8.2 Control signals

8.2.1 Digital low-voltage PWM signal

WARNING

Explosive environment

Death or serious personal injury

‐ Do not exceed the specified maximum voltage on the

PWM output or the output circuit may overheat.

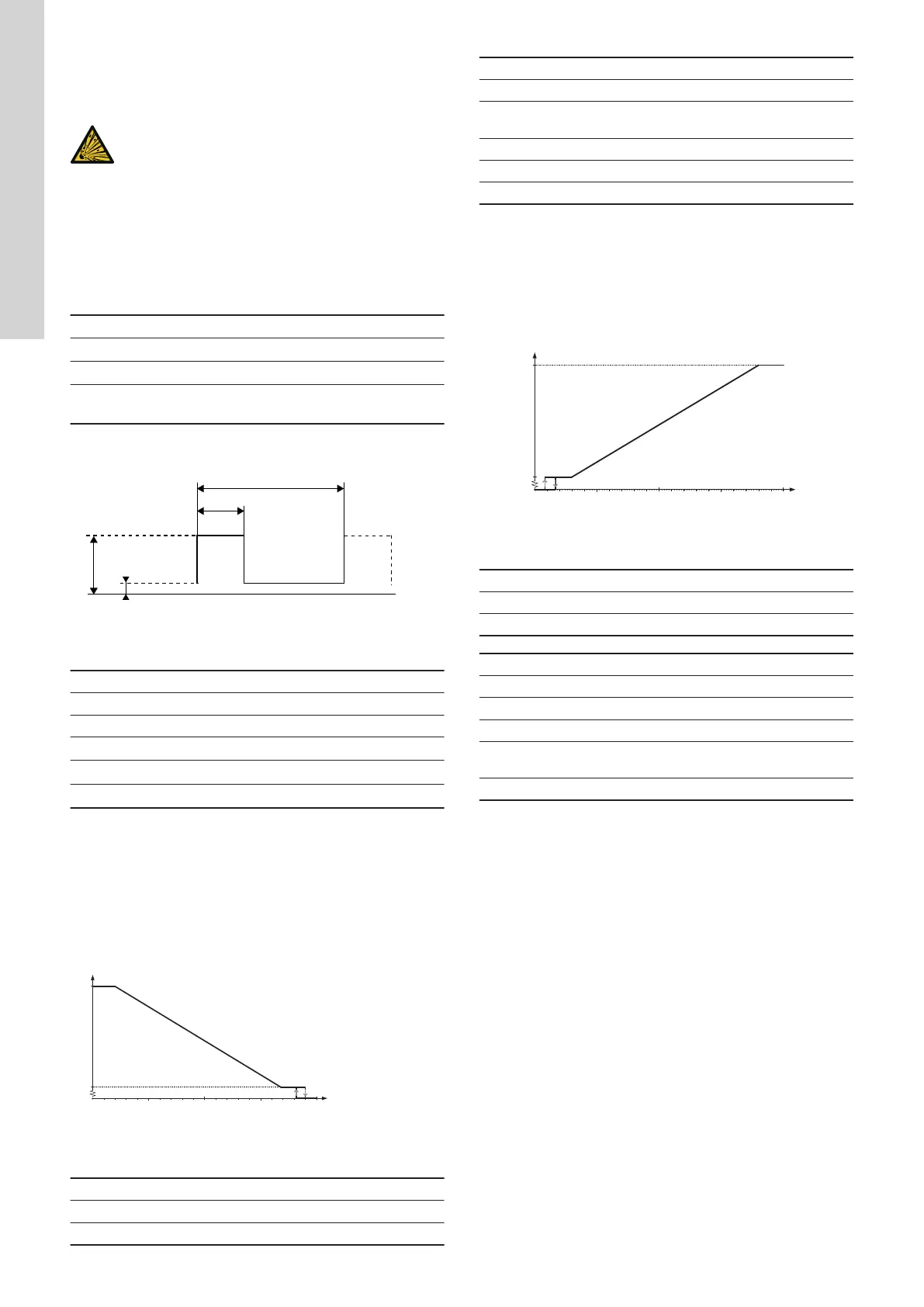

The square-wave PWM signal is designed for a 100 to 1500 Hz

frequency range. The PWM signal is used to select the speed

(speed command) and as feedback signal. The PWM frequency on

the feedback signal is fixed at 75 Hz in the pump.

Duty cycle

d % = 100 x t/T

Example Rating

T = 2 ms (500 Hz)

U

IH

= 4-24 V

t = 0.6 ms

U

IL

≤ 1 V

d % = 100 x 0.6 / 2 = 30 %

4.5 mA ≤ Ih ≤ 10 mA (depending on

U

IH

)

Example

TM049911

PWM signal

Abbreviation Description

T Period of time [sec.]

d Duty cycle [t/T]

U

IH

High-level input voltage

U

IL

Low-level input voltage

I

IH

High-level input current

8.2.2 PWM input signal profile A (heating)

At high PWM signal percentages (duty cycles), a hysteresis

prevents the pump from starting and stopping if the input signal

fluctuates around the shifting point. At low PWM signal

percentages, the pump speed is high for safety reasons. In case a

cable breaks in a gas boiler system, the pumps will continue to run

at maximum speed to transfer heat from the primary heat

exchanger. This is also suitable for heat pumps to ensure that the

pumps transfer heat even if a cable breaks.

Max.

