5.4.8 Stop function

The stop function can be set to these values:

• Active

• Not active.

When the stop function is active, the pump will be stopped at very

low flows. The controller will stop the pump to protect the pump as

follows:

• avoid unnecessary heating of the pumped liquid

• reduce wear of the shaft seals

• reduce noise from operation.

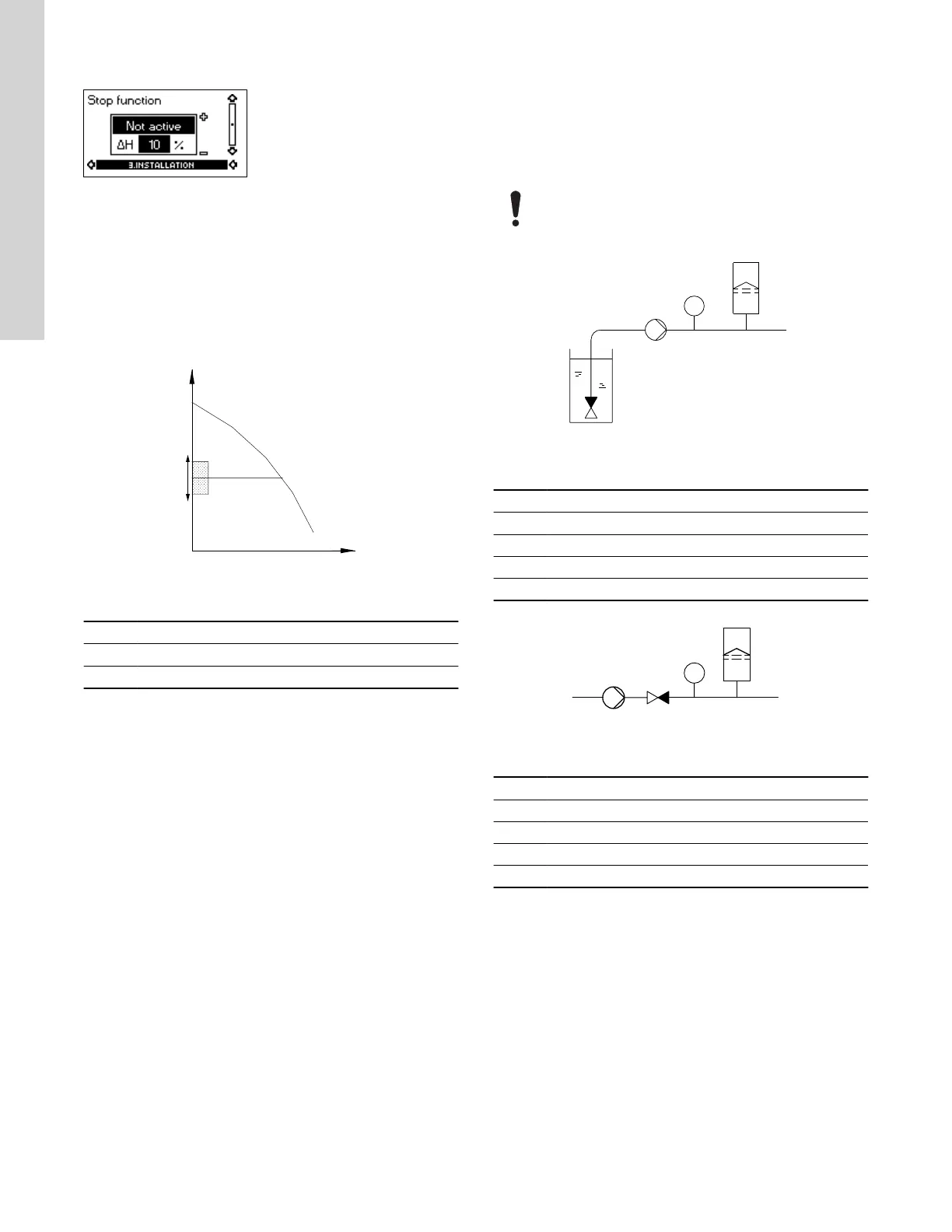

TM007744

Difference between start and stop pressures (ΔH)

Pos. Description

1 Stop pressure

2 Start pressure

ΔH is factory-set to 10 % of actual setpoint.

ΔH can be set within the range from 5 % to 30 % of actual setpoint.

Low flow can be detected in two different ways:

1. A built-in "low-flow detection function" which functions if the

digital input is not set up for flow switch.

2. A flow switch connected to the digital input.

1. Low-flow detection function

The pump will check the flow regularly by reducing the speed for a

short time. If there is no or only a small change in pressure, this

means that there is low flow. The speed will be increased until the

stop pressure (actual setpoint + 0.5 x ΔH) is reached and the pump

will stop. When the pressure has fallen to the start pressure (actual

setpoint - 0.5 x ΔH), the pump will restart.

When restarting, the pumps will react differently according to pump

type:

Three-phase pumps

1. If the flow is higher than the low-flow limit, the pump will return

to continuous operation at constant pressure.

