English (GB)

21

10.1 Checking and changing the motor liquid

10.1.1 SL pumps

The shaft seal housing has two screws: A and B.

Screw A is for filling motor liquid into the shaft seal housing.

Screw B is for checking the level of motor liquid and for draining

motor liquid from the shaft seal housing.

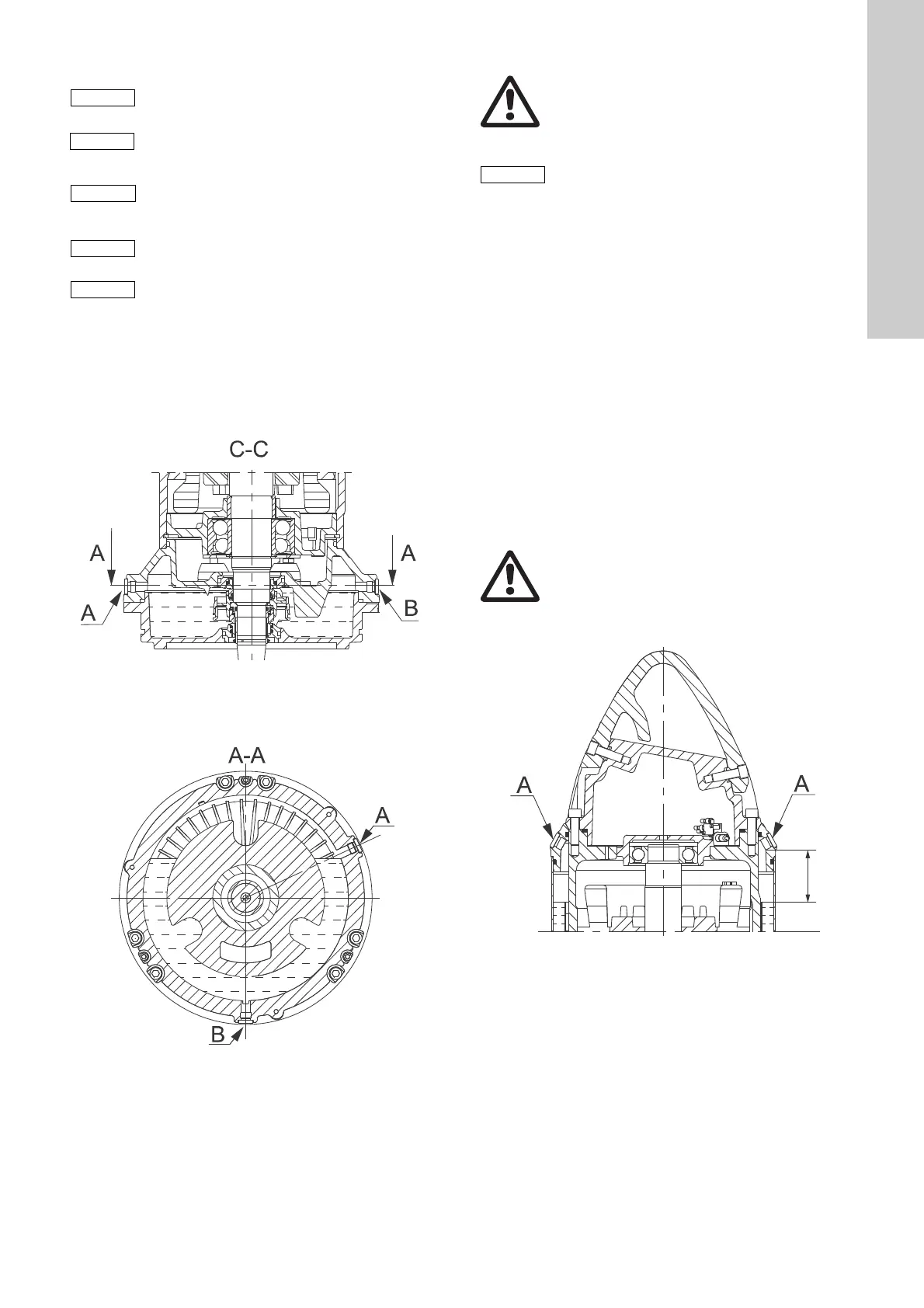

See fig. 11 which applies to installation type S.

