English (GB)

22

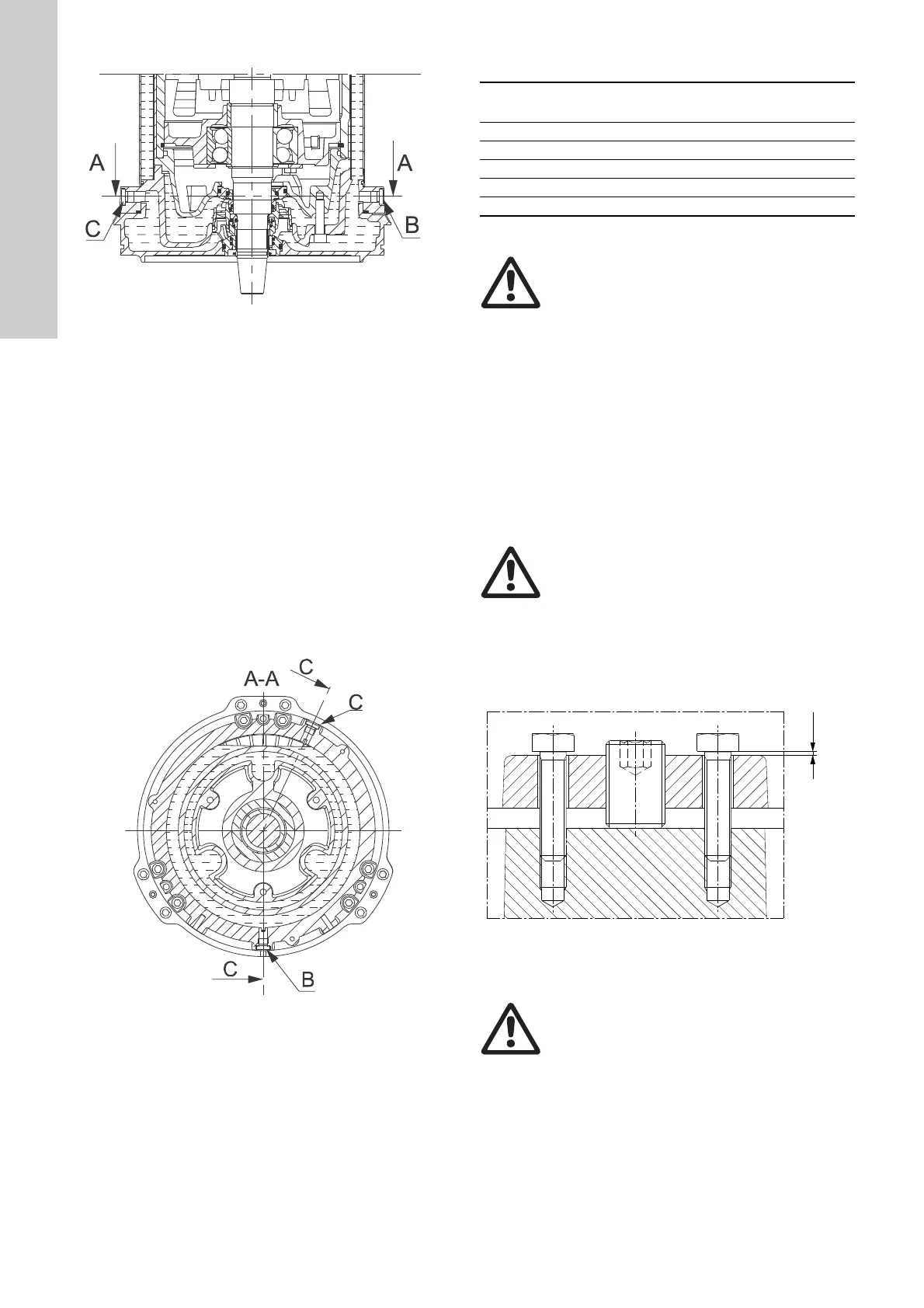

Fig. 14 SE pump, bottom view

Draining motor liquid, horizontal and vertical installation:

Place a container under the pump to collect all the drained-off

motor liquid; then place the pump in a horizontal position.

Remove screw B, fig. 15, which is facing downwards. Allow all

motor liquid to drain from the housing into the container. Replace

the O-ring with a new ring, insert screw B and tighten securely.

Filling motor liquid, vertical installation:

While the pump is standing vertically, fill the shaft seal housing

with motor liquid through hole A until the motor liquid reaches the

level indicated on fig. 13. Replace the O-rings with new rings,

insert the screws and tighten securely.

Filling motor liquid, horizontal installation:

Place the pump horizontally with plug B mounted and facing

downwards. Fill the shaft seal housing with motor liquid through

hole C until the motor liquid reaches the level indicated on fig. 15.

Replace the O-ring with a new ring, insert screw C and tighten

securely.

