Repair

Repair

Repairing th

is equipment requires access to parts

that may caus

e electric shock or other serious

injury if wor

k is not performed properly. Be sure to

shut off all p

ower to equipment before repairing.

Before Beginning Repair

NOTICE

Proper sys

tem setup, startup, and shutdown

procedure

s are critical to electrical equipment

reliabili

ty. The following procedures ensure steady

voltage. F

ailure to follow these procedures will

cause vol

tage fluctuations that can damage

electric

al equipment and void the warranty.

1. Flush if n

ecessary. See Flushing, page 52.

2. See Shutd

own, page 50.

Flush Inlet Strainer Screen

The inl

et strainers filter out particles that can plug the

pump in

let check valves. Inspect the screens daily as

part o

f the startup routine, and clean as required.

Isocyanate can crystallize from moisture

contamination or from freezing. If the chemicals used

are clean and proper storage, transfer, and operating

procedures are followed, there should be minimal

contamination of the A-side screen.

Note

Clea

n the A-side screen only during

dail

y startup. This minimizes moisture

con

tamination by immediately flushing

out

any isocyanate residue at the start of

dis

pensing operations.

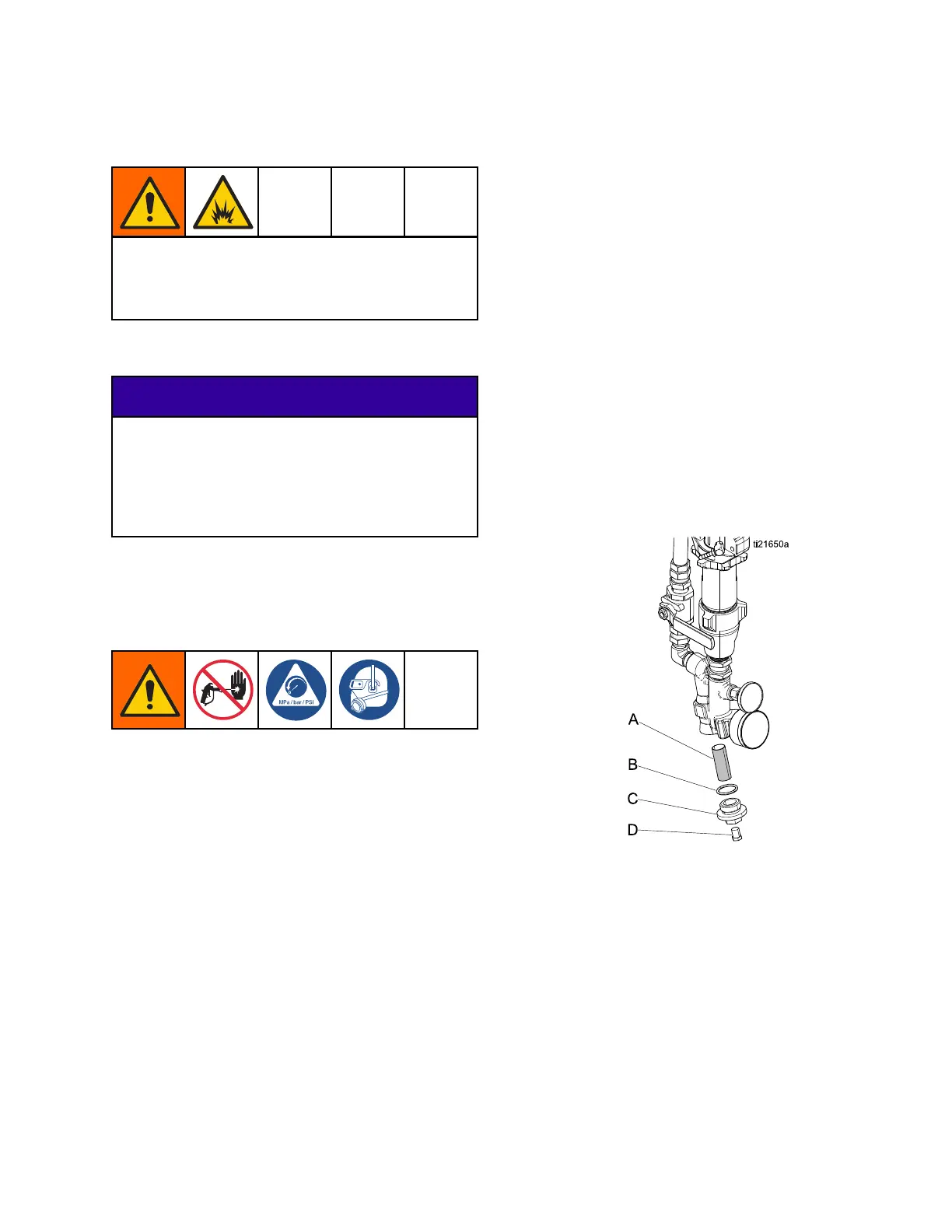

1. Close the fluid inlet valve on the y-strainer inlet

and shut off the appropriate feed pump. This

prevents material from being pumped while

cleaning the screen.

2. Place a container under the strainer base to catch

drain off when removing the strainer plug (C).

3. Remove the screen (A) from the strainer

manifold. Thoroughly flush the screen with

compatible solvent and shake it dry. Inspect the

screen. No more than 25% of the mesh should

be restricted. If more than 25% of the mesh is

blocked, replace the screen. Inspect the o—ring

(B) and replace as required.

4. Ensurethepipeplug(D)isscrewedintothe

strainer plug (C). Install the strainer plug with the

screen (A) and o—ring (B) in place and tighten.

Do not overtighten. Let the gasket make the seal.

5. Open the fluid inlet valve, ensure that there are

no leaks, and wipe the equipment clean. Proceed

with operation.

333024N 53

Loading...

Loading...