appliance is stored for months after being wet tested.

Before, during and after the deblocking, the device is tight

and must not release any water.

TM059253

Deblocking device

TM060291

Sectional drawing of deblocking device

Shaft with rotor

The shaft is made of ceramics. To avoid precipitation of

calcium in the radial bearings, the shaft has been plunge-

ground at the journal bearings. It has a through-going hole

to ensure good lubrication and cooling of the upper

bearing. The rotor can does not need to be vented as air

inside the rotor chamber will escape the system through

the through-going hole of the shaft.

The rotor core is either made of bonded neodymium

permanent magnets, or injection-moulded with PPS

bonded hard ferrite magnetic particles. The rotor is

encapsulated in a thin stainless-steel cladding welded to

the end covers. The rotor is fixed on the shaft by a back

iron with a bush. After assembly the whole unit is

balanced.

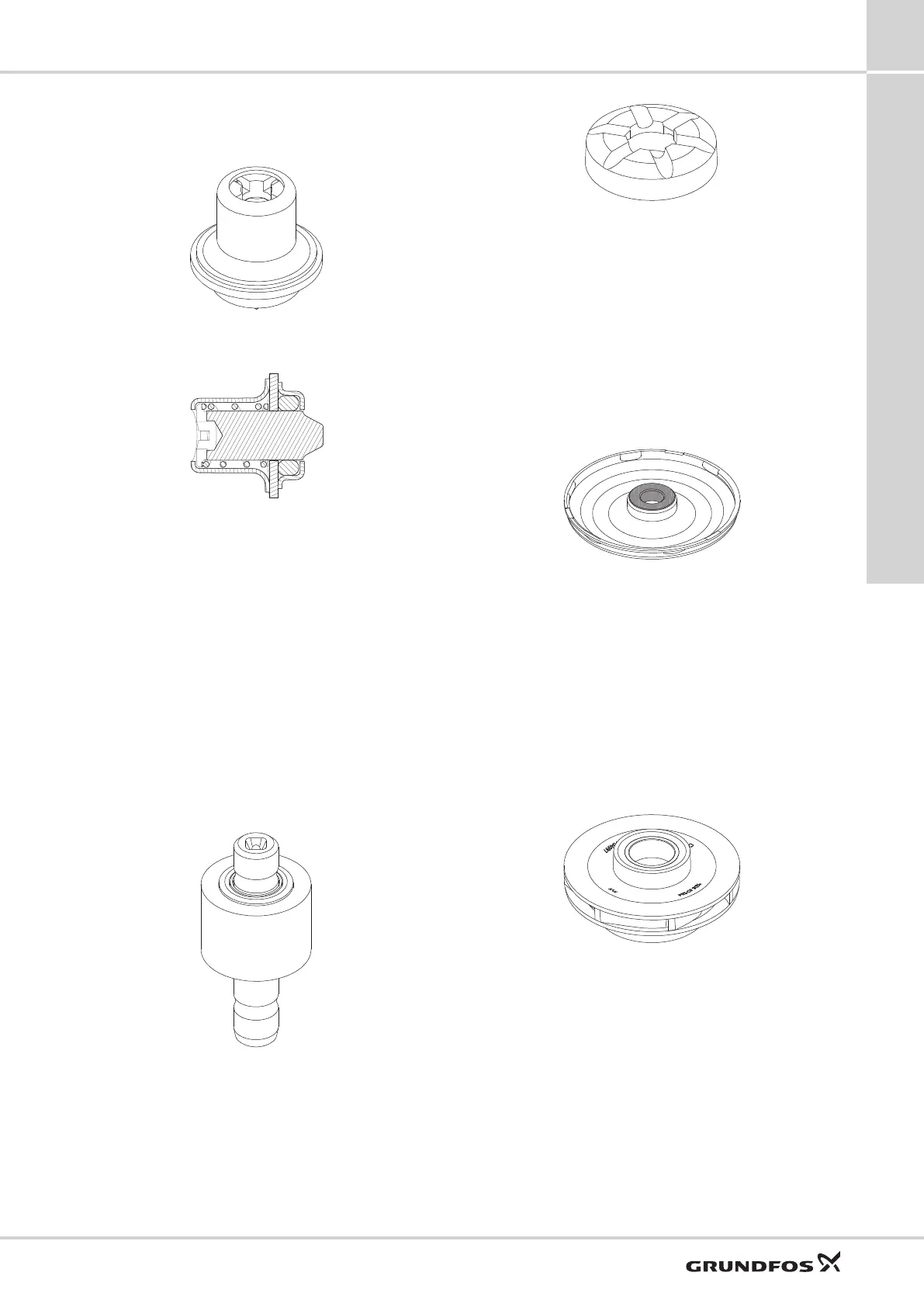

TM059250

Shaft with rotor

Thrust bearing

The antimony-free carbon thrust bearing is fitted to the

shaft in a flexible EPDM retainer.

In combination with the bearing plate, the thrust bearing

prevents forces from being transmitted axially to rotor and

rotor can.

TM059252

Thrust bearing

Bearing plate

The bearing plate is made of stainless steel. The ground

and honed inner radial and axial ceramic bearing is

pressed into the bearing plate. The axial bearing is lapped

to reduce any friction and the run in period of the pump.

