[文件標題] [日期]

8

Vol. 1.2 © 2020 Hanbell Precise Machinery Co., Ltd.

All rights reserved

2.5 Connections

2.5.1 Suction/discharge/economizer flange size

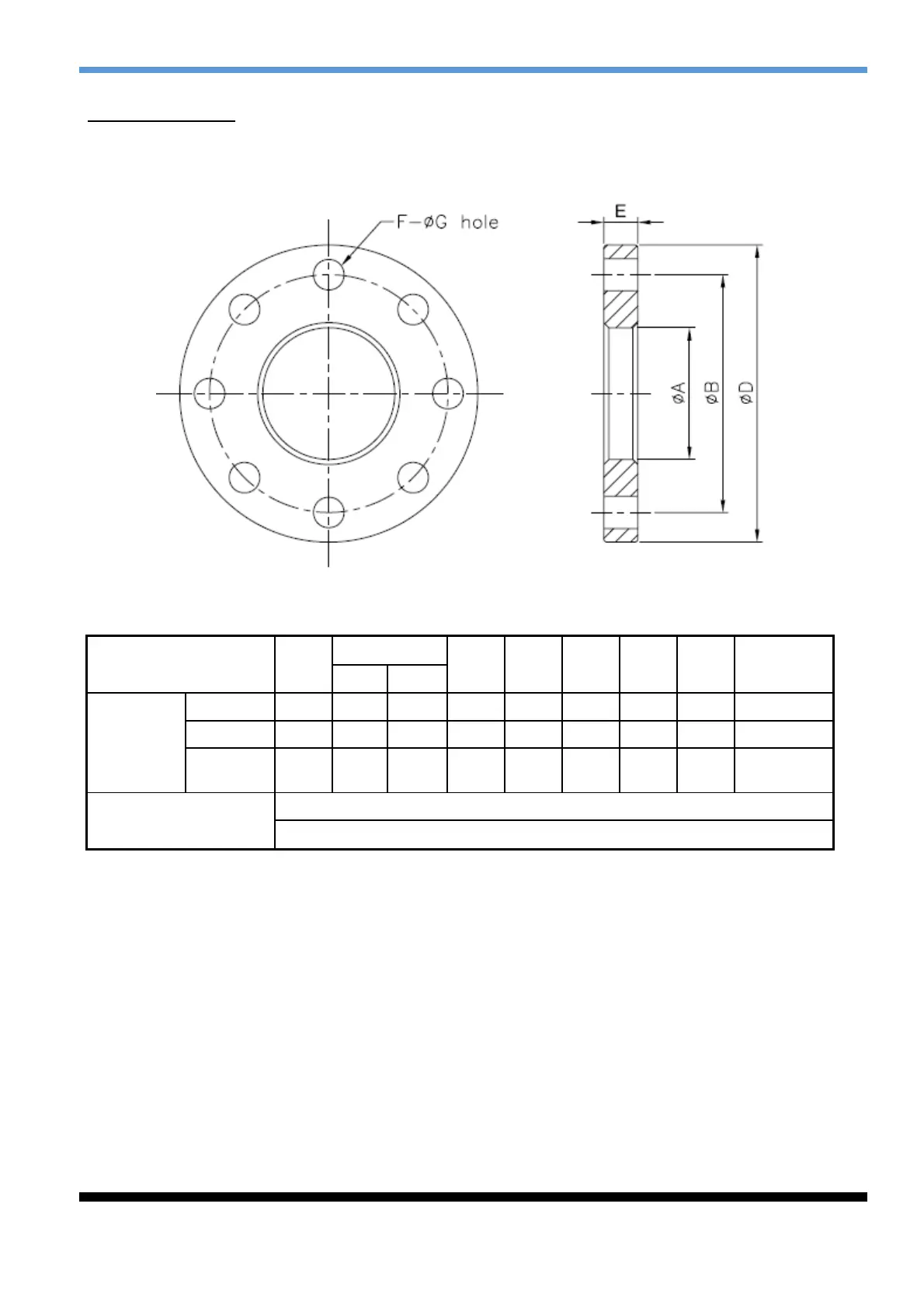

Figure 2.3 Flange

Position Size

A

B D E F G

Piping

thick.

(JIS)

(GB)

RTM-090

Suction 8" 218

221.5

305 350 30 12 25 11

Discharge

6" 167

170.5

260 305 28 12 25 10.5

Mid.-

(Eco.)

2 1/2"

77.5

77.5

140 175 20 8 19 7

Remarks

※Material- standard JIS 20kg/cm²g steel

※Thickness must be equal to the standard or larger

Table 2.2 Flange dimensions

Note:

1. Please weld steel pipes onto flanges by butt-welding and make sure debris has been cleaned,

otherwise the compressor might be damaged during running. Flow velocity in the discharge

side of the compressor could be as high as 15~20 m/sec. High-speed discharge gas will

make noise in discharge connection. In order to decrease the noise level, it’s recommended

to round sharp edges of joints of piping as shown in Figure 2.4

2. The discharge and suction piping is recommended to be one size larger to reduce pressure

drop and noise level. If the noise level is high in discharge side, it is suggested to increase

the piping thickness or enclose with acoustic foam shown in Figure 2.5.

Loading...

Loading...