Pos. Description

1 Digital input 2

2 Start/stop

3 GND (frame)

4 Setpoint input

5 +10 V

6 GND (frame)

7 Sensor input

8 +24 V

9 GND (frame)

10 Digital input 3

11 Digital input 4

12 Analog output

13 GND

14 Sensor input 2

15 +24 V

16 GND (frame)

17 PT 100 A

18 PT 100 A

19 PT 100 B

20 PT 100 B

G1 Group 1

G2 Group 2

G3 Group 3

A RS-485A

B RS-485B

Y Screen

A galvanic separation must fulfill the requirements for reinforced

insulation including creepage distances and clearances specified in

EN 61800-5-1.

4.4.10

Signal cables

• Use screened cables with a conductor cross-section of min. 28

AWG and max. 16 AWG for external on/off switch, digital input

and setpoint signals.

• Connect the screens of the cables to frame at both ends with

good frame connection. The screens must be as close as

possible to the terminals. See the figure below.

TM021325

Stripped cable with screen and wire connection

• Always tighten screws for frame connections whether a cable is

fitted or not.

• Make the wires in the pump terminal box as short as possible.

4.5

E-pump electrical connections

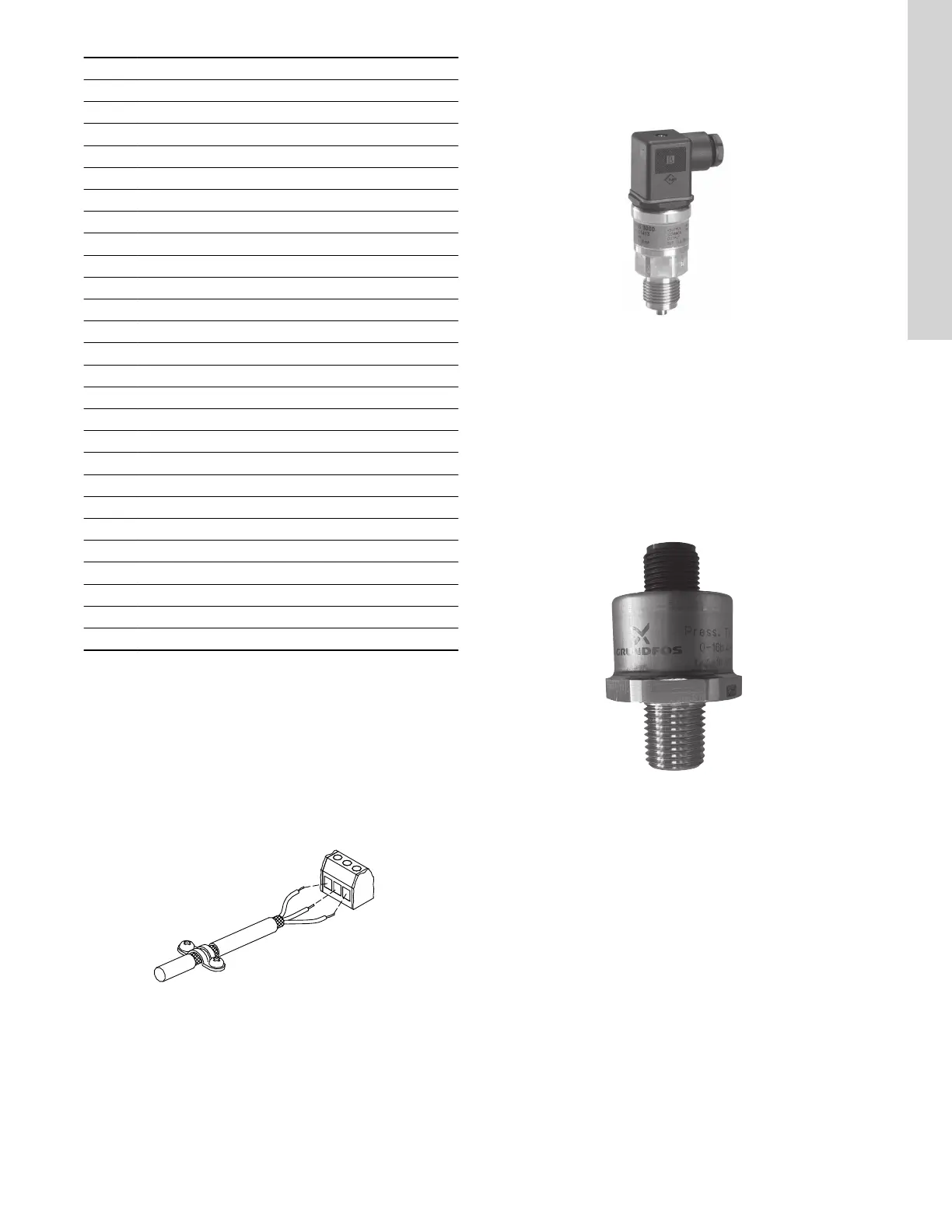

4.5.1 Connection of Danfoss pressure sensor MBS3000 to E-

pump

TM051533

Danfoss pressure sensor

Use screened cables with a cross-sectional area of minimum 28

AWG and maximum 16 AWG.

