Glow T180

Tankless Condensing Water Heater

50

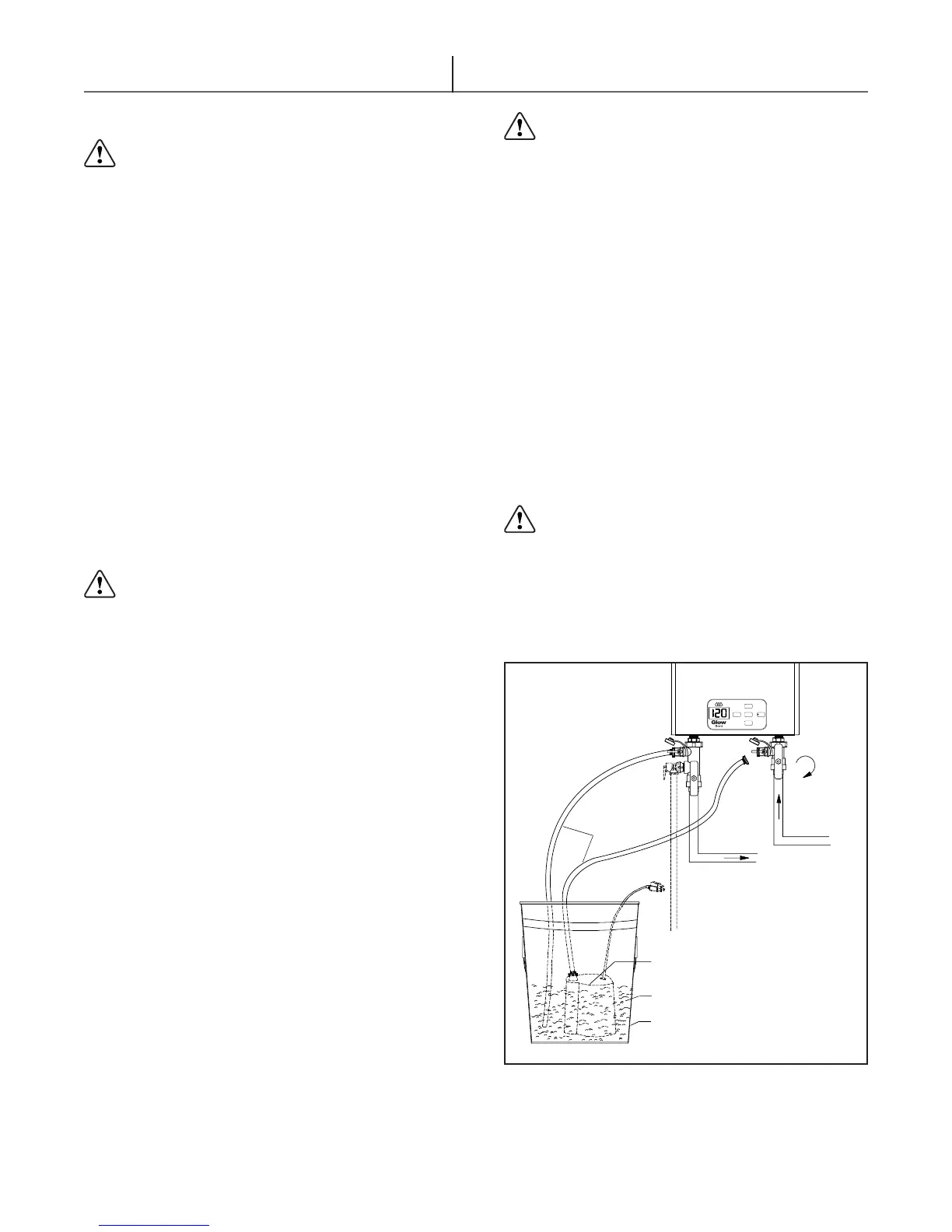

5.3 De-scaling and ushing

CAUTION! Before unthreading the hose

caps for any reason, make sure the drain valves

are CLOSED. Unthread slowly, to allow any built-

up pressure to disperse. After removing the cap,

inspect the cap’s gasket for damage. Replace as

necessary.

Glow T180

WASHING

MACHINE

HOSES

PUMP

5 GALLON BUCKET

OVERFLOW TUBE

DOMESTIC HOT

WATER OUT

DOMESTIC COLD

WATER IN

ROTATE

CLOCKWISE

FOR SERVICE

WHITE VINEGAR

MENU

UP

ENTER

DOWN

RESET

5.2 Maintenance

Δ Periodic examination of the entire venting

system is recommended.

Δ Ensure all venting connections/joints are tight

and in good condition where visible.

Δ Remove the burner along with the motor and

gas valve as one complete assembly.

Δ When doing so, visually inspect the burner

and components for signs of ware or irregular

characteristics. This would include the ignition

and ionization.

Δ Reassemble the complete burner assembly.

Δ Visually inspect the burner ame. The ame

must burn with a clear blue, stable ame when

in operation.

Δ All electric motors are permanently lubricated

and do not need oiling.

Δ Verify proper operation after any servicing.

Δ Wipe the outside surface with a wet cloth; then

dry the surface.

Δ Vent termination should be inspected for

blockage during maintenance checks.

Δ Check for blockage at the drain pipe and

condensate trap.

Δ Check for water leaks from the equipment and

piping.

Δ Warranty will not be offered if recommended

maintenance is not followed.

Δ All maintenance operations must be carried out

by professionally qualied personnel, authorized

by Glow Brand.

Δ The frequency of water heater maintenance is

recommended to be carried out once a year.

Δ In order to guarantee the long life of the

appliance and in accordance with the current

gas safety regulations, only use original OEM

parts.

Δ Before carrying out any type of maintenance

operation, disconnect the appliance from the

electrical supply and shut off the gas valve.

Δ Warranty will not be offered if recommended

maintenance is not followed.

Δ Remove and clean any deposits from the burner.

Δ Check that the seal of the room-sealed chamber

is undamaged and positioned correctly.

Δ Check the heat exchanger and clean if

necessary.

5. Maintenance (Authorized Personnel)

5.1 General Warnings

CAUTION! Before pressurizing

the system for service, ALWAYS make

sure the drain valves of both HOT and

COLD isolation valve assemblies are

placed in the CLOSED position, where

the drain valves’ stem slot is positioned

perpendicular to the drain valves’ body.

Remove the hose caps and visually

inspect the drain valve outlets to verify

that the balls are in the closed position.

You should see the chrome-plated face

of a closed ball. You should NOT be able

to see into the body of the drain valve.

Replace the hose caps and hand-tighten

only.

Figure 5.1 - Flushing the water heater

Loading...

Loading...