Troubleshootin

g

Flow Meter

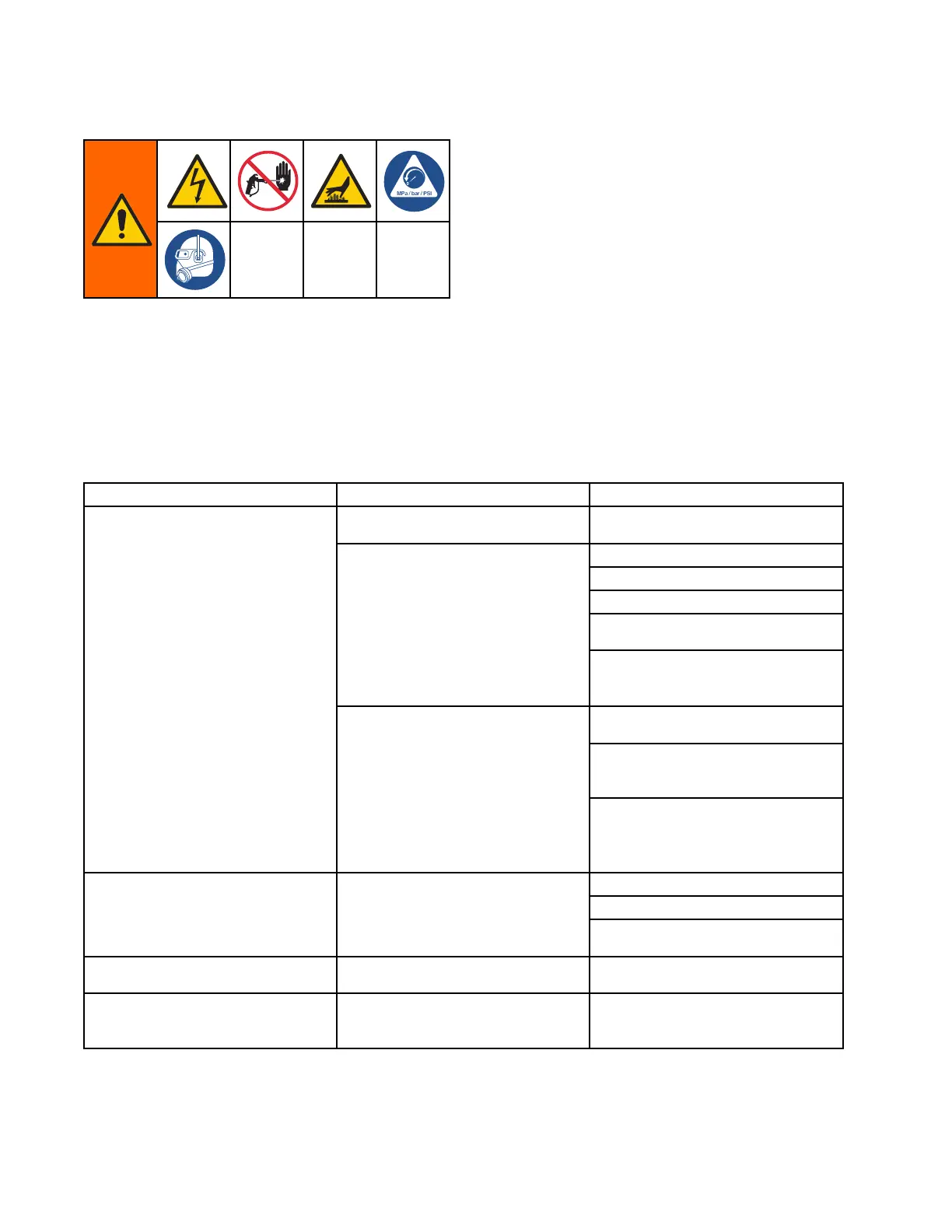

Before perfo

rming any troubleshooting procedures:

1. Relieve Pressure. See Pressure Relief Procedure, page 49.

2. Turn main power switch OFF.

3. Allow equipment to cool.

Problems

Try the rec

ommended solutions in the order given for each problem, to avoid unnecessary repairs.

Problem

Cause Solution

The k-factor entered in the ADM is

incorrect.

Update the k-factor. See

Replace Flow Meter, page 64.

Increase

the feed pump pressure.

Install

a larger feed pump.

Clean th

e y-strainer filter.

Install a smaller mix chamber in

the spray gun.

Cavitat

ion is reducing the pump

perform

ance.

Condition the material in the drums

to the ambient temperature of the

proportioner.

Re-route the feed hoses to a lower

height.

Purge air from the system. Refer

to your ratio monitor manual for

instructions.

The material ratio is significantly

offset from 1 : 1.

Air is trapped in the system,

between the feed pumps and the

heated hose.

Pla

ce the heated hose on flat

gro

und. Spray material into a

was

te container until all air has left

th

e system.

Increase the feed pump pressure.

Install a larger feed pump.

The ADM displays low inlet

pressure alarms, but the inlet

pressure reading appears correct..

While spraying, the inlet pressure

drops below 30 psi.

Install a smaller mix chamber in

the spray gun.

T

he material flow and ratio are not

displayed on the ADM.

T

he flow meter is disabled.

E

nable the flow meter on System

Screen 1.

The flow meter repeatedly disables

itself.

The inlet sensors are disabled. Enable the inlet sensors. Inlet

sensors must be enabled for the

flow meter to function.

48 333024N

Loading...

Loading...