Installation

8 3A9522A

Installation

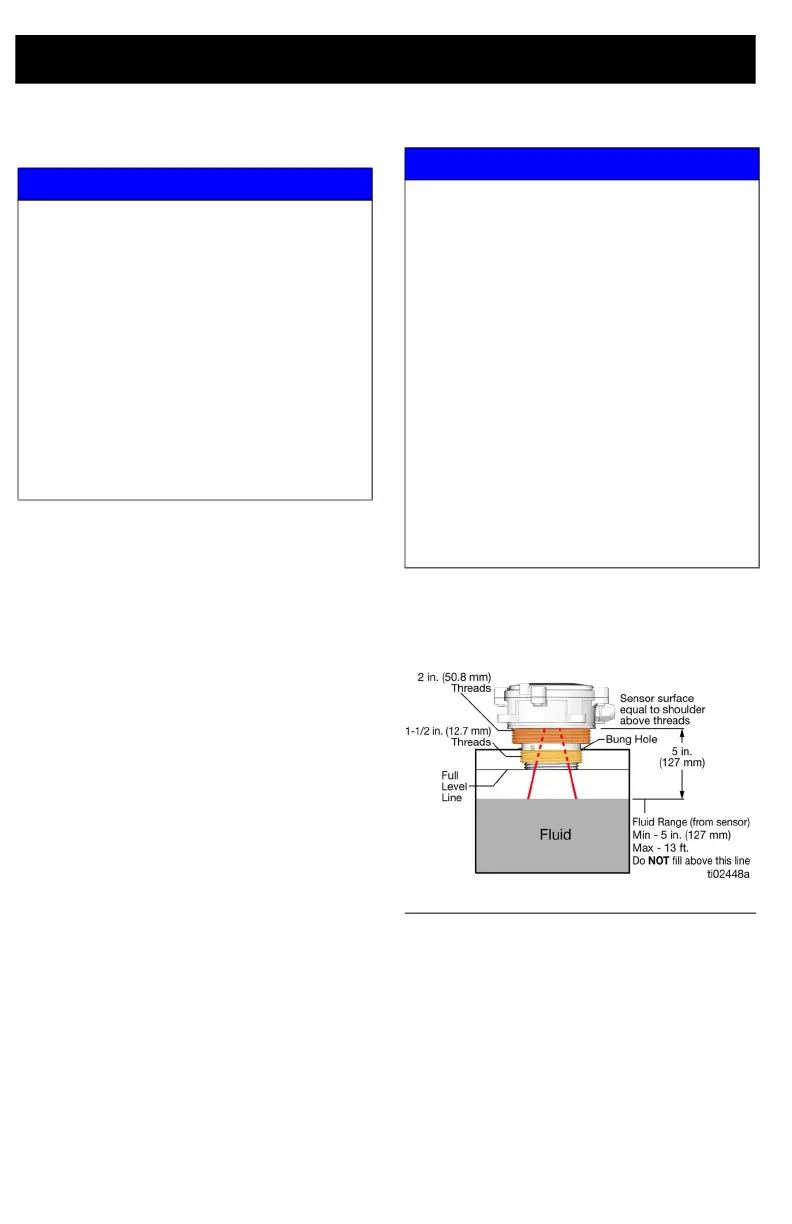

1. Remove the bung fitting and screw in

the TLM, hand-tighten.

• Do not use a wrench, as this may

damage the TLM.

• Do not use thread lock adhesive, as

this may damage the TLM.

2. Mount the TLM as close as possible to

the center of the tank.

3. Do not mount any fittings or T connects

between the TLM and the tank.

NOTICE

Do not over tighten TLM into tank bung!

Over tightening can cause permanent

damage and result in inaccurate readings.

Do not use thread sealant or adhesive!

Many of these products are chemically

incompatible with the PULSE/ABS plastic.

PTFE tape is acceptable.

Do not locate TLM next to the tank wall.

The wall can interfere with the sensor’s 30

degree cone angle.

Do not install the TLM in the tank’s fill

port. Repeated removal of the TLM will

damage the unit and void the warranty.

NOTICE

The TLM will not operate correctly if tilted

more than 2 degrees from the surface of

the tank liquid.

The TLM will not operate correctly if the

TLM is mounted less than 5 in. (127 mm)

from the maximum possible fill height of

the fluid being measured.

The TLM will not read properly if:

• Fluid in the tank is agitated (e.g. filling

a tank with oil or anti-freeze). Take all

TLM readings when the fluid in the

tank is calm.

• The TLM is mounted next to the tank

wall or in a corner.

• If there is any structural bracings or

obstructions between the TLM and

the surface of the fluid in the tank.

FIG. 5

TLM must be mounted within 2 degrees

from perpendicular to the surface of the

fluid.

Loading...

Loading...