8

D’installation de ce générateur de chaleur à des altitudes

-

ment auxinstructions accompagnant la trousse de conver-

sion pour haute altitude fournie avec cet appareil.

The gas/electric units naturally derate

can cause poor combustion and equipment failure. At all alti-

tudes, the manifold pressure must be within 0.3 inches W.C.

of that listed on the nameplate for the fuel used. At all alti-

tudes and with either fuel, the air temperature rise must be

within the range listed on the unit nameplate. Contact your

to the Installation Manual provided with the high altitude kit

for altitude adjustments.

No changes are required up to 2,000 feet. Use the

appropriate high altitude kit above 2,000 feet.

To avoid possible unsatisfactory opera-

do not undersize the natural/propane gas piping from the

meter/tank to the unit. When sizing a trunk line, include all

appliances on that line that could be operated simultaneously.

The rating plate is stamped with the model number, type of

gas and gas input rating. Make sure the unit is equipped to

operate on the type of gas available. The gas line installa-

tion must comply with local codes, or in the absence of local

codes, with the latest edition of the National Fuel Gas Code

NFPA 54/ANSI Z223.1.

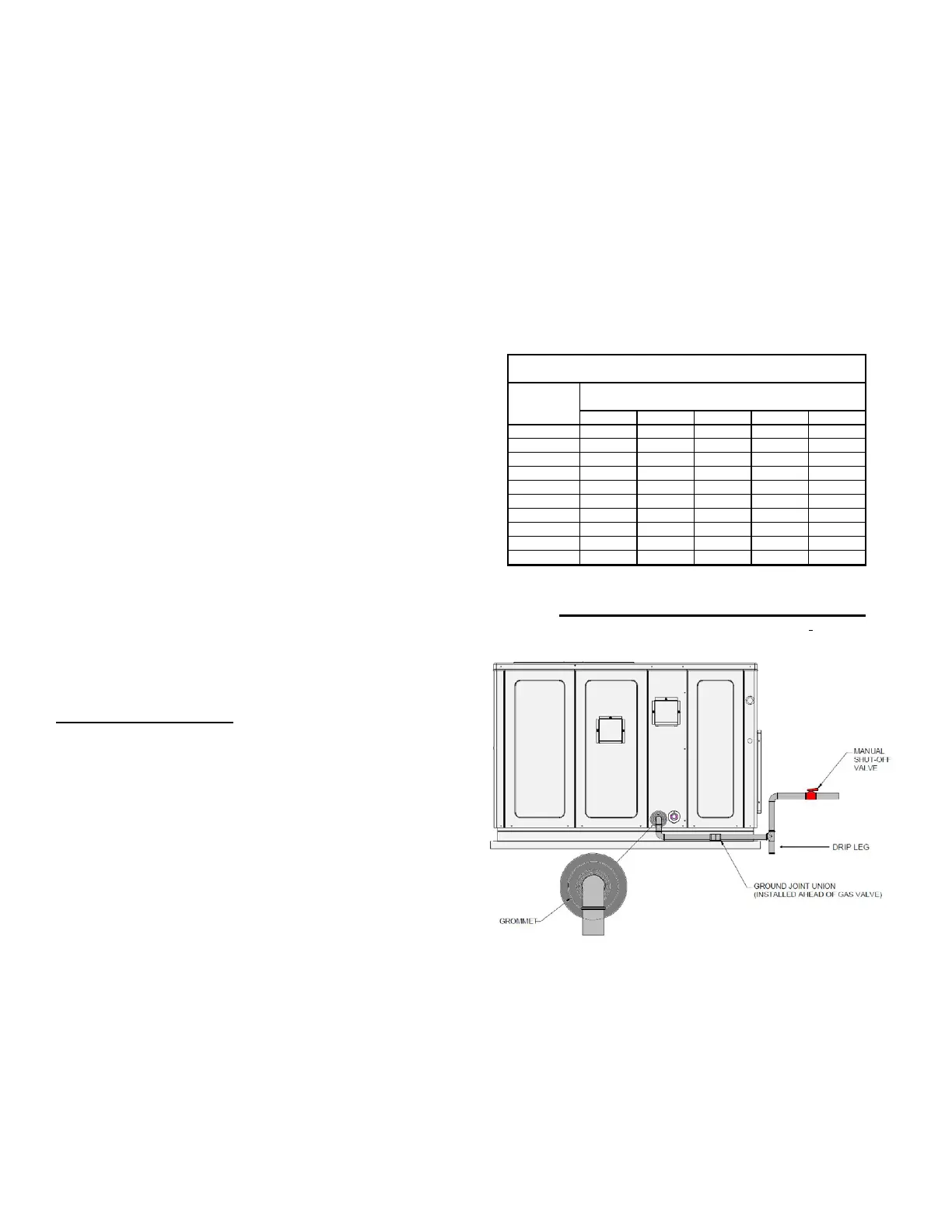

Refer to the Proper Piping Practice drawing for the general

layout at the unit. The following rules apply:

1.

-

mitted as long as it is in agreement with local codes.

2. Use pipe joint compound on male threads only. Pipe

joint compound must be resistant to the action of the

fuel used.

3. Use ground joint unions.

4. Install a drip leg to trap dirt and moisture before it can

enter the gas valve. The drip leg must be a minimum of

three inches long.

5. Use two pipe wrenches when making connection to the

gas valve to keep it from turning.

6.

7. Tighten all joints securely.

8. The unit must be connected to the building piping by

one of the following methods:

•

• -

• Listed gas appliance connectors used in accordance

with the terms of their listing that are completely in the

same room as the equipment

• In the prior two methods above the connector or tubing

must be protected from physical and thermal damage.

Aluminum alloy tubing and connectors must be coated

to protect against external corrosion when in contact

with masonry, plaster or insulation or are subject to re-

-

The unit gas supply entrance is factory sealed with

plugs. Keep plugs in place until gas supply is ready to be

installed. Once ready, replace the plugs with the supplied

grommets and install gas supply line.

Len

th of

Pipe in Feet

1/2 3/4

1

1 1/4 1 1/2

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 980

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

90 40 84 160 320 490

100 38 79 150 305 460

Pressure = .50 PSIG or less and Pressure Drop of 0.3" W.C. (Based

on 0.60 Specific Gravity Gas)

Natural Gas Capacity of Pipe

in Cubic Feet of Gas Per Hour (CFH)

Nominal Black Pipe Size (inches)

BTUH Furnace Input

Heatin

Value of Gas

BTU/Cubic Foo t

CFH =

There will be air in the gas supply line after testing for leaks

on a new installation. Therefore, the air must be bled from

the line by loosening the ground joint union until pure gas is

has been dissipated in the air. Be certain there is no open

is placed in operation by closing the main electrical discon-

nect switch for the unit.

Loading...

Loading...