!

"

!

Planer-Thicknesser

A3-26 / A3-31 / A3-41

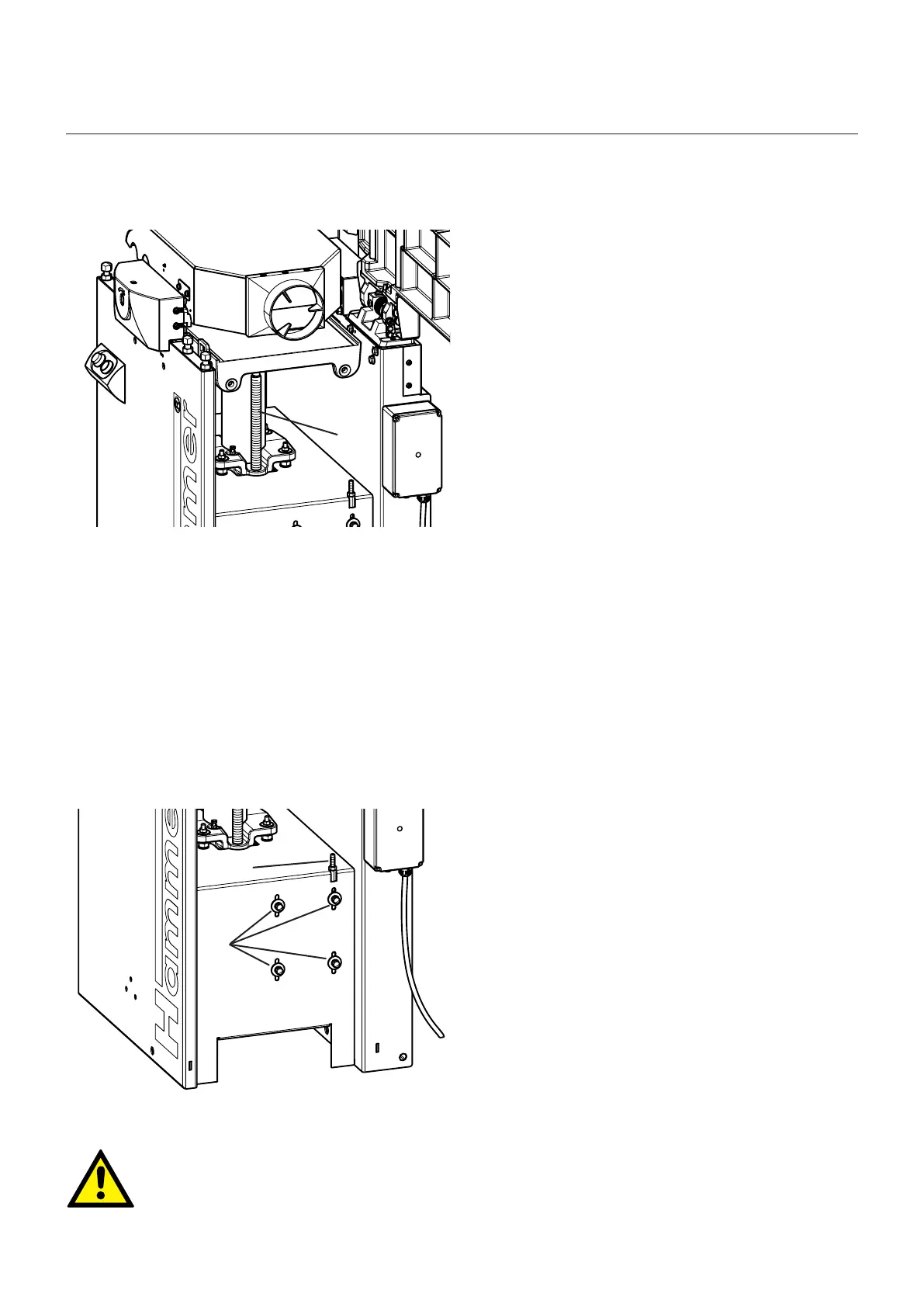

10.3.3 Greasing the height spindle (thicknesser planing table)

1. Before beginning any maintenance work on the

machine, switch it off and secure it against acciden-

tally being switched on again.

2. Loosen the clamping lever.

3. Use the system handwheel to move the thicknessing

table all the way up

4. Clean the spindles and lubricate with regular machi-

ne grease.

5. Use the system handwheel to move the thicknessing

table all the way down and then all the way back up

again.

