Pressure Control Adjustment

USE EXTREME CAUTION WHEN PERFORMING

THIS ADJUSTMENT PROCEDURE to reduce the

risk of a fluid injection injury or other serious bodily

injury which can result from component rupture,

electric shock, fire, explosion, or moving parts.

.“.

This procedure sets the sprayer

195

bar MAXIMUM

WORKING PRESSURE and sets the overpressuriza-

tion switch (microswitch) to approximately 3600 psi

(242

bar).

Perform this procedure whenever the pressure con-

trol assembly is removed and reinstalled or re-

~

placed, or a new circuit board

is

installed.

.I...”

Improper adjustment can cause the sprayer to over-

explosion. It may also prevent the sprayer from

ob-

pressurize and result in component rupture, fire or

taining the maximum working pressure, resulting in

poor sprayer performance.

ing pressure of

195

bar by performing these adjust-

NEVER try to increase the sprayer’s maximum work-

ments in any other way. Normal operation

of

the

sprayer at higher pressures may result in compo-

justment, however, the sprayer pressure must be

nent rupture, fire or explosion. To perform this ad-

femporari/y increased above the normal working

pressure.

Use a

new

15.2

m spray hose rated for at least

195

bar MAXIMUM WORKING PRESSURE.

A

used, un-

der-rated hose could develop a high pressure leak

or rupture.

NOTE: The following tools and equipment are re-

4.

Place the pump suction tube in a pail of clean

quired for this procedure.

water.

3/8 in. nut driver or 3/6 in. socket wrench

114

in. open end wrench

7/16

in:open end wrench

0

-

350 psi, oil-filled

test

gauge,

Part

No.

102-814

Paii of clean water

Mineral spirits

NEW

high pressure spray hose, Part No.

214-915

5.

Be sure the gun safety latch

is

engaged.

1.

Follow the Pressure

Relief

Procedure

Warning

on page

2.

2.

Refer to the above list

of

tools and equipment

filter and install the fluid-filled pressure gauge

(A)

needed. Remove the plug from the top

of

the fluid

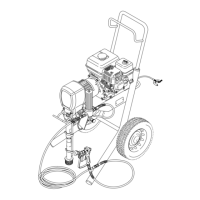

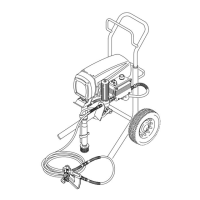

Refer to Fig.

21.

Connect the gun to the new test

hose and connect the hose to the sprayer outlet.

3. Remove the pressure control cover.

Fig.

21

26 307-889

Loading...

Loading...