21

Never make adjustments with the en-

gine running.

LOSS OF POWER IN THE H

2

DRIVE SYSTEM

Check the fl uid level and make sure the proper

amount of fl uid is in the reservoir. The cooling

fi ns and fan blades should be clean and free of

foreign matter.

NO POSITIVE NEUTRAL

POSITION

If drive wheels travel forward or backward when

the steering lever is in swing-out position (neu-

tral), adjustment is required.

NEUTRAL ADJUSTMENT

(Refer to illustration page 35)

1. Block up under tractor frame so both drive

wheels are off the ground.

2. Make sure parking brake is released.

3. Remove linkage rod (item 6) from hydro

pump control arm (item 3).

4. Place steering levers in the neutral swing-out

position and start engine.

5. If either of the drive wheels turn, proceed

with the following adjustment.

6. Loosen locking nut (item 13) and rotate piv-

ot bolt (item 11) until neutral is achieved.

Tighten locking nut.

NOTE: Pivot bolt roller is mounted off center

and works as an eccentric when the bolt is

turned.

7. Repeat procedure for drive system on the

other side.

8. Reinstall linkage rod in control arm. If ball

stud does not reinstall into control arm with-

out moving the control arm, adjust length

of linkage rod until it does to assure neutral

adjustment will be maintained when linkage

is connected.

9. Test drive machine for straight line travel

with both levers full forward. If travel is

not in a straight line, adjust the steering le-

ver stop on the side that is the fastest, i.e.,

if machine goes to the left, adjust the right

steering stop to slow down the right drive

system until travel is straight ahead.

