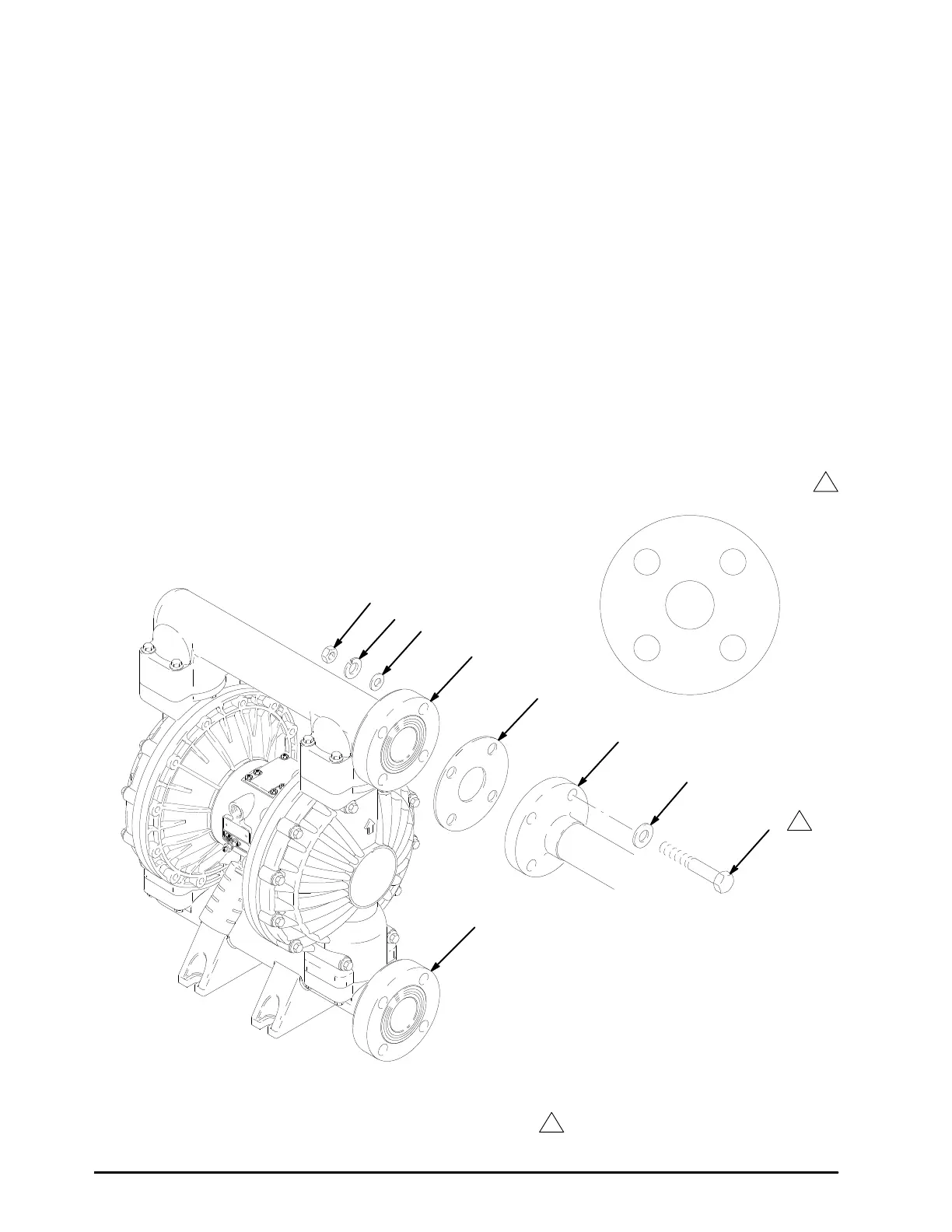

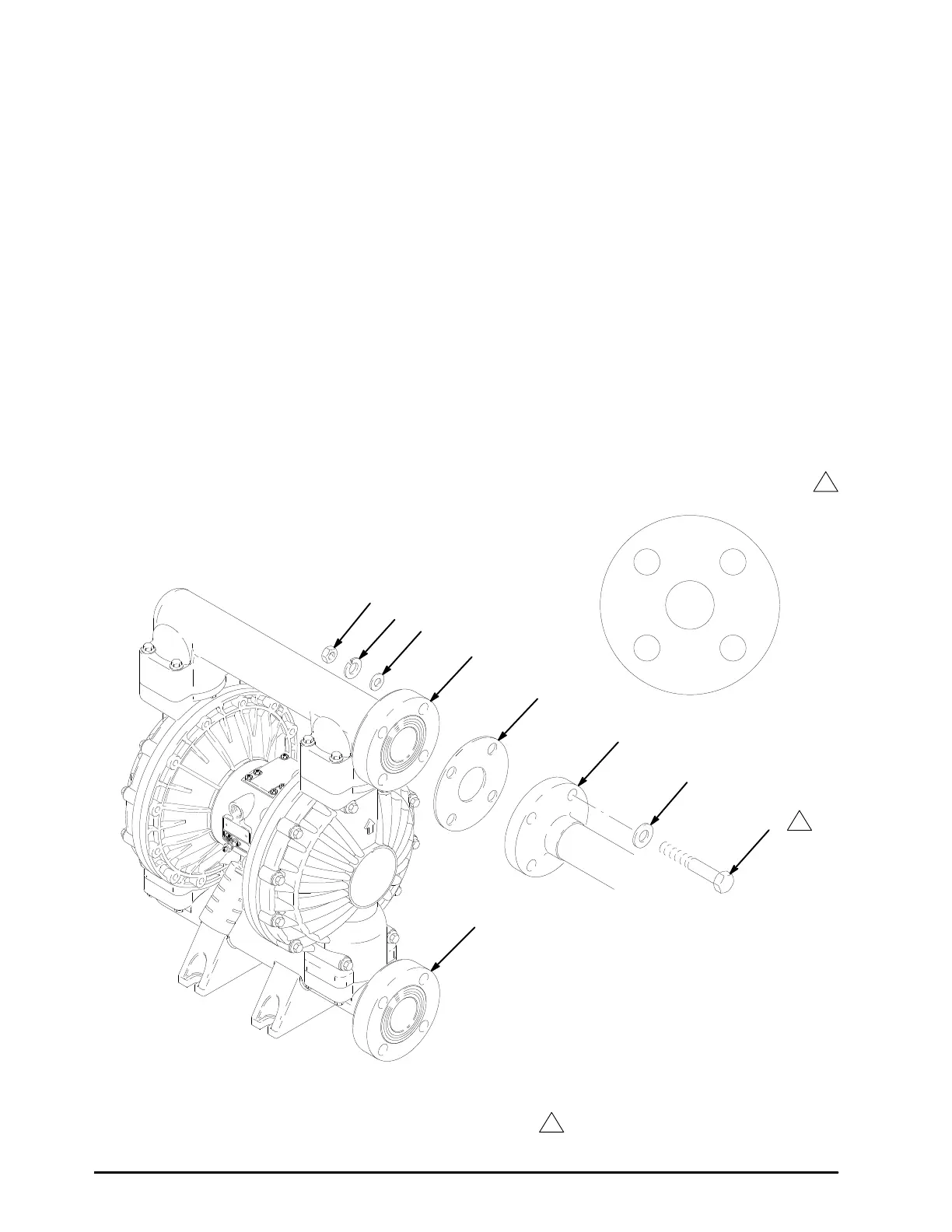

Installation

Flange Connections

The

fluid inlet and outlet ports are 2” raised face,

standard 150 lb class pipe flanges. Connect 2” flanged

plastic pipe to the pump as follows. You will need:

T

orque wrench

Adjustable wrench

6” diameter

, 1/8” thick T

eflon gasket, with four 0.75”

diameter holes on a 4.75” diameter bolt circle, and

a 2.20” diameter center

Four 5/8” x 3” bolts

Four 5/8” spring lockwashers

Eight 5/8” flat washers

Four 5/8” nuts.

1.

Place a flat washer (E) on each bolt (C). Refer to

Fig. 3.

2.

Align the holes in the gasket (B) and the pipe

flange (A) with the holes in the pump outlet

flange (S).

3.

Lubricate the threads of the four bolts. Install the

bolts through the holes and secure with the wash

-

ers (E), lockwashers (D), and nuts (F).

4.

Hold the nuts with a wrench. Refer to the tighten

-

ing sequence in Fig. 3 and torque the bolts to

20–30 ft–lb (27–41 N.m).

Do not over-torque.

5.

Repeat for the pump inlet flange (R).

04405

04615

Fig. 3

1

F

E

S

B

A

E

D

C

R

BOL

T TIGHTENING SEQUENCE

1

Lubricate

threads. T

orque to 20–30 ft–lb

(27–41 N.m). Do not over-torque.

1

2

3

4

KEY FOR FIG. 3

A

Flanged plastic pipe

BT

eflon gasket

C Bolt

D Lockwasher

E

Flat washer

F Nut

R

2” fluid inlet flange

S

2” fluid outlet flange

1

Loading...

Loading...