Fig. 11 SL pump, vertical view

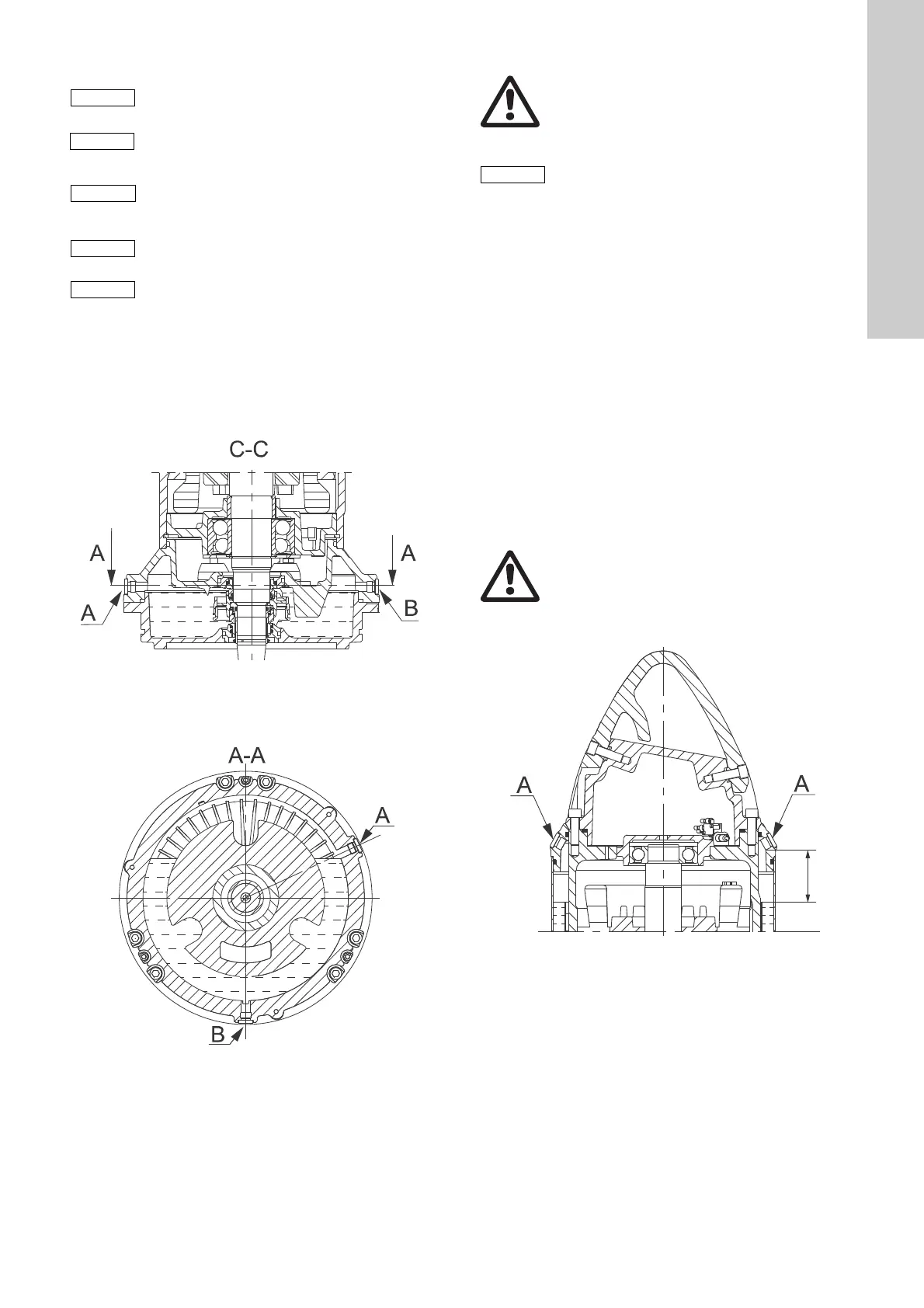

For SL pump, installation type S, the motor liquid level can be

checked by removing screw A. See fig. 12.

Fig. 12 SL pump, horizontal view

Draining motor liquid, horizontal and vertical installation:

Place a container under the pump to collect all the drained-off

motor liquid; then place the pump in a horizontal position.

Remove screw B, fig. 12, which is facing downwards. Allow all

motor liquid to drain from the housing into the container.

Filling motor liquid, vertical installation:

While the pump is standing vertically, fill the shaft seal housing

with motor liquid through hole A until the motor liquid level

reaches hole B. See fig. 11. Replace the O-rings with new rings,

insert the screws and tighten securely.

Filling motor liquid, horizontal installation:

Place the pump horizontally with plug B mounted and facing

downwards. Fill the shaft seal housing with motor liquid through

hole A until the motor liquid reaches the level according to fig. 12.

Replace the O-ring with new ring, insert screw A and tighten

securely.

10.1.2 SE pumps

The shaft seal housing has three screws: A, B and C.

Screw A is used both for checking the level of motor liquid and for

filing motor liquid.

Screw B is used for draining motor liquid from the shaft seal

housing.

Screw C is used both for checking the level of motor liquid and for

filing motor liquid but only in installation type H. See fig. 15.

Fig. 13 SE pump, motor liquid level, top view

Clean the outside of the pump at regular intervals

in order to retain the heat conductivity.

Change the motor liquid every four years to

prevent oxidation.

There must be a minimum of 10 % air in the shaft

seal housing due to thermal expansion of the

motor liquid during operation.

Lack of motor liquid may cause overheating and

damage of the mechanical seals.

Use motor liquid SML3.

TM05 2768 0612TM05 2768 0612

Warning

When loosening screw B of the shaft seal

housing, note that pressure may have built up in

the chamber. Do not remove the screw until the

pressure has been fully relieved.

Used motor liquid must be disposed of in

accordance with local regulations.

Warning

When loosening screw A of the shaft seal

housing, note that pressure may have built up in

the chamber. Do not remove the screw until the

pressure has been fully relieved.

TM05 2774 0512

Loading...

Loading...