Fig. 15 SE pump, sectional horizontal view

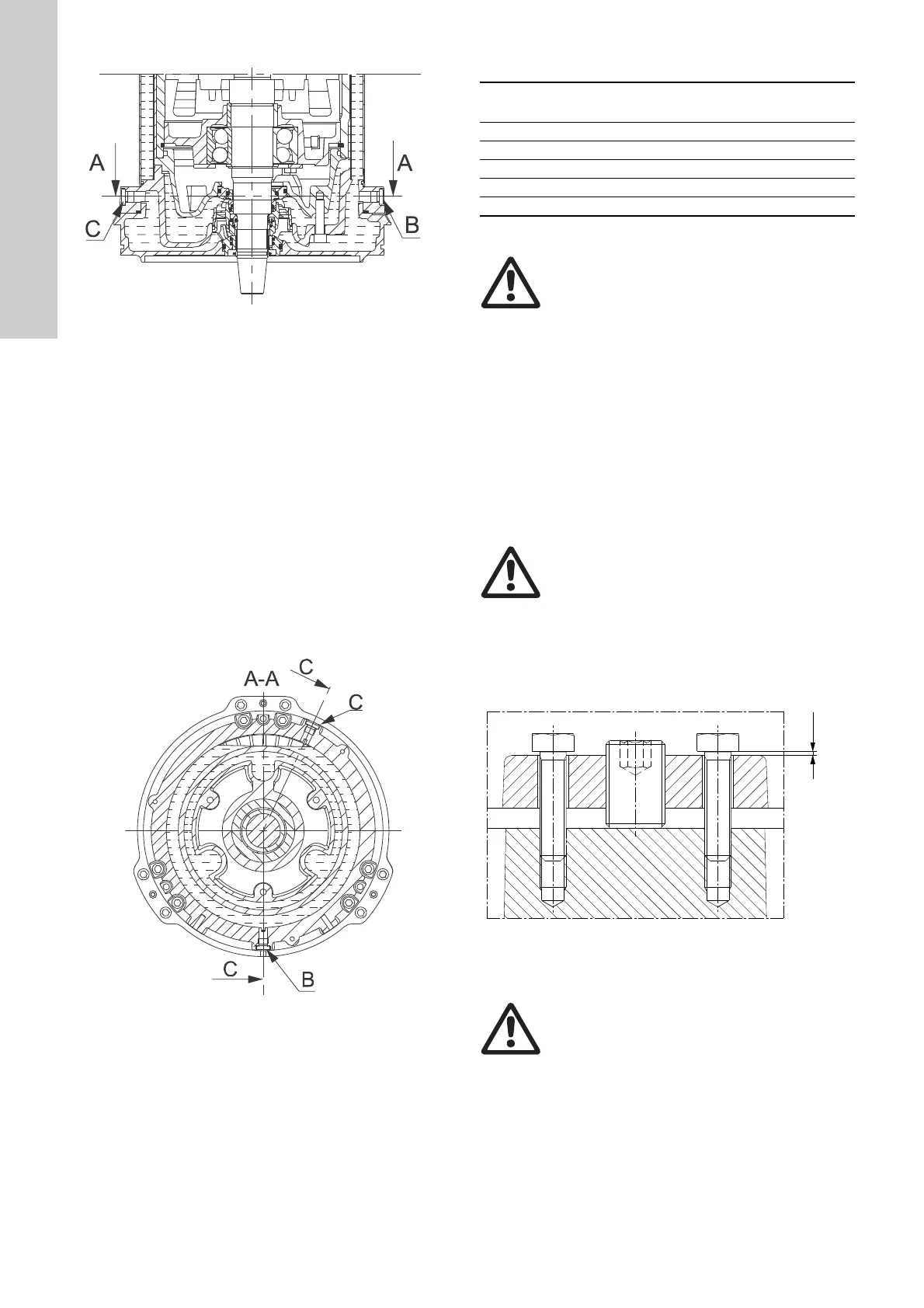

10.2 Inspection and adjustment of impeller clearance

Impeller clearance table

The impeller clearance of installation types S and C can be

inspected directly through the pump inlet.

See section 10.2.1 Installation types S and C.

Installation types D and H can be inspected and adjusted with the

pump installed on the base stand and connected to the pipework.

Inspect and adjust the impeller clearance as described in section

10.2.2 Installation types D and H.

10.2.1 Installation types S and C

1. Loosen the set screws by two full turns each.

2. Close the impeller clearance by lightly tightening the fastening

screws diagonally until the impeller touches the pump

housing.

3. Loosen the fastening screws to make the correct gap under

the heads of the fastening screws, see fig. 16, and use the

measure stated in the impeller clearance table above.

4. Tighten the set screws tightly.

5. Tighten the fastening screws diagonally.

Fig. 16 Impeller clearance adjustment, types S and C

TM05 2775 0512

Pressure range

Impeller clearance X

[mm]

E = Extra low pressure 0.9 ± 0.1

L = Low pressure 0.9 ± 0.1

M = Medium pressure 0.6 ± 0.1

H = High pressure 0.6 ± 0.1

S = Super high pressure 0.5 ± 0.1

Warning

Before inspection, make sure that the motor is

switched off and that the mains switch is locked

in position 0.

Warning

Do not use too much force when tightening the

fastening screws as this may damage the bear-

ings. The movement is usual 1 to 3 mm.

TM05 1916 3911

Warning

Do not use too much force when tightening the

fastening screws as this may damage the bear-

ings.

X mm

Set screw

Fastening screw

Fastening screw

Loading...

Loading...