14

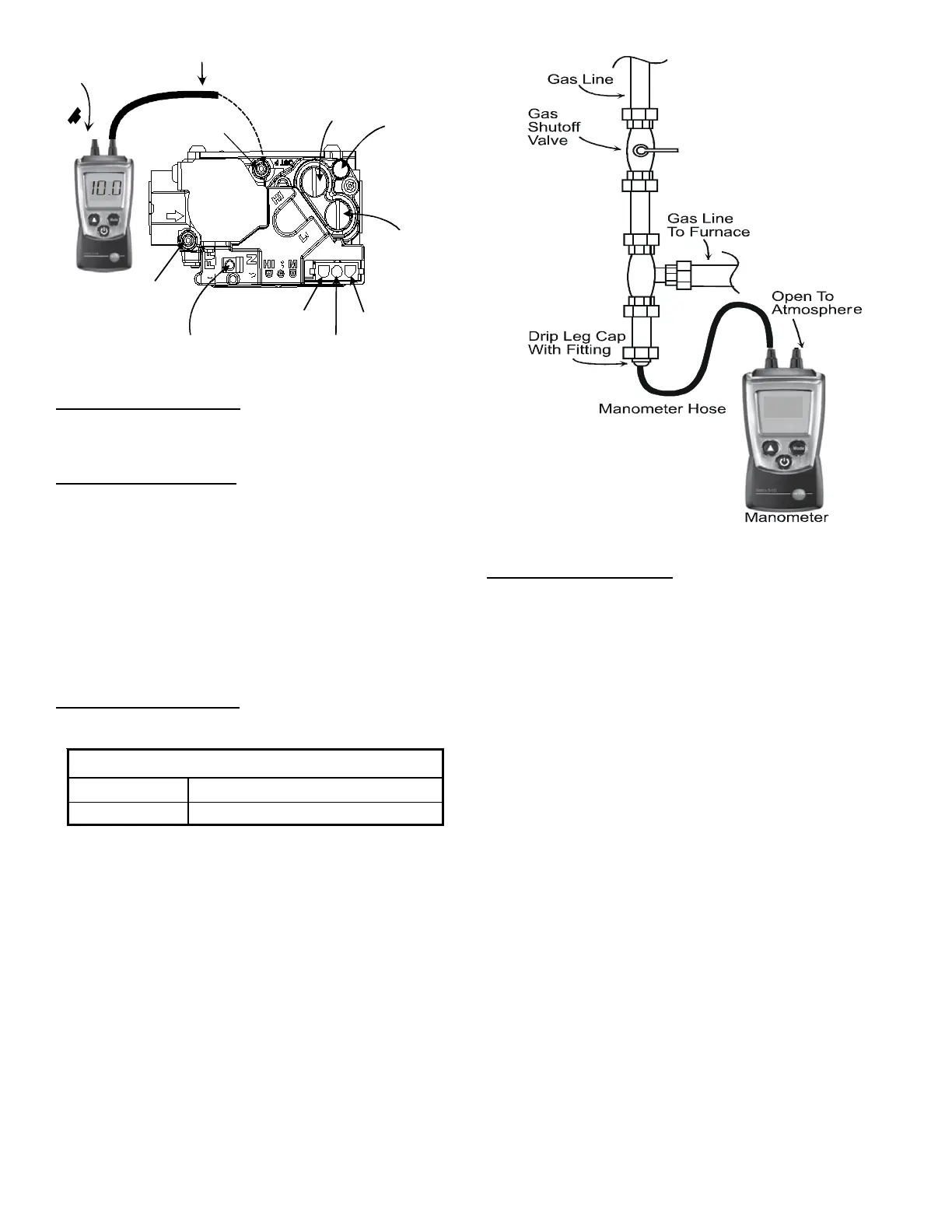

On/Off Switch

Inlet

Pressure Boss

High Fire

Coil Terminal (HI)

Low Fire

Regulator Adjus

Manometer

Manometer

Hose

A

High Fire Regulator

Adjust

Regulator

Vent

Common

Coaxial Coil

Terminal (M)

Outlet

Pressure Boss

Gas inlet pressure must be checked and adjusted in accor-

dance to the type of fuel being consumed.

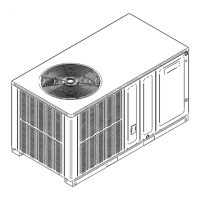

: Use adapter kit #0151K00000S to measure gas pres-

sure on White-Rodgers 36G54 gas valves.

1.

-

ternately, inlet gas pressure may be measured by remov-

ing the cap from the drip leg and installing a predrilled cap

2. Connect a water manometer or adequate gauge to the

3. Put unit into heating cycle and turn on all other gas con-

suming appliances.

Natural Min. 5.0" W.C., Max. 10.0" W.C.

Propane Min. 11.0" W.C., Max. 13.0" W.C.

INLET GAS PRESSURE

Inlet Gas Pressure Must be within the Minimum and Maximum Value

Shown in Table Above.

Inlet Gas Pressure must be within the minimum and

not exceed the maximum value shown. If operating pressures

-

ments, check piping size, etc., and/or consult with local utility.

4.

5. Remove manometer hose from the outlet pressure

6. Turn inlet pressure test screw in to seal pressure port

-

drilled cap from drip leg. Reinstall original cap, sealing

with pipe thread compound.

7. Turn on electrical power and gas supply to the system.

8. Turn on system power and energize valve.

9. Using a leak detection solution or soap suds, check for

-

bles forming indicate a leak. SHUT OFF GAS AND FIX

ALL LEAKS IMMEDIATELY.

.

1.

valve external to the furnace.

2.

3.

4. Attach a hose and manometer to the outlet pressure

boss of the valve.

5. Turn ON the gas supply.

6.

energize the HI solenoid.

7. -

just manifold pressure using the Manifold Gas Pres-

sure table.

8.

pressure regulator adjust tower and turn screw clock-

wise to increase pressure, or counterclockwise to de-

crease pressure.

9.

10. Remove regulator cover screw from the HI outlet pres-

sure regulator adjust tower and turn screw clockwise

to increase pressure, or counterclockwise to decrease

pressure.

11.

12. Remove manometer hose from outlet pressure boss.

13. Turn outlet pressure test screw in to seal pressure port

14. Turn on electrical power and gas supply to the system.

15. Turn on system power and energize valve.

16. Using a leak detection solution or soap suds, check

for leaks at pressure boss screw. Bubbles forming in-

dicate a leak. SHUT OFF GAS AND FIX ALL LEAKS

IMMEDIATELY.

Loading...

Loading...