Due to the relatively large bearing plate surface, the motor

heat is effectively carried away by the pumped liquid. Tiny

laser holes through the bearing plate ensure optimum

venting and minimise the gradual replacement of rotor

liquid with the pumped liquid.

TM059249

Bearing plate with ceramic bearing

Impeller

The composite impeller is of the radial type with curved

blades. The impeller shaft with rotor and bearing plate is

assembled in one unit to eliminate possible misalignment

in the bearings.

Three types of impellers are used:

• UPM3 Standard: diameter 38 mm, clearance 3 mm

• UPM3 SOLAR: diameter 52 mm, clearance 2.5 mm

• UPMO: diameter 48 mm, clearance 3 mm

TM059251

Impeller

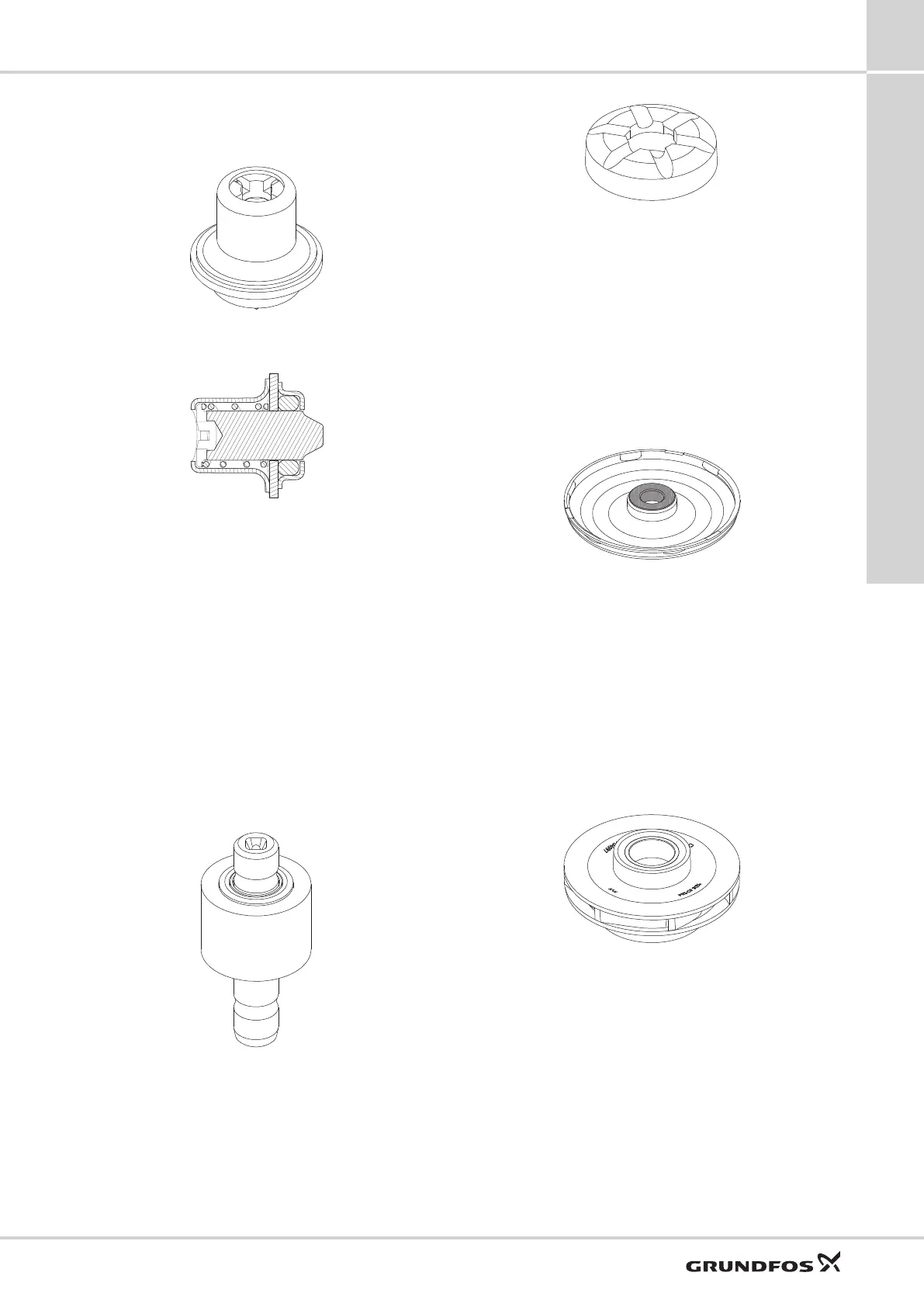

Moving unit

The unit is a pre-mounted combination of the shaft with a

rotor, thrust bearing with a retainer, bearing plate and

impeller. The moving unit is inserted into the rotor can with

the upper radial bearing. The unit runs as a bearing

system, ceramic/ceramic, with almost no wear as long as

it is lubricated. During production, the unit is lubricated

with glycerine. When the unit is mounted in a water-filled

system, the system water lubricates the bearings. This

guarantees the extremely reliable Grundfos ceramic

bearing system of wet-running pumps.

UPM3

9

37

Technical description

Loading...

Loading...