The blue wire of the pressure sensor is connected to the #7

terminal of the E-pump. The brown wire of the pressure sensor is

connected to the #8 terminal of the E-pump.

Related information

4.4.10 Signal cables

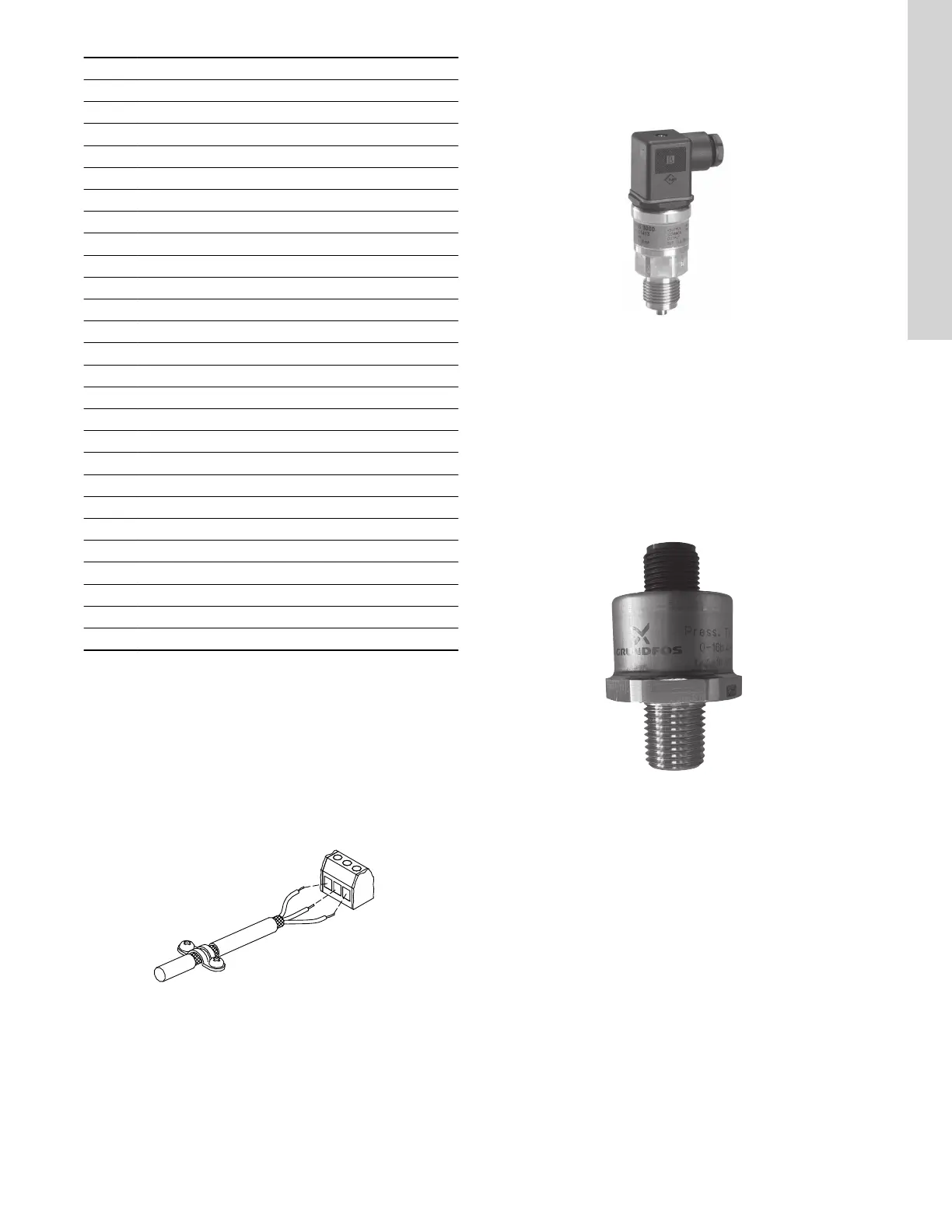

4.5.2

Connection of Grundfos pressure sensor ISP44 to E-

pump

TM083396

ISP44 pressure sensor

Use unscreened cables with a cross-sectional area of minimum 28

AWG and maximum 16 AWG.

The blue wire of the pressure sensor is connected to the #7

terminal of the E-pump. The brown wire of the pressure sensor is

connected to the #8 terminal of the E-pump.

9

English (US)

Loading...

Loading...