Greenlee Textron / Subsidiary of Textron Inc.

11

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

853 Quad Bender™

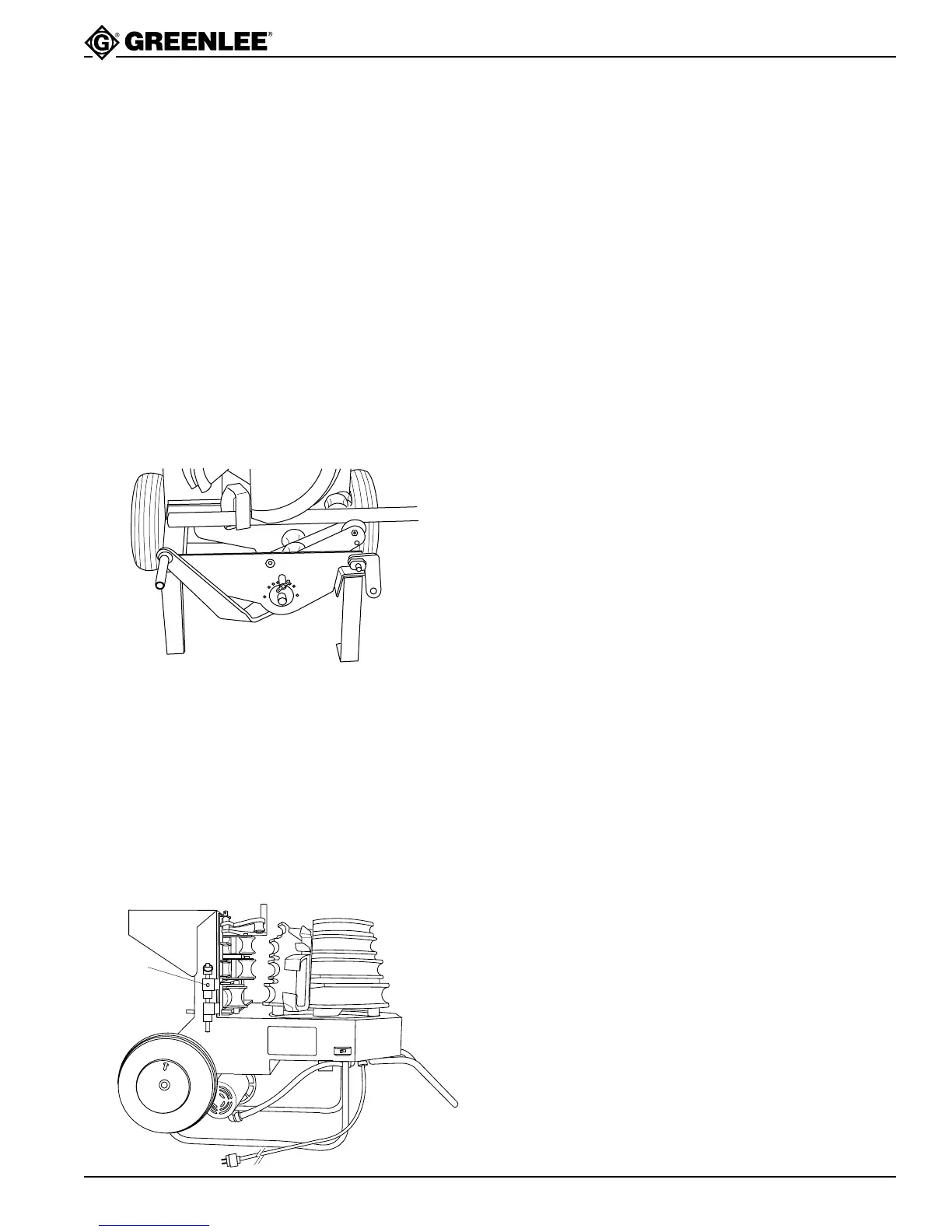

ADJUSTING THE SQUEEZE

When bending 1-1/4" to 2" EMT, IMC and rigid alumi-

num conduit, the roller support must be engaged so that

it contacts the conduit; the pressure against the conduit

is the “squeeze.” Typically, the squeeze adjustment arm

is vertical (at middle hole) but can be changed by

moving the position of the thumbscrew.

Due to variations in conduit, the standard adjustment

may provide too much or too little squeeze. If the

conduit develops excessive side marking when bent,

the squeeze is set too high; decrease squeeze one

position (hole) clockwise. If the conduit becomes

excessively oval or wrinkled, the squeeze is set too low;

increase squeeze position (hole) counterclockwise.

