Do you have a question about the GRAVOGRAPH IS400 and is the answer not in the manual?

Details EC marking and EEC directives for machine compliance.

Covers conformity to safety norms and fuse compliance for input/output.

States conformity to EN ISO12100-1 and EN ISO12100-2 standards.

Lists EMC norms like EN 55022 and EN 61000 for emissions and immunity.

Emphasizes class 1 connection to a neutral socket and electrician installation.

Lists restrictions and warnings for using the IS400 machine.

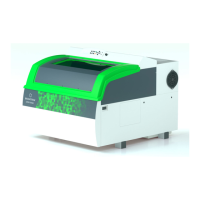

Identifies components of the IS400 machine's front panel and main body.

Explains how to use the vice to hold the material for engraving.

Shows the application of the long plate support kit.

Details the ports and connectors on the back of the IS400 machine.

Guidelines for placing the machine on a stable surface and ensuring ventilation.

Recommendations for connecting the machine to the power supply and avoiding interference.

Step-by-step guide for connecting control panel, electronics box, and power cable.

Instructions for connecting the IS400 machine to a PC via USB or parallel ports.

Procedures for switching the machine on, off, and handling potential issues.

Steps for setting the machine's language and verifying its model.

Guide for installing the engraving software on a Windows XP computer.

How to correctly place and secure the material to be engraved in the vice.

Using the software feature to define the engraving area with the machine.

Procedure for sending engraving designs from software to the IS400 machine.

Steps for setting up, adjusting pressure, and positioning the spindle.

Instructions on how to properly insert and secure the engraving cutter.

Setting the spindle's starting position and adjusting the engraving depth.

How to set the appropriate rotation speed for the spindle.

Procedures and safety precautions before starting the engraving operation.

Step-by-step guide on how to replace the belt in the tool-holder.

Procedure for recalibrating the machine's reference points and Z mechanical stop.

Details the physical dimensions and specifications of the machine and its components.

Specifies sound emission levels according to ISO 11201.

Defines operational and storage temperature and humidity ranges.

Describes the laser diode used in the Point & Shoot function.

Lists power supply, current, frequency, output, and protection details.

Details specifications for the spindle and displacement motors.

Lists available connection types like Parallel, USB, and memory card.

Specifies the operating system compatibility for the GravoStyle software.

Specifications and details for the pen attachment accessory.

Specifications and details for the cylinder attachment accessory.

Specifications and details for the vacuum table accessory.

Specifications and details for the T-slot table accessory.

Lists available spindle types like Collet, Diamond, and Rotring.

| Technology | Rotary Engraving |

|---|---|

| Software | Gravostyle |

| Materials | Metals, plastics |

| Applications | Signage, Trophies |

| Power Supply | 100-240 V, 50/60 Hz |

Loading...

Loading...