English (GB)

11

4. Delivery and handling

The pump is supplied from the factory in suitable packing in which

it should remain until installation. Make sure that the pump cannot

roll or fall over.

4.1 Transportation and storage

All lifting equipment must be rated for the purpose and checked

for damage before any attempt to lift the pump. The lifting

equipment rating must under no circumstances be exceeded.

The pump weight is stated on the pump nameplate.

For long periods of storage, the pump must be protected against

moisture and heat.

Transportation and storage temperature: -20 °C to +60 °C.

After a long period of storage, the pump should be inspected

before it is put into operation. Make sure that the impeller can

rotate freely. Pay special attention to the condition of the shaft

seals and the cable entry.

4.2 Lifting points

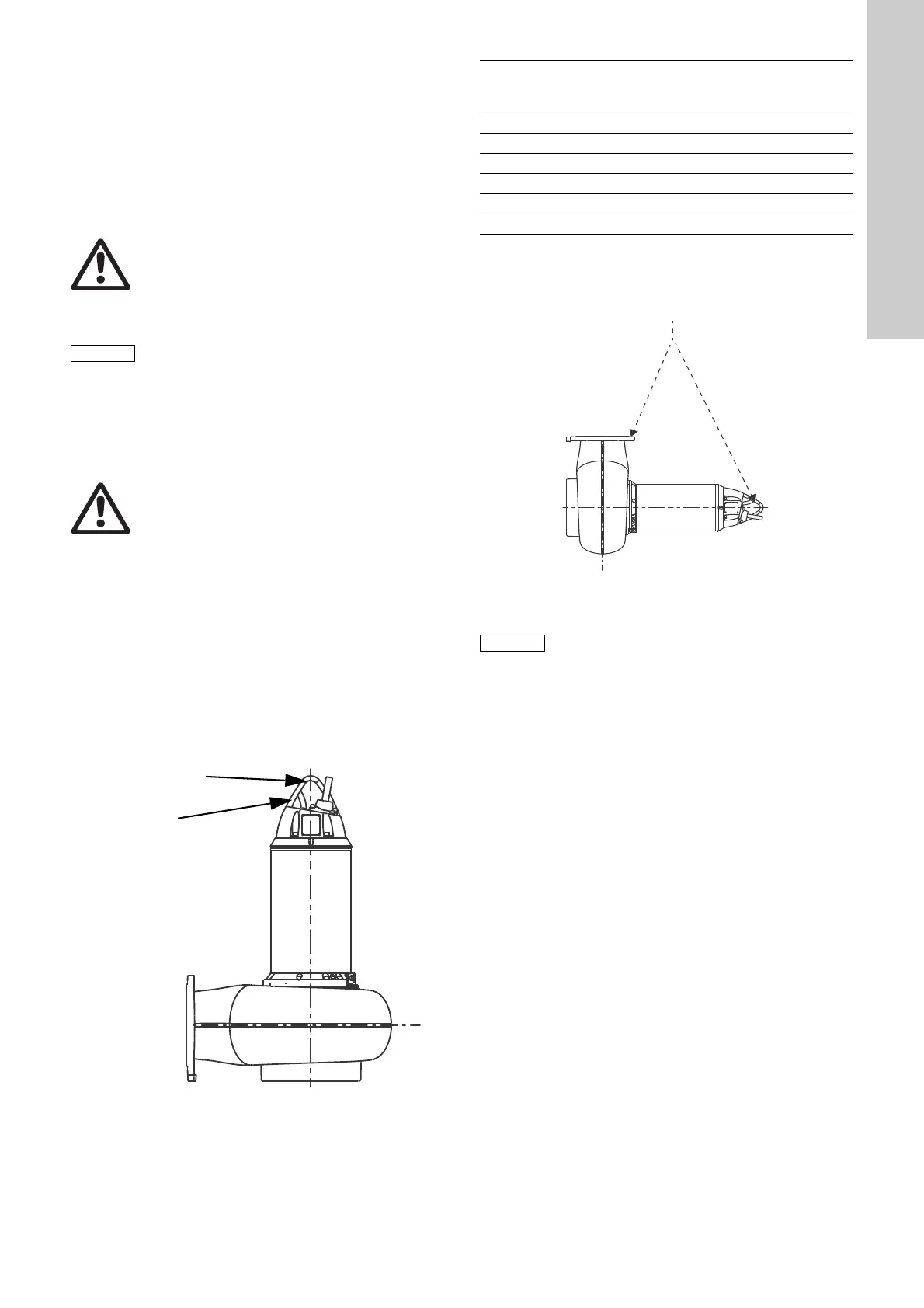

4.2.1 Installation types S/C/D

When lifting the pump, it is important to use the right lifting point

to keep the pump balanced. SE/SL pumps installation types

S/C/D are equipped with two lifting points (see fig. 2 and the table

below to find the correct lifting points) which ensure that the pump

can be lifted in a safe manner.

