6 307273

Maintenance

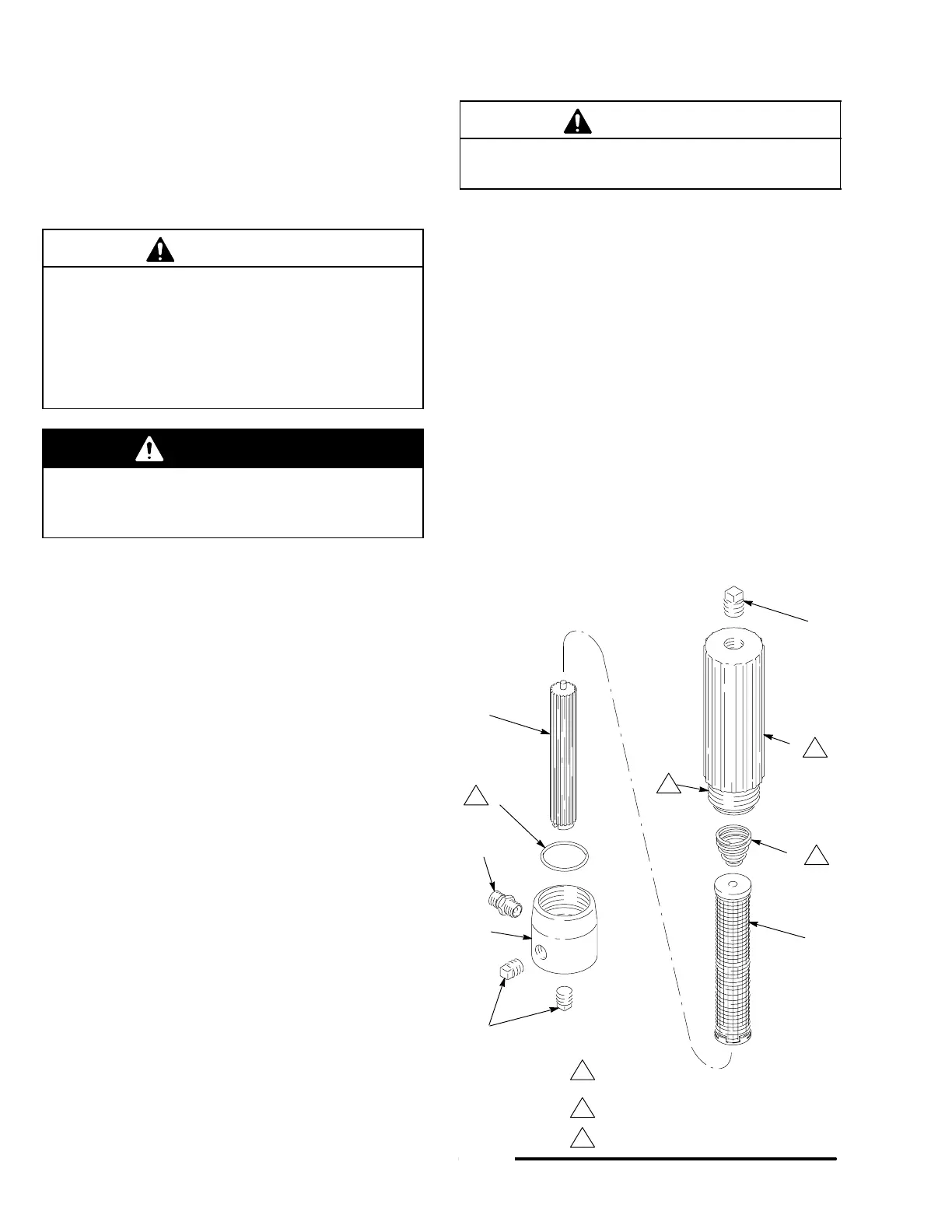

Cleaning the Filter

Dried paint sediment can clog the filter screen and

greatly reduce filtering ability. Dried paint also makes

the filter difficult to remove. Clean the filter regularly;

daily if needed, following the procedure below.

CAUTION

To avoid damaging parts, never force them apart. If

any parts are stuck tightly together, soak them in a

compatible solvent before disassembling them.

Be careful not to drop or damage the filter housing

and bowl. Dirt, paint sediment, nicks or scratches

may prevent the o-ring (3) from seating properly.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 5.

1. Relieve the pressure.

2. Carefully remove the drain plug (1) from the bot-

tom of the filter bowl (7) to drain the fluid.

NOTES:

D Some models are supplied with a drain valve

(12). Refer to the parts list for your model.

D Drain plug not used with Model 241107.

3. Unscrew the bowl from the filter housing (9).

4. Pull the screen (5) straight out of the bowl. (See

Accessories for other available screens.)

5. Remove the compression spring (8) from the filter

bowl (7).

6. To remove the filter support (6), gently push in on

the filter support stud. Replace the filter support if

the ridges are worn.

7. Clean all parts thoroughly with a compatible sol-

vent.

8. Place the filter support (6) in the screen (5) so the

support stud fits through the small opening in the

bottom of the screen.

9. Press fit the compression spring (8) to the bottom

of the filter bowl (7).

10. Carefully install the filter support (6) and screen (5)

into the filter bowl (7).

CAUTION

Improper assembly of the filter support, screen and

spring will prevent filtering and damage parts.

11. Replace the o-ring (3) if damaged or worn. Lubri-

cate the o-ring with No. 2 grease. Bend it into a

kidney shape, then carefully push it into the groove

to avoid damaging it.

12. Lubricate the filter bowl (7) threads and screw it

firmly into the housing (9).

NOTE: Be sure the bottom drain plug or drain valve is

closed before starting the pump.

Model 214570, 236789: Apply PTFE tape to all non-

swiveling pipe threads.

All other models: Apply anaerobic pipe sealant to all

non-swiveling pipe threads.

Fig. 2

1

3

2

Lubricate

Press fit spring to bottom of bowl

Screw bowl firmly into housing

NOTES:

0252

1

7

8

5

6

3

2

9

4

3

2

1

1

Model 214570 is shown

Loading...

Loading...