English (GB)

18

8.1 Sensors

The SE/SL pumps, 9-30 kW, can be equipped with a variety of

sensors for protection. The sensor specification table shows

which sensor types can be used for which pump types.

The wiring diagrams of the various types of sensor appear from

fig. 3 to fig. 8 in the appendix at the back of these installation and

operating instructions.

Sensor specification table

8.1.1 Thermal switches

Three bimetallic thermal switches (Klixon/PTC) are built into the

stator windings, and a contact will open in case of

overtemperature, i.e. 150 °C.

The supply voltage to the thermal switches must be 12-230 VAC.

The thermal switches are connected to the control cable, and

must be connected to the safety circuit of the separate pump

controller. See section 8. Electrical connection.

8.1.2 Moisture switches

Non-explosion-proof pumps have two moisture switches, which

are fitted in the upper and lower part of the motor compartment.

Moisture switches are motor protection devices which protect the

motor from damage due to moisture. The moisture switches are

non-reversing and must be replaced after they have been

released.

The moisture switches are connected to a separate circuit via the

control cable. See 8. Electrical connection. They must also be

connected to the safety circuit of the separate pump controller.

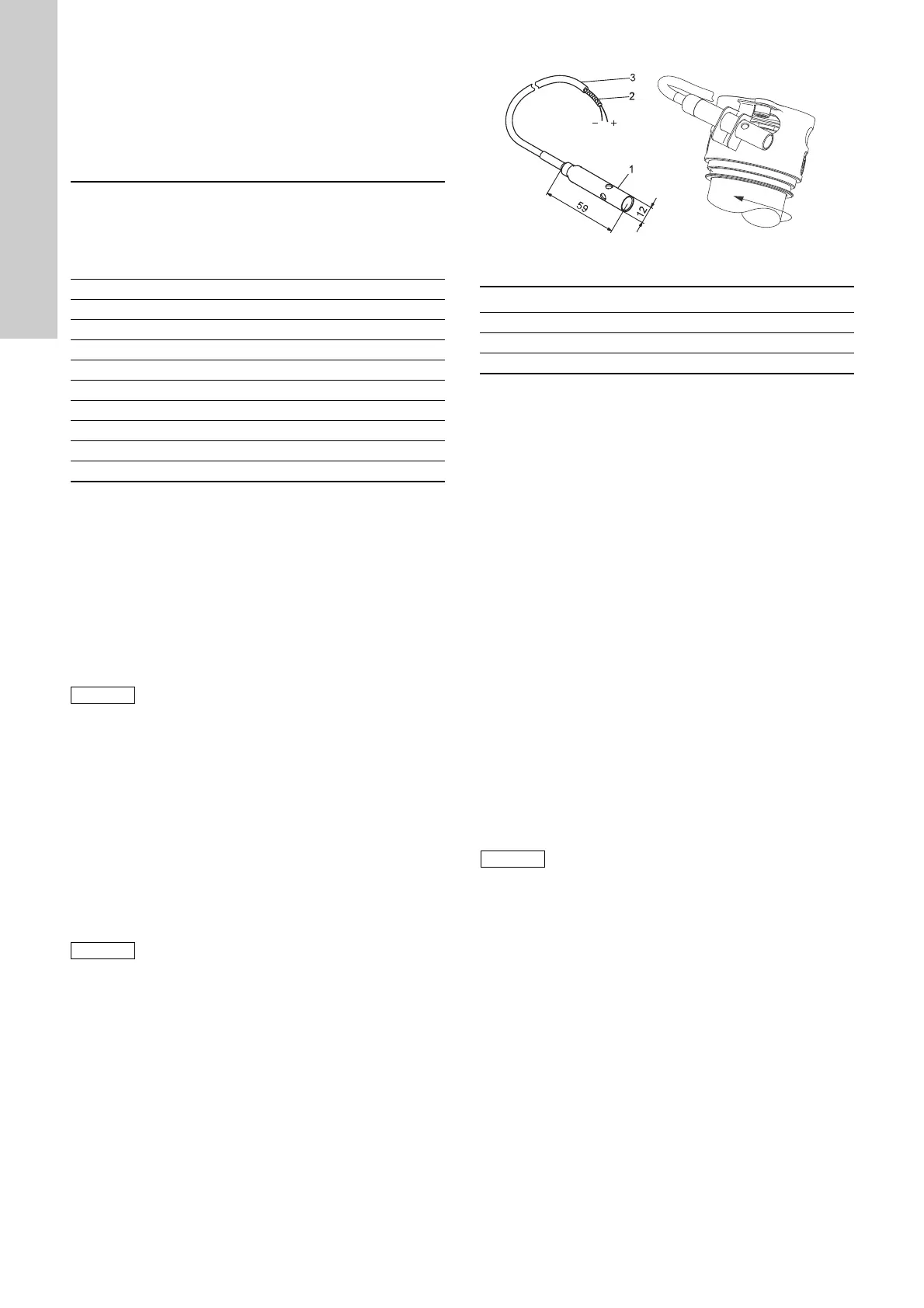

8.1.3 WIA sensor (water-in-air sensor)

The WIA sensor measures the water resistance and detects if

water is present. It also sends a signal if water is detected

(alarm). The sensor is fitted in a stainless steel tube for

mechanical protection.

Fig. 10 Water-in-air sensor

The sensor can be used together with Grundfos IO 113 or

SM 113, but it can also be used together with other controllers

with 4 to 20 mA inputs.

Together with IO 113, the sensor filters the signal and provides an

easy readout of the actual value. Furthermore, it is possible to set

a user-defined warning limit and calibrate the IO 113 and the

sensor to the motor liquid.

8.1.4 Thermistors

Thermistors are available as an accessory or as an FPV

(Factory Product Variant) option.

The thermistors can be used as motor protection devices to

monitor stator temperature instead of thermal switches and must