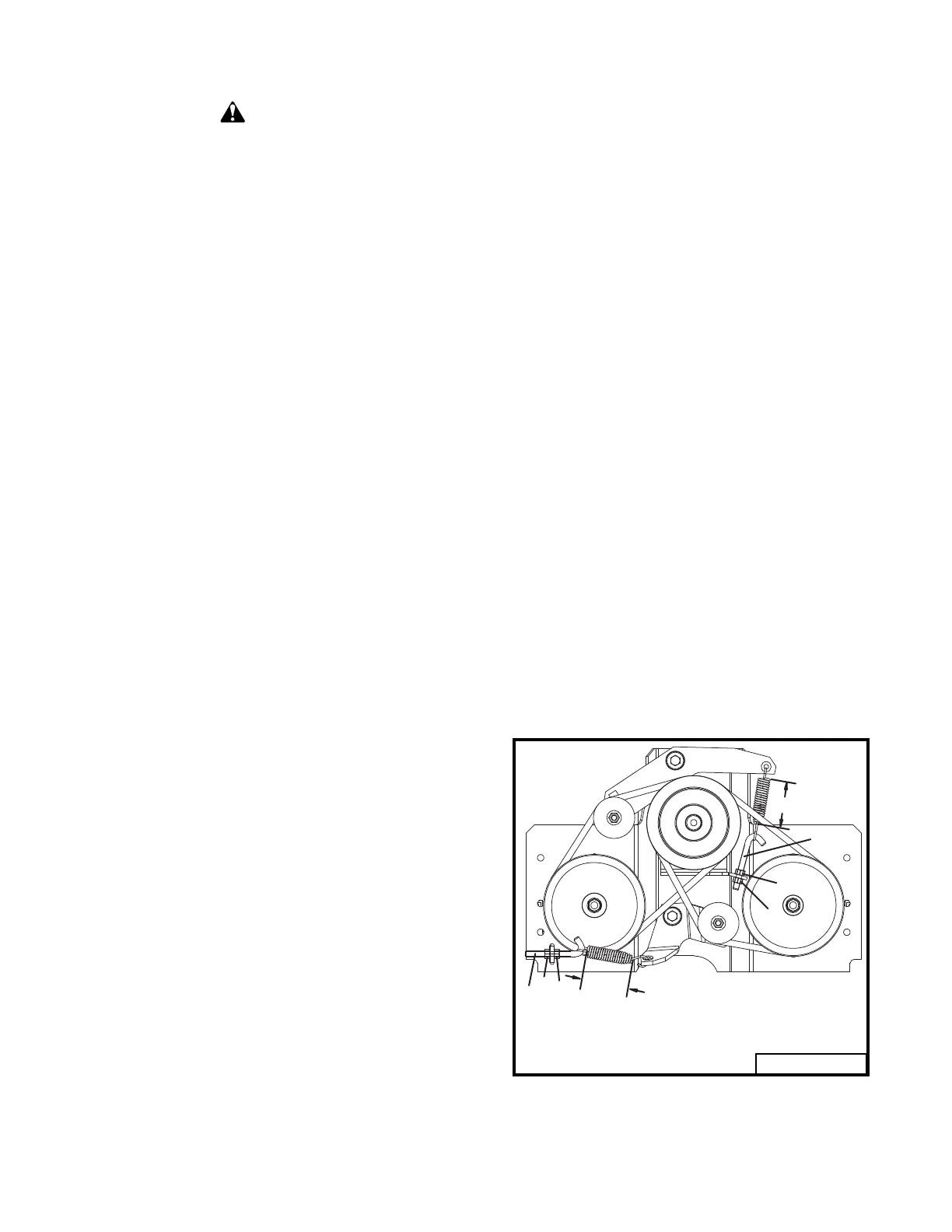

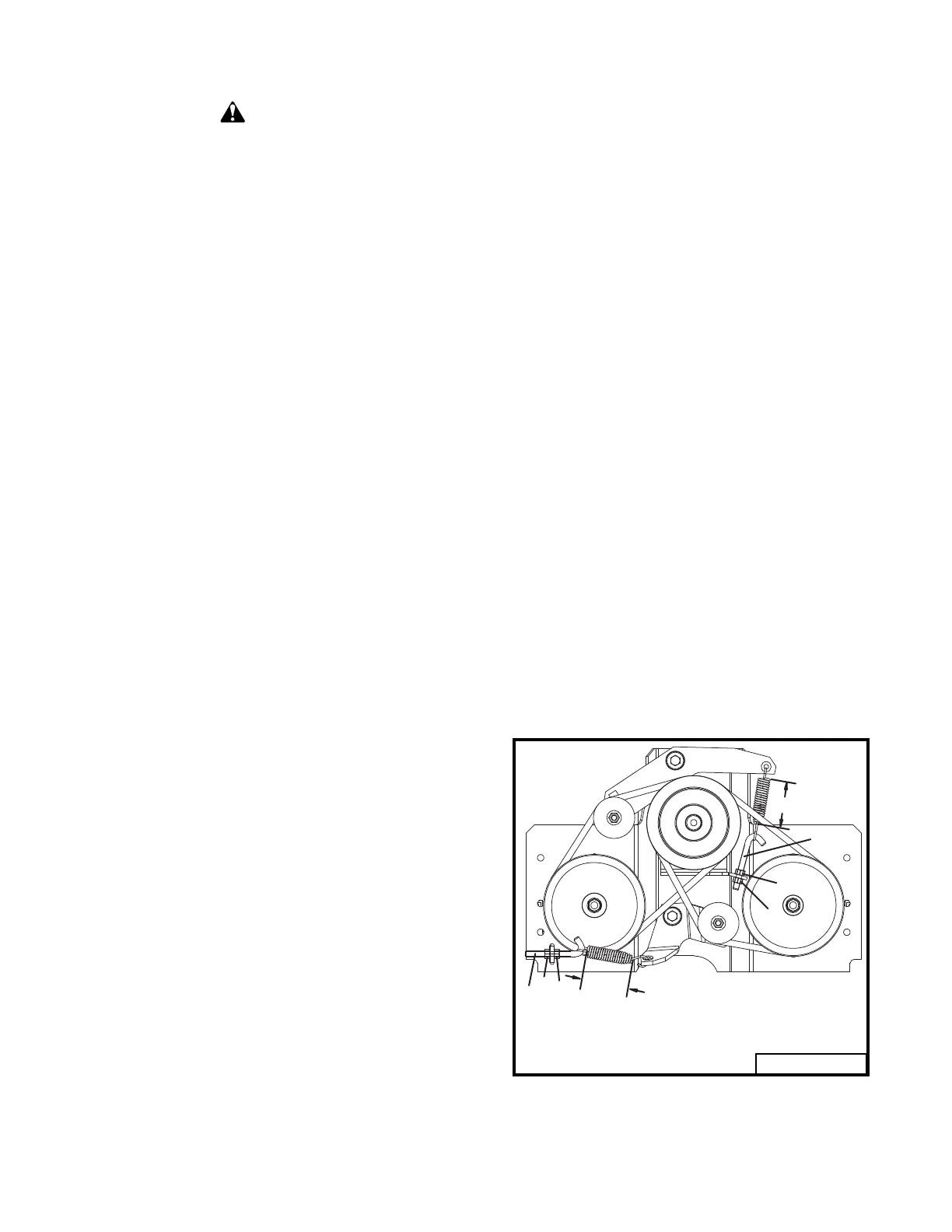

H

2

BELT REPLACEMENT

(Refer to illustration page 33)

1. Remove key from ignition switch.

2. Loosen the belt tension by loosening idler

adjustment J-bolts (item 47) and remove

belts from pulleys.

3. Remove two bolts (item 36) between fl ex

coupling disc (item 27) and drive sheave

(item 19). Remove the two spacers (item

26) between fl ex coupling and drive sheave.

4. Remove the two belts through the gap cre-

ated by the removal of the two spacers.

5. Replace belts and reverse procedure to in-

stall belts.

NOTE: Upon reassembly, install fl at washers

(item 33) with rounded edges in contact with

fl ex coupling disc. On opposite side of disc in-

stall spacers (item 26) with chamfered edges

in contact with fl ex coupling disc.

6. To adjust the belt tension, loosen the top

jam nut (item 2, Fig 6) on the J-bolt. Ad-

just the lower jam nut (item 3, Fig 6) so that

the spring coils are extended to a length of

2.75". Tighten the top jam nut against the

bracket.

7. Recheck spring tension length after unit has

run for ten (10) hours.

ADJUSTMENTS AND TROUBLESHOOTING

CAUTION

1

2

3

1

2

3

2.75"

2.75"

1. Idler Adjustment J-Bolt

2. Top Jam Nut

3. Lower Jam Nut

97068A

Fig. 6

Loading...

Loading...