27

English (US)

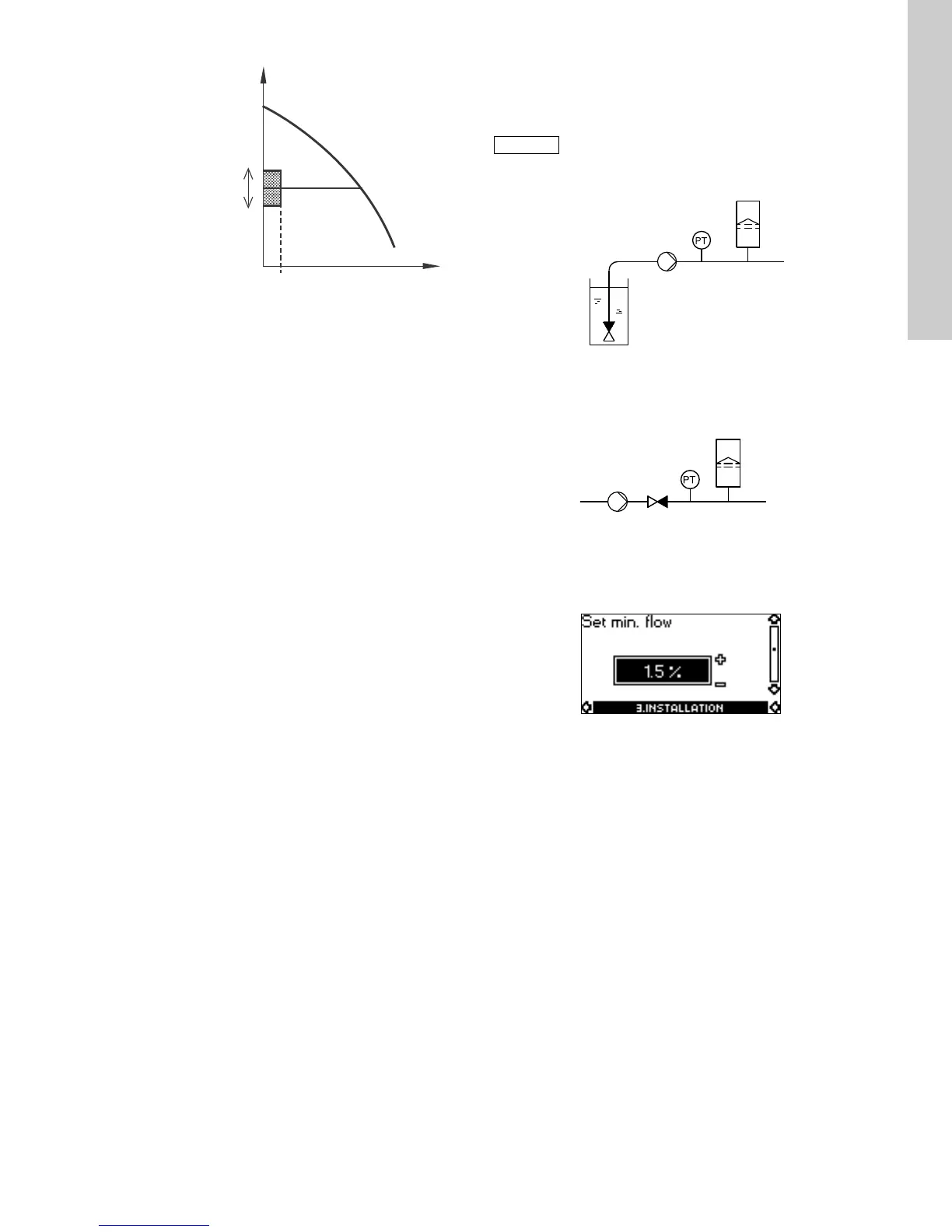

Fig. 31 Difference between start and stop pressures (∆H) and

minimum flow (Q

min

)

In start/stop operation, the pressure will vary between the start

and stop pressures. See fig. 31.

In "User-defined" mode, ∆H has been factory-set to 10 % of the

actual setpoint. ∆H can be set within the range from 5 to 30 % of

actual setpoint.

The pump will change to start/stop operation if the flow becomes

lower than Q

min

.

Q

min

is set in % of the rated flow of the pump (see pump

nameplate).

In "User-defined" mode, Q

min

has been factory-set to 10 % of

rated flow.

Low-flow detection

Low flow can be detected in two ways:

1. A built-in "low-flow detection function" which is active if none

of the digital inputs are set up for flow switch.

2. A flow switch connected to one of the digital inputs.

1. Low-flow detection function:

The pump will check the flow regularly by reducing the speed

for a short time. If there is no or only a small change in

pressure, this means that there is low flow. The speed will be

increased until the stop pressure (actual setpoint + 0.5 x ΔH)

is reached and the pump will stop. When the pressure has

fallen to the start pressure (actual setpoint - 0.5 x ΔH), the

pump will restart.

– If the flow is higher than the set minimum flow (Q

min

), the

pump will return to continuous operation at constant

pressure.

– If the flow is still lower than the set minimum flow (Q

min

), the

pump will continue in start/stop operation until the flow is

higher than the set minimum flow (Q

min

). When the flow is

higher than the set minimum flow (Q

min

), the pump will

return to continuous operation.