be connected to the thermistor relay in the control cabinet.

Checking after installation of pumps

1. Using a multimeter, check whether the circuit resistance is

< 150 Ω/thermistor.

2. Using a multimeter, check whether the insulation between

circuit and stator housing is outside the scale

(not measurable ).

3. Carry out a similar measurement at the end of the power

supply cable.

8.1.5 Pt1000 temperature sensor

The Pt1000 temperature sensor is available as an accessory or

as an FPV (Factory Product Variant) option.

The Pt1000 sensor is primarily used for the monitoring of bearing

temperature, but it can also be used in the stator.

The sensor resistance is

• 1000 Ω at 0 °C

• 1385 Ω at 100 °C

• approx. 1078 Ω at room temperature.

The temperature limits are:

• 90 °C: alarm for bearing temperature

• 130 °C: pump stop caused by high bearing temperature

• 150 °C: pump stop caused by high stator temperature.

Checking after installation of pump

1. Using a multimeter, check whether the resistance at room

temperature (20 °C) is approx. 1078 Ω.

2. Using a multimeter, check whether the insulation between

circuit and stator housing is outside the scale

(not measurable ).

3. Carry out similar measurements at the end of the power

supply cable.

During pump check, the Pt1000 sensor must be connected to a

recording device.

Standard pump

Sensor, pump

version 1

Sensor, pump

version 2

Klixon / PTC ●●●

Moisture switch, top ●●●

Moisture switch, bottom ●●●

WIA (water-in-air)

Pt1000 in stator winding ●●

Pt1000 in upper bearing ●

Pt1000 in lower bearing ●

PVS 3 vibration sensor ●

SM 113 ●

IO 113 ●

The motor-protective circuit breaker of the pump

controller must include a circuit which

automatically disconnects the power supply in

case the protective circuit for the pump is

opened.

The motor-protective circuit breaker of the pump

controller must include a circuit which

automatically disconnects the power supply in

case the protective circuit for the pump is

opened.

TM0 3 1164 1105 / TM0 3 1164 1105

Pos. Designation

1 Steel tube with sensor

2 Screen

3 Cable

The bearing temperature monitoring system is

only available as an accessory.

Loading...

Loading...