Technical Manual VERSION 2.0 -10-18-2018

75

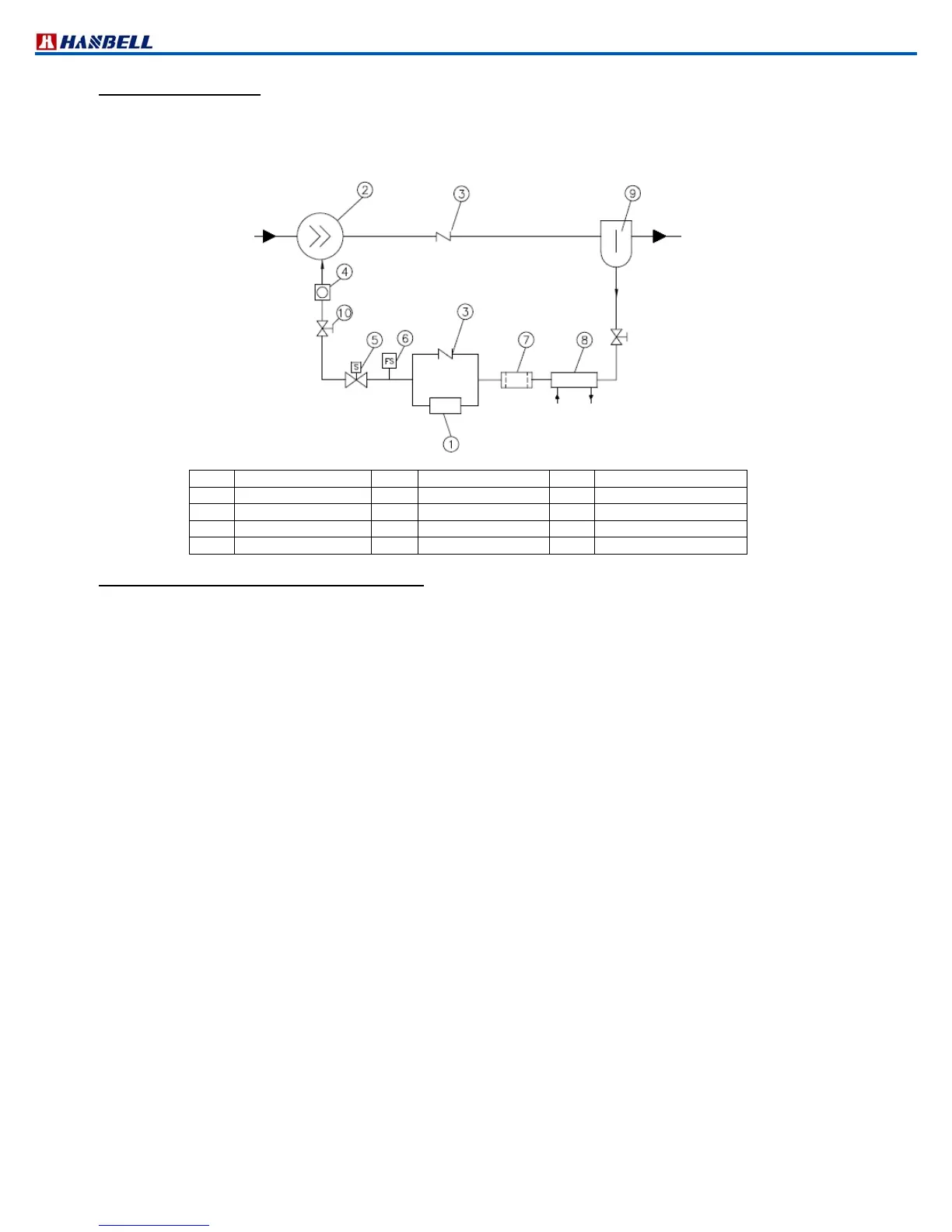

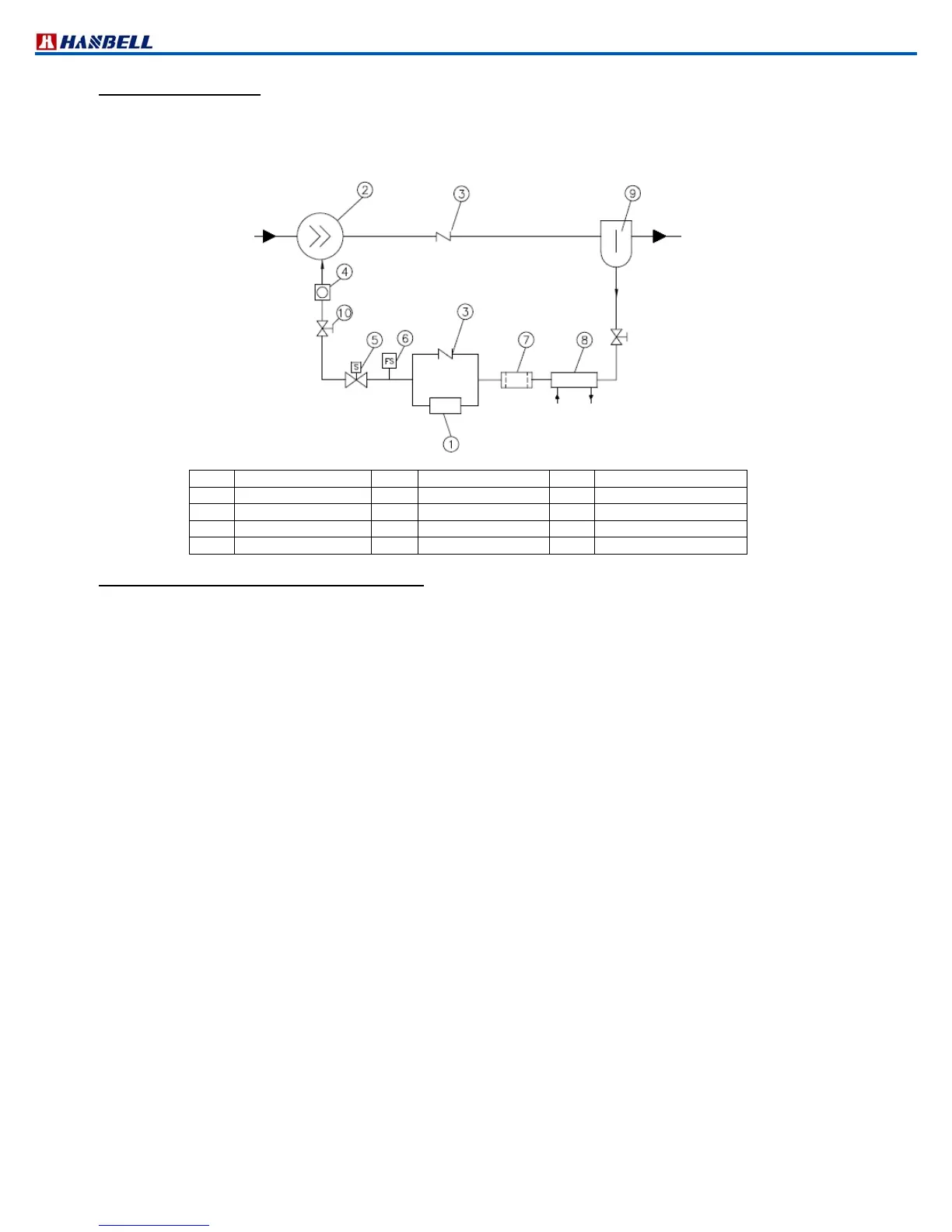

7.4 Oil pump application

An additional oil pump is recommended to install to the system when the differential pressure of oil pressure and

suction pressure is less than 4bar ( for example: water cooled flooder chiller). If compressor is operating at the

mentioned condition, the failure of modulation and lubrication will be happened and will seriously damage the

compressor. Besides the installation of additional oil pump, a high – low pressure differential switch is also

recommended to install to this kind of system. Please contact with Hanbell for more detailed information of oil pump.

Figure 72 Additional oil pump

Item

Description Item

Description Item

Description

1 Oil pump 5 Solenoid valve 9 External oil separator

2 Compressor 6 Flow switch 10 Service valve

3 Check valve 7 Oil filter cartridge

4 Sight glass 8 Oil cooler

7.5 Important note of applications of compressor

1. Pump down

Do not pump down the compressor on the chiller as a routine operation except only for temporary maintenance or a

long term shut down. Because pump down will cause extremely high temperature in the compression chamber and

overheat of the motor as well due to less amount of refrigerant in the suction side. When doing the pump down, be

sure to take notice of the items listed below :

a. Pump down should be done once each time, as it may be dangerous to the compressor, compression chamber for

pumping down repeatedly.

b. The minimum suction pressure when doing the pump down should be over 15 psig for R134a and 25 psig for R22.

c. Take notice of compressor running noise. If there is any abnormal noise happened, then emergently stop the pump

down.

2. Long term partial load operation

If compressors have to run at partial load below 50% continuously, though maybe within operation limits under such

operation condition and with temperature of motor below trip setting for overheating, insufficient dissipation of heat in

motor will occur due to lower flow rate of suction gas at partial load. If compressors operate under high temperature for

a long time, insulation of motor will deteriorate gradually at risk of serious motor damage finally. In such severe

operation conditions, Hanbell strongly recommends installation of liquid injection system to cool motor coil and use of

Pt100 or Pt1000 sensor as described in chapter 4.4s, to effectively control temperature of motor while running. It is

suggested to switch on liquid injection when temperature of motor coil is higher than 60 and turn off liquid injection ℃

when it’s lower than 50 .℃

3. Low pressure receiver

When a compressor operates in the following application conditions, installation of a low pressure receiver is

recommended in order to prevent massive liquid refrigerant from returning to the compressor under momentary

changes of operation condition.

●Heat pump ●Parallel system ●system with long piping

●operating in the low ambient temperature area ●system heating load varies extremely

Loading...

Loading...