10

20

30 40

50 60 70

80

90

100

X

Y

TM049985

PWM input profile A (heating)

Axis Value

X PWM input signal [%]

Y Speed

PWM input signal [%] Pump status

≤ 10 Maximum speed

> 10 / ≤ 84

Variable speed from minimum to maxi-

mum speed

> 84 / ≤ 91 Minimum speed

> 91/95 Hysteresis area: on/off

> 95 / ≤ 100 Standby mode: off

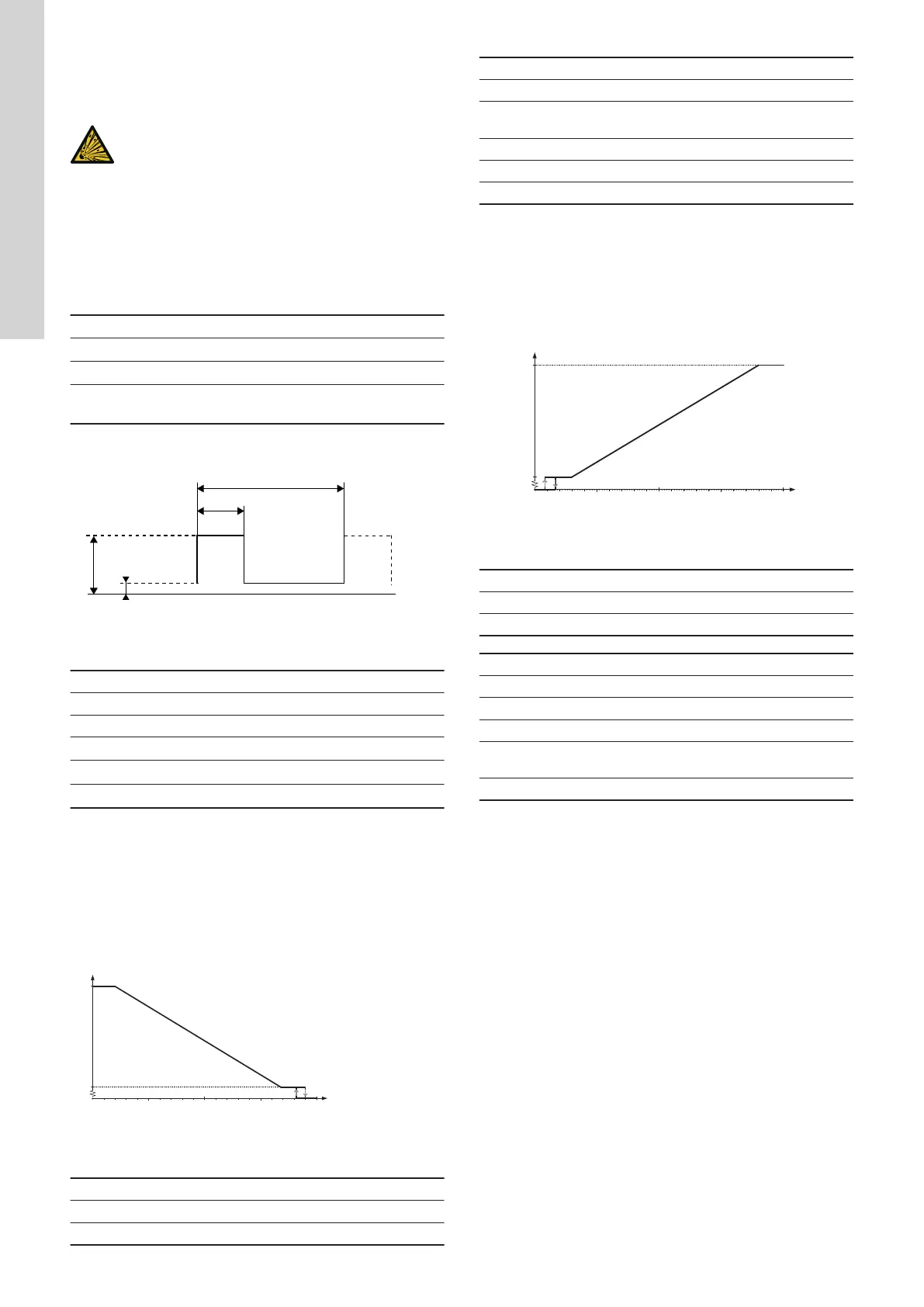

8.2.3 PWM input signal profile C (solar)

At low PWM signal percentages (duty cycles), a hysteresis prevents

the pump from starting and stopping if the input signal fluctuates

around the shifting point. Without PWM signal percentages, the

pump stops for safety reasons. If a signal is missing, for example if

a cable breaks, the pump stops to avoid overheating of the solar

thermal system.

Max.

10 20

30

40 50

60

70

80

90 100

TM051575

PWM input profile C (solar)

Axis Value

X PWM input signal [%]

Y Speed

PWM input signal [%] Pump status

≤ 5 Standby mode: off

> 5 / ≤ 8 Hysteresis area: on/off

> 8 / ≤ 15 Minimum speed

> 15 / ≤ 90

Variable speed from minimum to maxi-

mum speed

> 90 / ≤ 100 Maximum speed

8.2.4 PWM feedback signal (standard)

The PWM feedback signal offers the same pump information as in

bus systems:

• current power consumption (accuracy ± 2 % of PWM signal)

• warning

• alarm

• operating status.

Alarms

Alarm output signals are available because some PWM output

signals are dedicated to alarm information. If a supply voltage is

measured below the specified supply voltage range, the output

signal is set to 75 %. If the rotor is locked due to deposits in the

hydraulics, the output signal is set to 90 % as this alarm has a

higher priority.

16

English (GB)

Loading...

Loading...