English (GB)

10

3.2 Operating conditions

pH value

All pumps can be used for pumping liquids with a pH value

between 4 and 10.

SE/SL pumps in permanent installations can cope with the

following pH values:

Material versions S and Q: 4 to 10

Material versions R and D: 1 to 14

Liquid temperature

0 °C to +40 °C.

For short periods (max. 3 minutes), a temperature of up to +60 °C

is permissible.

Ambient temperature

The ambient temperature may exceed +40 °C for a short period

(max. 3 minutes).

Density and viscosity of pumped liquid

When pumping liquids with a density and/or a kinematic viscosity

higher than that of water, use motors with correspondingly higher

outputs.

Flow velocity

It is advisable to keep a minimum flow velocity to avoid

sedimentations in the piping system. Recommended flow

velocities:

• in vertical pipes: 1.0 m/s

• in horizontal pipes: 0.7 m/s

Installation depth

Maximum 20 metres below liquid level.

Maximum solids size

From 75 to 160 mm, depending on pump size.

3.2.1 Operating mode

The pumps are designed for continuous operation or for

intermittent operation with the maximum number of starts per

hour stated in the table below:

3.2.2 Enclosure class

IP68.

3.2.3 Level of pumped liquid

For a submerged pump, installation type C, the lowest stop level

must always be above the pump housing.

To ensure adequate cooling of the motor during operation, the

following minimum requirements must be met:

• Installation type S

For S1 operation (continuous operation), the pump must

always be covered by the pumped liquid to the top of the

motor. For S3 operation (intermittent operation), the pump

must always be covered by the pumped liquid to the middle of

the motor.

• Installation type C

The pump housing must always be covered by the pumped

liquid.

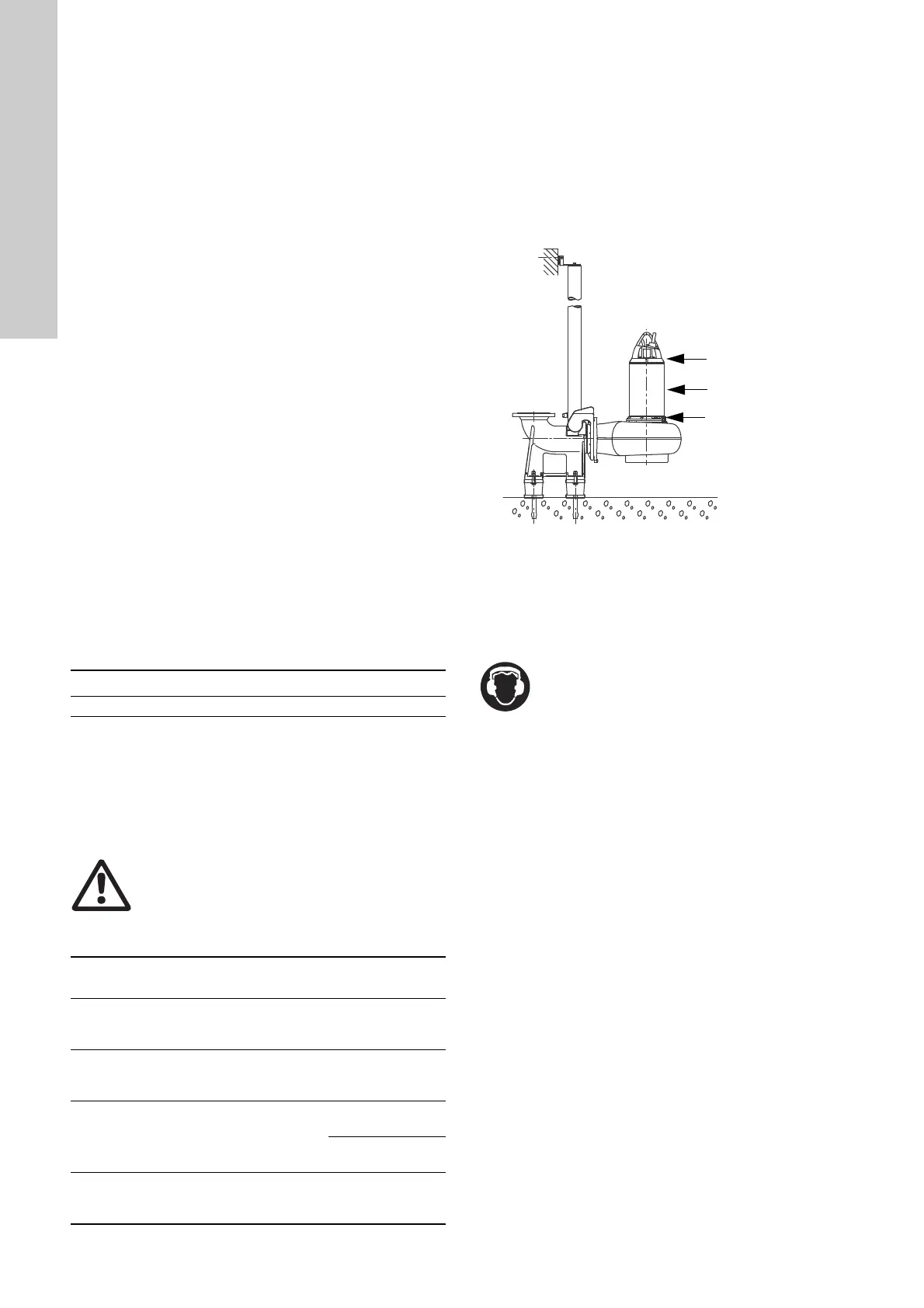

Fig. 1 Liquid level

• Installation types D and H

No special requirements.

3.3 Sound pressure level

3.4 Motor liquid

The motor is factory-filled with Grundfos motor liquid SML-3

which is frost-proof down to -20 °C. The motor liquid helps to

transfer the heat generated by the motor to the cooling chamber

and on to the pumped liquid passing through the pump.

SE/SL pump Starts per hour

9-30 kW 20

Warning

Dry-running is not allowed.

The level of pumped liquid must be controlled by

level switches connected to the motor control

circuit. The minimum level depends on the

installation type and is specified in these

installation and operating instructions.

Installation

type

Description Accessories

S

Sewage pump without

cooling jacket for submerged

installation on auto coupling.

Auto coupling

C

Sewage pump with cooling

jacket for submerged

installation on auto coupling.

Auto coupling

D

Sewage pump with cooling

jacket for dry vertical

installation.

Base stand

installation

Base plate

installation

H

Sewage pump with cooling

jacket for dry horizontal

installation.

Base stand for

horizontal

installation

TM05 2535 0212

Warning

Depending on the installation type, the sound

pressure level of the pump can be higher than

70 dB(A).

When working nearby such an installation in

operation, hearing protection must be used.

Liquid levels for installation

types S and C:

S1 operation and Ex

pumps, installation

type S

Installation type C

S3

Loading...

Loading...