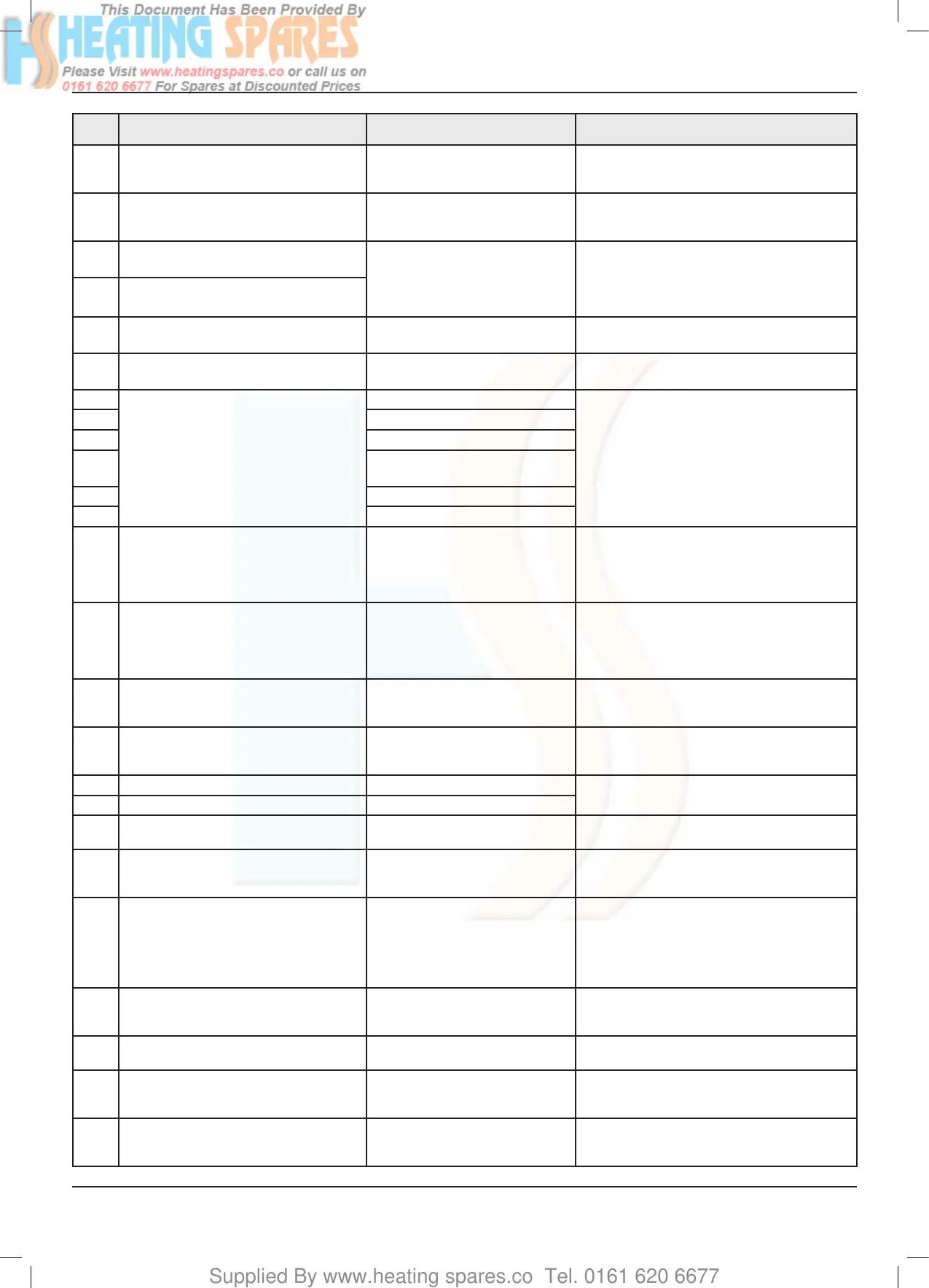

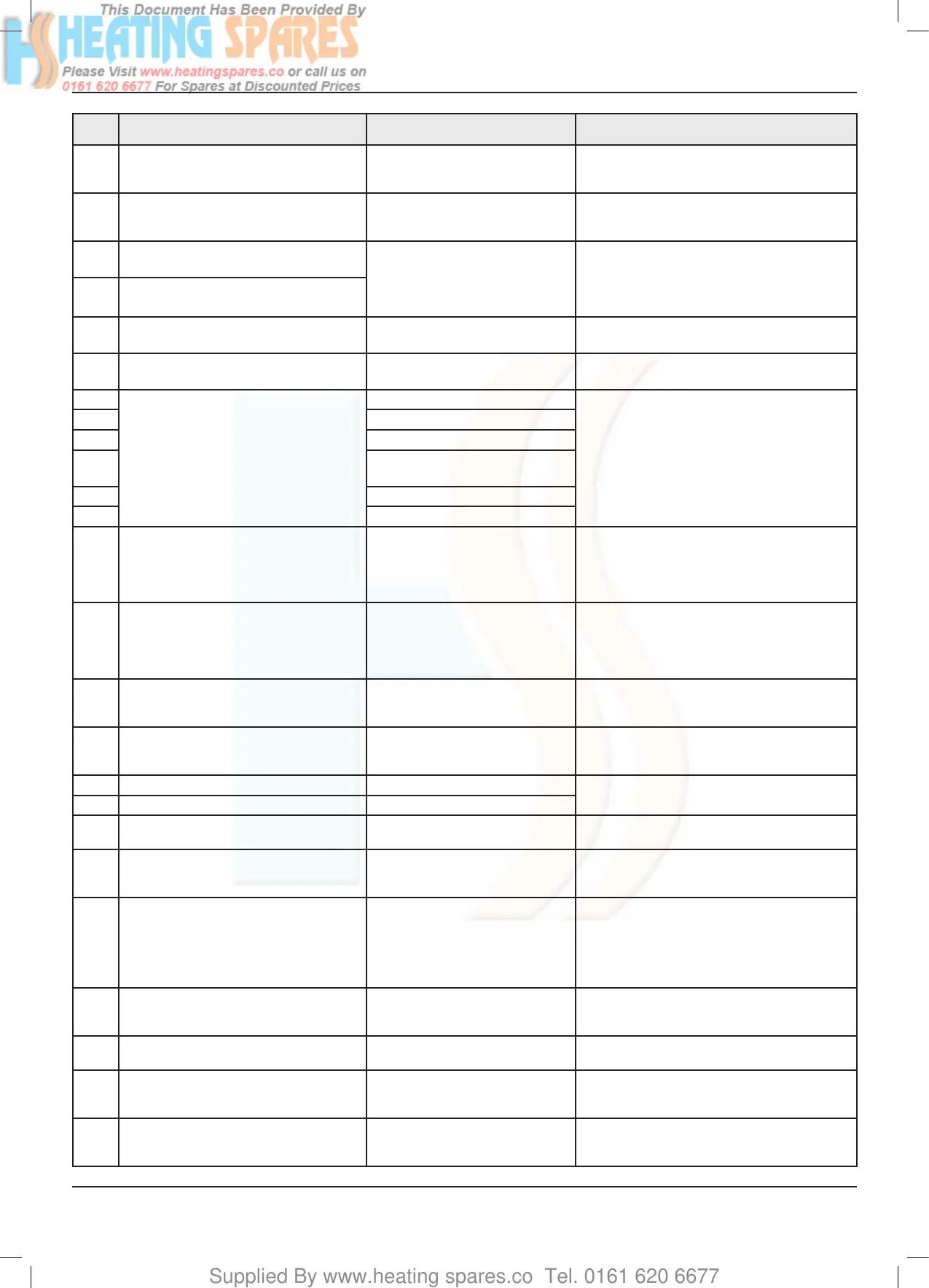

Fault

codes

Description Cause Solution

F26 Fault in gas valve motor. Disconnected or defective cables

• Check the gas valve connections.