2. If the flow is still lower than the low-flow limit, the pump will

continue in start/stop operation. It will continue in start/stop

operation until the flow is higher than the low-flow limit; when

the flow is higher than the low-flow limit, the pump will return to

continuous operation.

2. Flow switch

When the digital input is activated for more than 5 seconds because

there is low flow, the speed will be increased until the stop pressure

(actual setpoint + 0.5 x ΔH) is reached, and the pump will stop.

When the pressure has fallen to start pressure, the pump will start

again. If there is still no flow, the pump will quickly reach stop

pressure and stop. If there is flow, the pump will continue operating

according to the setpoint.

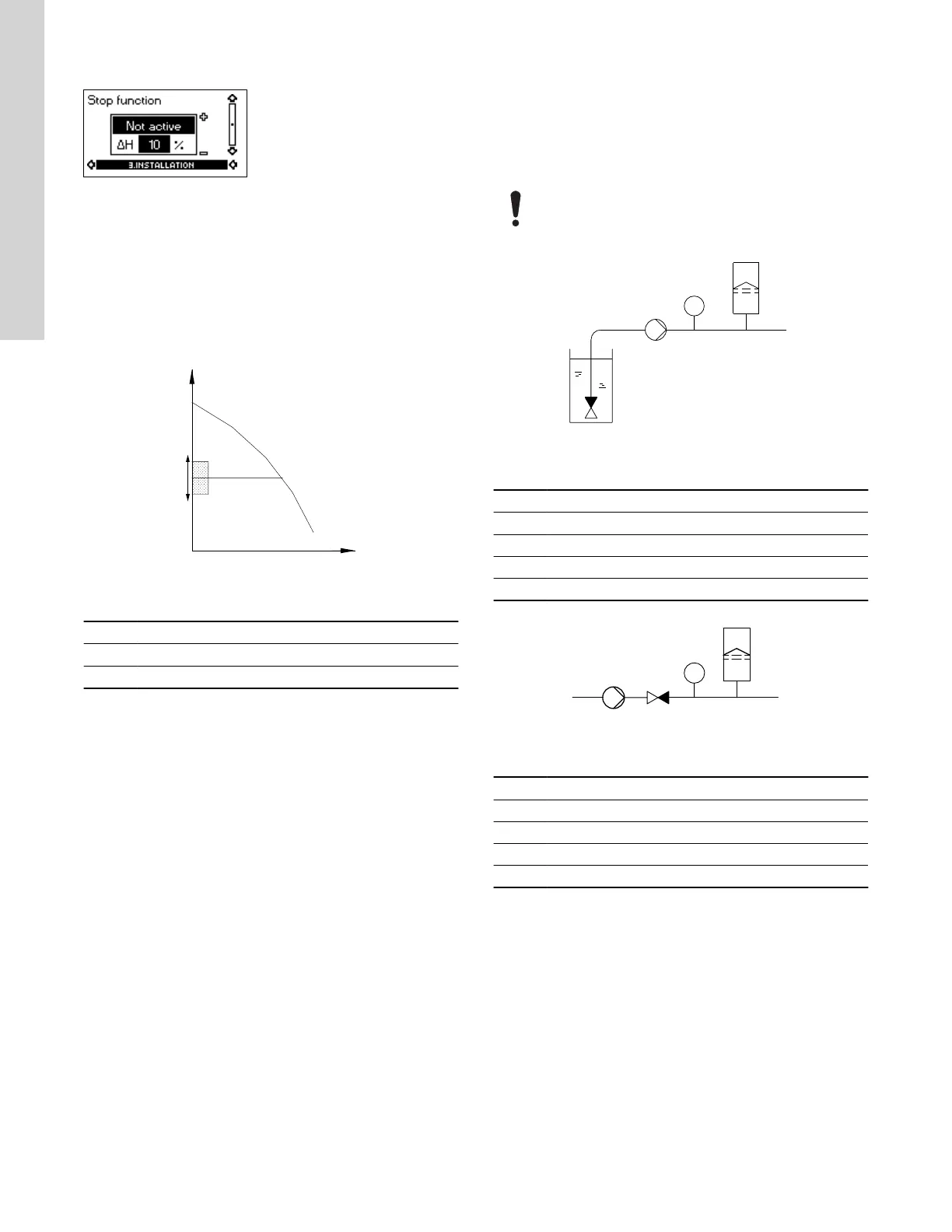

Operating conditions for the stop function

It is only possible to use the stop function if the system incorporates

a pressure sensor, a non-return valve and a diaphragm tank.

The non-return valve must always be installed before the

pressure sensor. See the figures below.

TM081973

Position of the non-return valve and pressure sensor in system

with suction lift operation

Pos. Description

1 Non-return valve

2 Pump

3 Pressure sensor

4 Diaphragm tank

TM038583

Position of the non-return valve and pressure sensor in system

with positive inlet pressure

Pos. Description

1 Pump

2 Non-return valve

3 Pressure sensor

4 Diaphragm tank

Diaphragm tank

The stop function requires a diaphragm tank of a certain minimum

size. The tank must be installed immediately after the pump and the

precharge pressure must be 0.7 x actual setpoint.

Recommended diaphragm tank size:

18

English (US)

Loading...

Loading...