2. Flow switch:

When the digital input is activated for more than 5 seconds

because there is low flow, the speed will be increased until the

stop pressure (actual setpoint + 0.5 x ΔH) is reached, and the

pump will stop. When the pressure has fallen to start

pressure, the pump will restart. If there is still no flow, the

pump will quickly reach the stop pressure and stop. If there is

flow, the pump will continue operating according to the

setpoint.

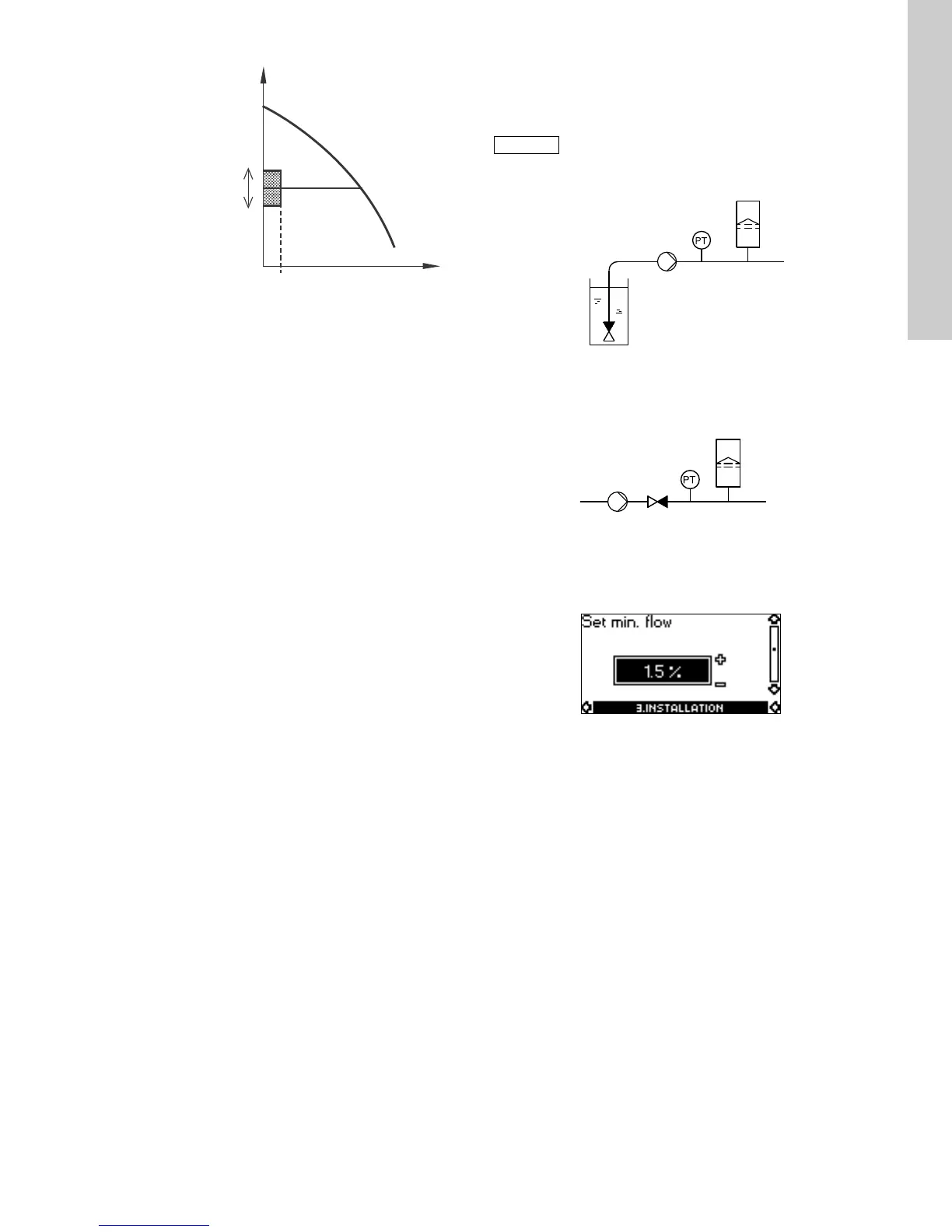

Operating conditions for the low-flow stop function

It is only possible to use the stop function if the system

incorporates a pressure sensor, a non-return valve and a

diaphragm tank.

Fig. 32 Position of the non-return valve and pressure sensor in

system with suction lift operation

Fig. 33 Position of the non-return valve and pressure sensor in

system with a positive inlet pressure

Set min. flow

Set the minimum flow (Q

min

) in this display. This setting

determines at which flow rate the system is to change from

continuous operation at constant pressure to start/stop operation.

The setting range is 5 to 30 % of rated flow.

Factory setting: 10 %.

TM05 6079 4512

Stop pressure

Start pressure

The non-return valve must always be installed

before the pressure sensor. See figs 32 and 33.

TM03 8582 1907TM03 8583 1907

Pressure sensor

Diaphragm tank

Non-return

valve

Pump

Diaphragm tank

Pressure sensor

Pump Non-return valve

Loading...

Loading...