Technical Manual VERSION 2.0 -10-18-2018

68

6. Operation and maintenance

6.1 Compressor startup

PRESTART CHECKING Table below shows the required procedures and checkpoints before startingup the

compressor during commissioning or initial operation of the unit.

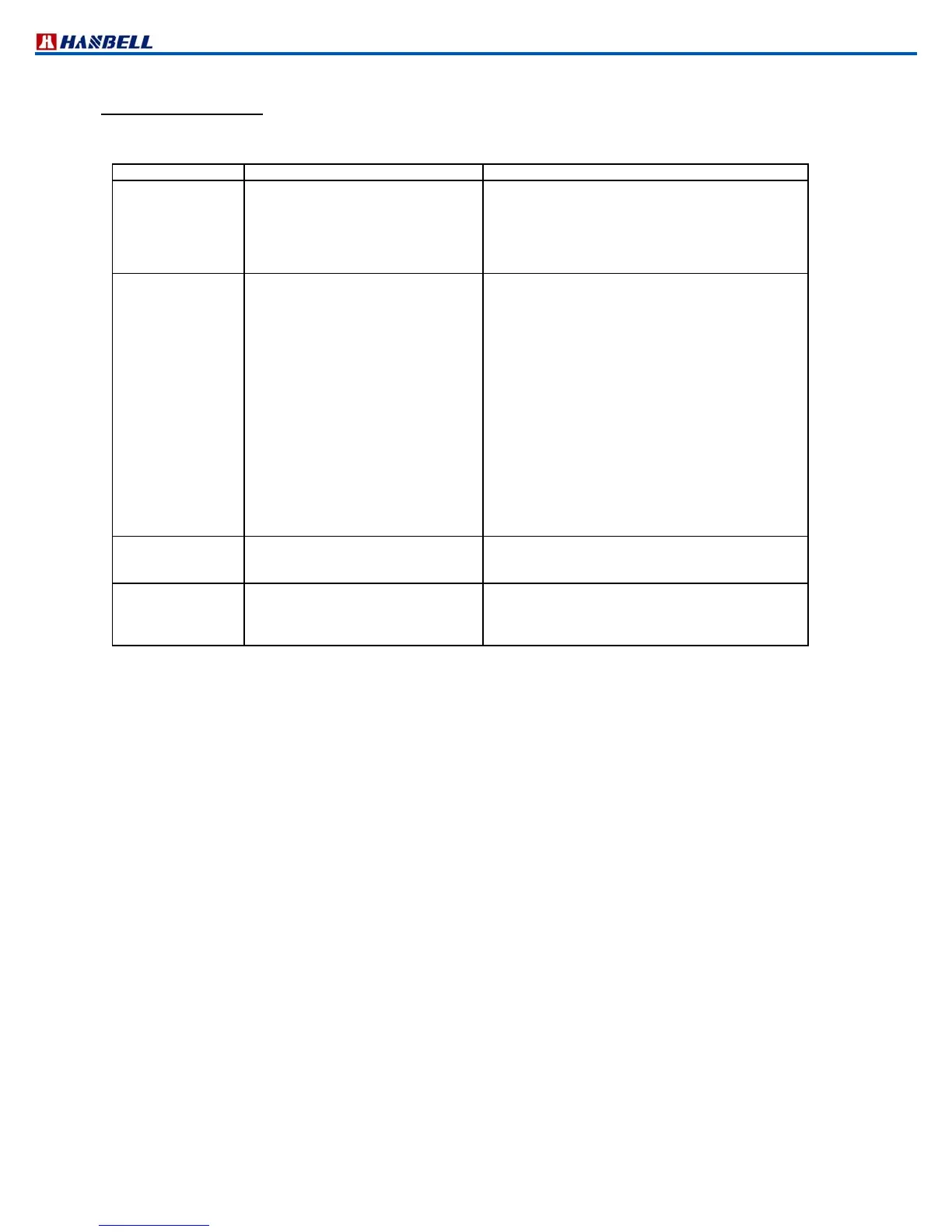

Items Things to be checked States or standard values

1. Accessories

1. Oil level

2. Oil heater

3. System valves status

4. Solenoid valves

5. Capillary

1. Higher than the middle line of oil level sight glass

2. Should be kept energizing after compressor shut

down.

3. Opened

4. Fixed

5. No serious distortion or damaged

2. Electrical system

1. Voltage of main power

2. Voltage of control circuit

3. Insulation resistance value of the

motor between phase to phase and

phase to ground.

4. Power terminals and wire cables’

terminal s connection.

5. Grounded

6. Capacity of electrical accessories

7. Settings of switches, sensors and

controllers.

1. Electricity voltage should be kept within 5

rated voltage, instant maximum voltage drop while

starting should be less than 10% to the rated

voltage.

2. Standard voltage

voltage is 230V.

If there is other demand, contact HANBELL.

3. Insulation resistance value should be above 5M.

4. Power terminals are firmly fixed on terminal block

and well insulated. Keep wire cables away from

heat source and sharpened metal. Power terminals

are fixed firmly

and well insulated. Terminal screw

and block are both required.

5. (Ruled by the local Electricity Regulations.)

6. Properly selected (or inquired by the system

designer.)

7. Properly set (or inquired by the system designer.)

3. Piping system

1. Outer piping system

2. Leakage test

3. Bolts to fix the compressor.

1. Fixed firmly.

2. No leakage.

3. Fix the compressor tightly.

4. Safety devices

1. Motor coil sensor (thermistor)

2. Discharge sensor (thermistor)

3. Controller

1. Connected in series with disch

controller.

2. Connected in series with motor sensor to controller.

3. Closed circuit with N.C. & N.O.

In addition to the prestart checking given in the above table, please also consider the following:

a. It is necessary to pay more attention to the auxiliary facilities while the chiller is commissioning at the jobsite and the

periodic maintenance after the initial startup.

b. For a new chiller with compressor put in stock for a long time, it is recommended to add 1 to 1.5 liter of oil in the

motor casing to provide better screw rotor lubrication during compressor’s initial startup.

c. In order to keep the capacity control smoothly under the low ambient temperature with the normal viscosity of oil, oil

heater should be kept energizing after compressor has been shut down for preparation for the next startup.

d. Check that all the settings on each pressure switch are correct.

e. Check if all the stop valves in the system are already open.

f. Check the rotating direction of the compressor by starting the compressor for a split second (approx. 0.51 sec.) and

check the suction and discharge pressure gauges. The correct rotating direction is: suction pressure drops immediately

and the discharge pressure will go up.

g. Compressor’s lubrication oil should be checked immediately after starting. Oil level should be within sight glass

range or higher than the middle line of oil level sight glass.

h. Oil foaming can be generated during starting phase, but it should reduce when the compressor is under stable

operating conditions. Otherwise this can indicate excessive liquid in the suction gas.

i. The running condition of compressor after commissioning at the jobsite should be adjusted as; the discharge

temperature will be at least 20K above the saturated condensing temperature and the suction vapor superheat should

be within 10K to the saturated evaporating temperature.

j. The whole plant, especially the pipelines and capillary tubes must be checked for abnormal vibrations. Please contact

HANBELL or local distributor if any abnormal vibrations or noise found while compressor is running.

k. Regularly check the plant according to national regulations and the following items should also be checked:

●Operating data of the machine

●Check the lubrication/ oil level

●All compressor protection devices

●Check electrical cable connections and tightness

Loading...

Loading...