6. Clamp the clamping lever.

! Thicknesser table height spindle

" Lubrication hole

# Single-hand clamping lever

Fig. 10-4: Lubricating the height spindle

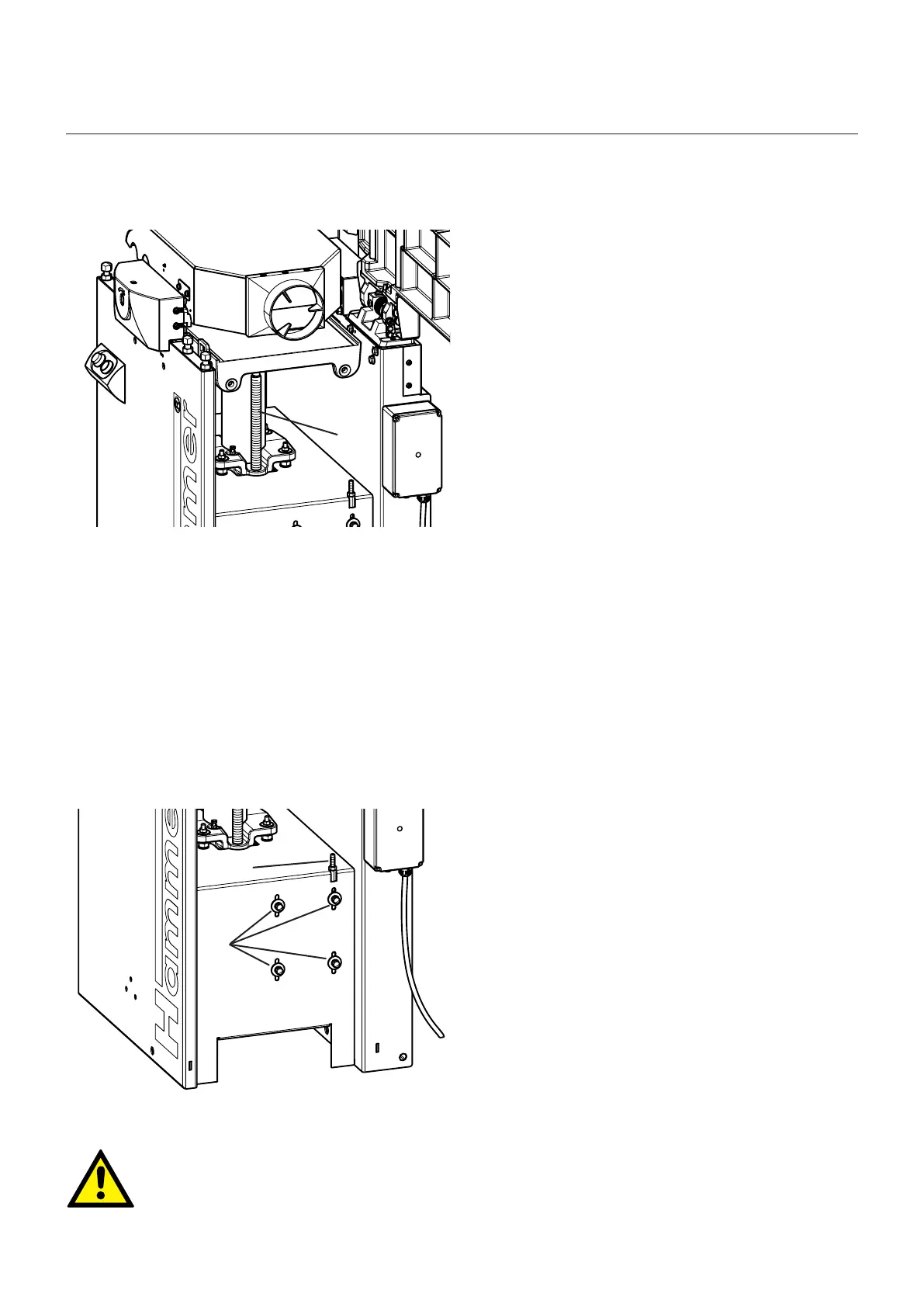

Over time, the drive belt will lose its capacity to transmit

power. At this point, the drive belt must be re-tensioned

or replaced.

The drive belt must be inspected monthly; if tears are

discovered, the drive belt must be replaced.

10.3.4 Retensioning the drive belt

1. Before beginning any maintenance work on the

machine, switch it off and secure it against acciden-

tally being switched on again

2. Set the gear lever to the “0” setting.

3. Loosen the nuts.

4. Use the belttensioning screw to tension the

drive belt.

5. Tighten the nuts

! Tightening screw

" Nuts

Attention! Risk of material damage!

Do not over-tension the drive belt!. Turn the belt-tensioning screw only until the drive belt is sufficiently

tensioned to transmit power effectively.

Fig. 10-5: Retensioning the drive belt

Service

Loading...

Loading...