Composite PA6.6 pumps with threaded flat

sealings

Since 1989, Grundfos has been manufacturing and selling

pump housings and integrated hydraulic units of polymeric

composite, primarily PA6.6 with 30 % glass-fibre

reinforcement. When using composite, the optimal design

of connections is clip or hair-pin, because of their low

internal stress-generating level.

For threaded connections, the full thread length must be

used. The maximum assembly torque (e.g. 30 Nm ± 10) is

mentioned in the specifications of the pump. We

recommend to use EPDM gaskets.

For reason of overload risk, Grundfos does not

recommend to use composite threads for standalone

connections outside appliances.

All PA6.6 housings are defined as integrated. For

integrated pumps, the respective pump heads are tested

according to EN 16297/3 on a reference housing.

Expected lifetime of composite PA6.6

housings

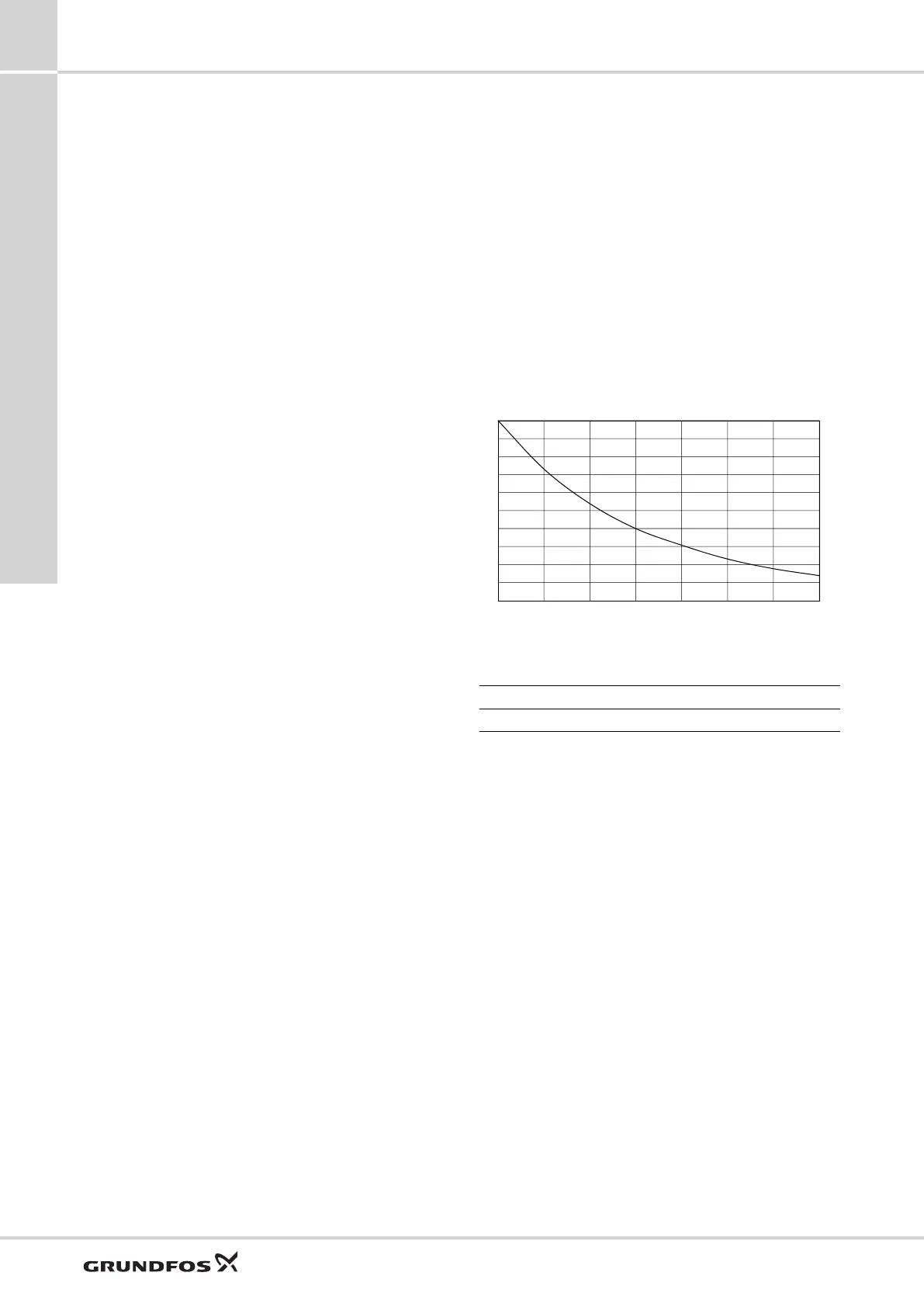

The expected lifetime of composite PA6.6 housings in

heating applications depends on the liquid temperature

and the system pressure.

The liquid temperature must not exceed 95 °C.

For composite housings, Grundfos recommends that the

system pressure does not exceed 3 bar (0.3 MPa), for

cast-iron housings 6 bar (0.6 MPa). For shorter periods of

time, for example in fault scenarios, the composite

housing can withstand 6 bar (0.6 MPa).

The expected lifetime also depends on the time/

temperature profile of the application, based on which an

equivalent constant liquid temperature can be calculated.

The influence of the liquid temperature between 60 °C

and 95 °C on the expected lifetime is shown in the

following diagram.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

60 65 70 75 80 85 90 95

TM064413

Diagram temperature/expected lifetime for PA 6.6 30 %

GF

X-axis Constant liquid temperature [°C]

Y-axis Expected lifetime factor

Related information

Liquid temperature

UPM3

9

42

Technical description

Loading...

Loading...