When bending 1-1/4" to 2" aluminum rigid conduit,

decrease the squeeze by three settings.

Adjusting the Squeeze

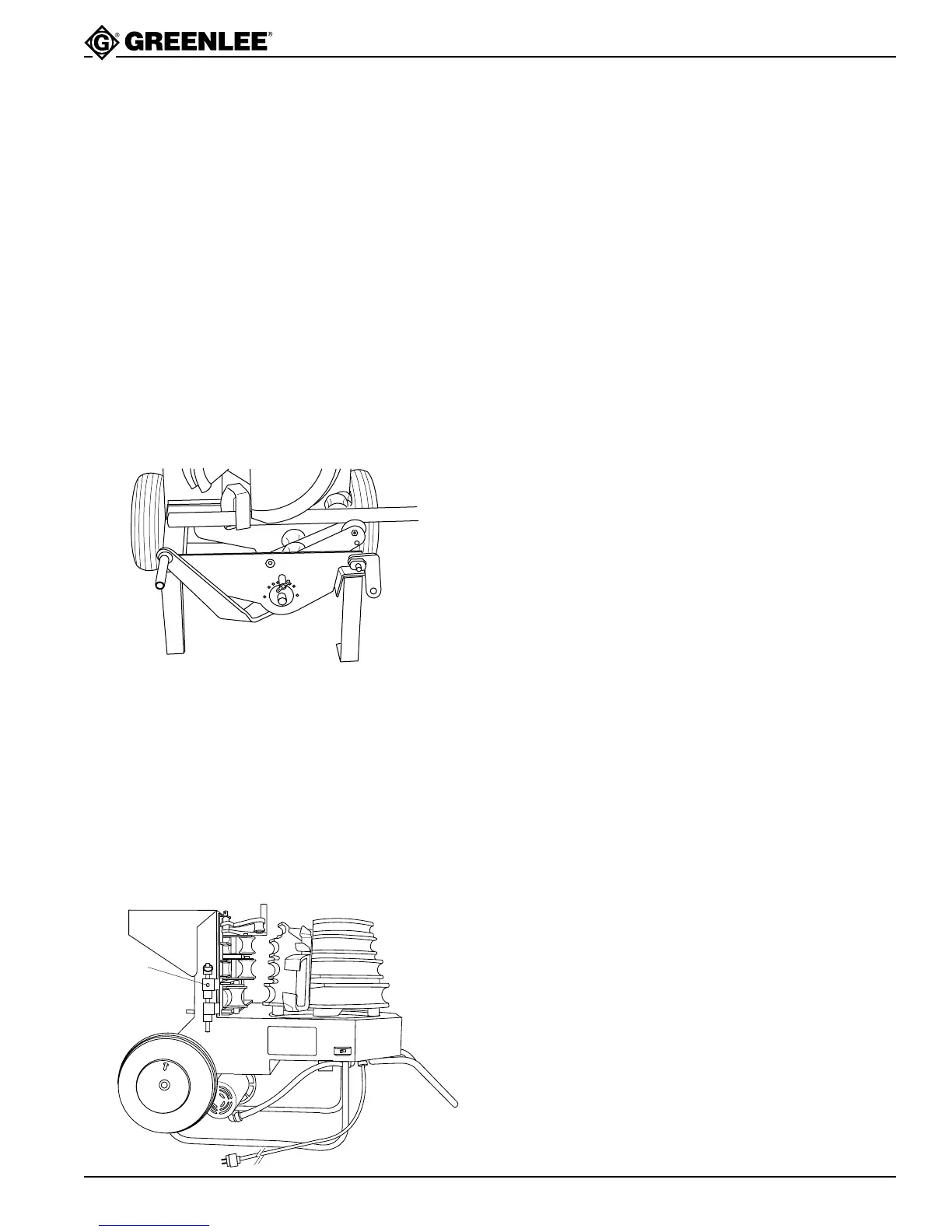

ADJUSTING THE ROLLER SUPPORT ASSEMBLY

LOCATION

If the conduit develops excessive side marking when

bending in the horizontal position, the location of the

roller support assembly might need adjusting. Loosen

the left-hand and right-hand locator screws for the

Roller Support Assembly (see p. 6) to align the center-

line of the roller with the centerline of the shoe groove.

Retighten the locator screws.

R.H.

Locator

Screw

Adjusting the Roller Support Location

Operation (cont’d)

Loading...

Loading...