• Check the operation of the gas valve.

• Check the operation of the condensate pump (option).

F27 Flame detection fault. Abnormal ame detection

• Check the ame detection electrode.

• Check the main board.

• Check the igniter unit.

F28 Ignition fault

No return gas / Insufcient gas ow

Gas valve incorrectly adjusted

Defective ring electrode and ame

control / Defective igniter unit

• Check the return gas circuit (gas valve open).

• Check the observe the ame picture and check

the CO

2

setting.

• Check the igniter unit connections.

• Check the state of the electrode (corrosion).

F29 Loss of ame during operation

F32 Incorrect air pressure Incorrect fan speed.

• Check the entire ue system.

• Check the fan’s electrical connections.

F49 EBUS voltage fault

Fault in EBUS line

Short circuit in EBUS connector

• Check that the eBus controls are tted and wired

correctly.

F61

Fault in the main board

Gas valve command fault

• Check the main boards connections.

• Check the main board.

• Check the appliance DSN number is correct.

• Reset the appliance.

F62 Gas valve closure fault

F63 Fault in the main board memory

F64

Rapid uctuation of return or ow

heating sensor.

F65 Excessive main board temperature

F67 Flame signal fault in the main board

F68 Fluctuation of ame signal

No return gas / Insufcient gas ow

Gas valve incorrectly adjusted

Defective ring electrode and ame

control / Defective igniter unit

• Check the return gas circuit (gas valve open).

• Check the observe the ame picture and check

the CO

2

setting.

• Check the igniter unit connections.

• Check the state of the electrode (corrosion).

F70

User interface incompatible with the main

board

Incorrect product code

• Check that the appliance DSN code on the screen

matches the product code of the nameplate (in the

event of a fault and the appliance DSN does not

appear, consult menu.d.93 reserved for the code).

• Check the boards reference.

F71 Flow heating temperature sensor fault

Flow heating temperature sensor

unclipped or defective (no

temperature variation)

• Check the sensor connections.

• Make sure that the sensor is clipped to the tube.

F72

Permanent temperature difference between

ow and return heating sensors

Mismatch between the ow and return

heating temperatures (permanent

difference)

• Check temperature sensors connections.

• Replace faulty sensors.

F73 Heating circuit pressure sensor fault The sensor is shorted or disconnected.

• Check the sensor’s connections.

• Check the sensor.

F74 Heating circuit pressure sensor fault Fault in pressure sensor

F76 Thermal fuse fault

Thermal fuse disconnected

Defective thermal fuse

• Check the fuses connections.

• Replace the heat exchanger.

F77 Fault in gas valve motor.

Defective gas valve.

Defective condensate pump (option)

• Check the gas valve connections.

• Check the operation of the gas valve.

• Check the operation of the condensate pump (option).

F83

No water in the installation : the temperature

does not increase when the burner is lit

Return water valve closed

Pump disconnected

Leak in the installation

• Fill the installation.

• Purge the installation.

• Check the pump connections.

• Check the ow and return heating sensor

connections.

• Check that there are no leaks.

F84

Permanent temperature difference between

ow and return heating sensors

Inverted or disconnected ow and

return heating temperature sensors

Defective temperature sensors

• Check temperature sensors connections.

• Replace faulty sensors.

F85 Flow and return heating sensors fault

Flow and return heating temperature

sensor connected to same tube

• Check temperature sensors connections.

F86 Underoor heating contact fault

Floor heating contact open

Sensor disconnected or defective

• Check the sensor connections.

• Check that the sensor is connected to the main

board and the shunt is removed.

Err User interface fault Defective user interface

• Check connection from user interface PCB to main

PCB.

• Replace user interface.

MAINTENANCE

Loading...

Loading...