Fig. 2 Lifting points, installation type S/C/D

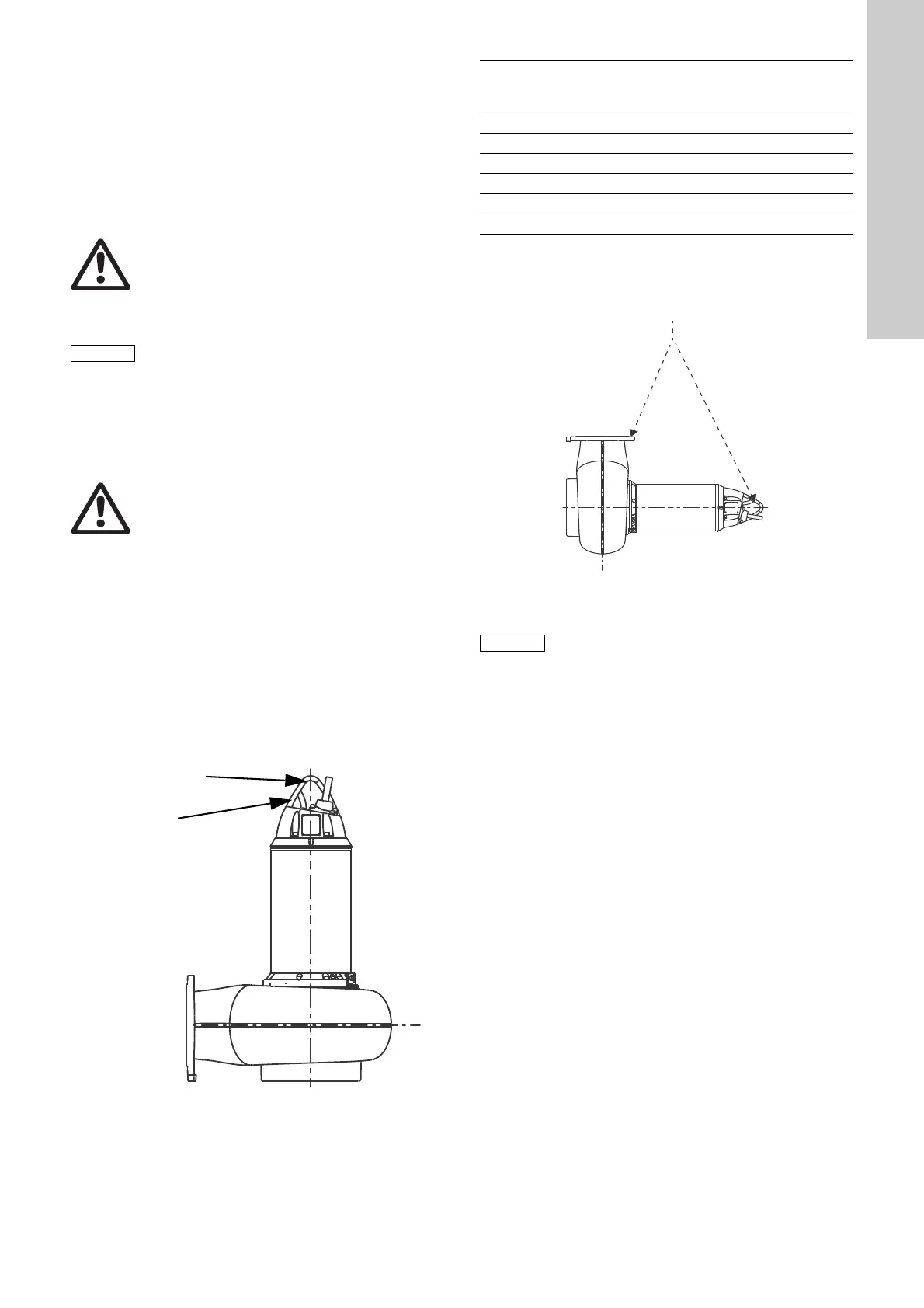

4.2.2 Installation type H

Installation type H can be lifted by using a hole in the flange and

the middle lifting point. See fig. 3.

Fig. 3 Lifting points, installation type H

Warning

Always lift the pump by its lifting bracket or by

means of a fork-lift truck, never by means of the

motor cable or the hose/pipe.

Do not remove the insulation from the free end of

the supply cable until the electrical connection is

to be made. Whether insulated or not, the free

cable end must never be exposed to moisture or

water. Non-compliance with this may cause

damage to the motor.

Warning

If the pump is stored for more than one year or it

will be a long time before it is put into operation

after the installation, the impeller must be turned

at least once a month.

TM05 2684 0312

Discharge flange size

Pump frame size

52

DN 80 Middle

DN 100 Middle

DN 150 Middle

DN 200 Front

DN 250 Front

DN 300 Front

TM05 3449 1312

Always handle the pump by means of the correct

lifting points.

Loading...

Loading...