Hansa C16 O&M Manual - OM-009 Revision G 26/09/2019

© Hansa Chippers 2019

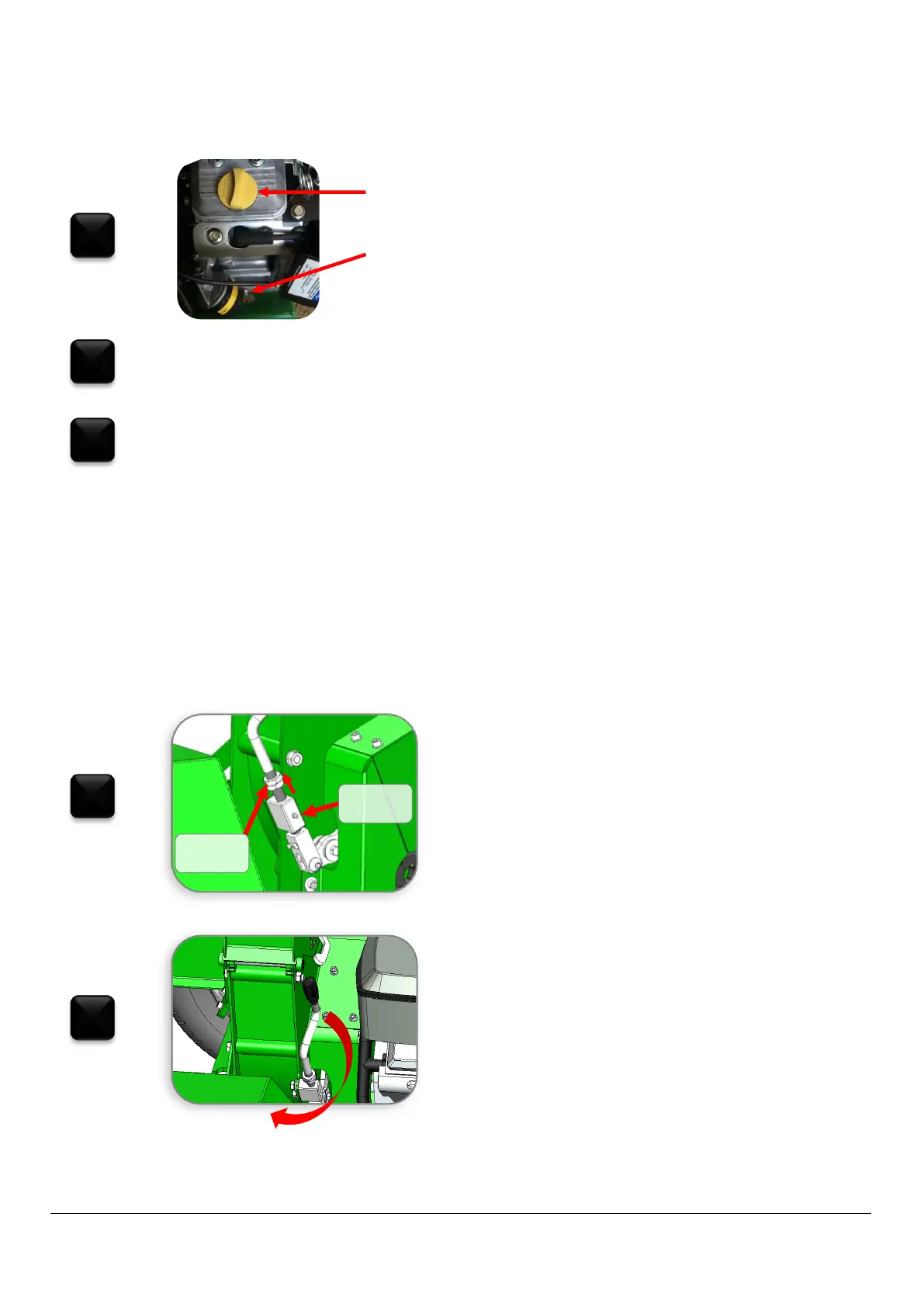

If the engine oil needs to be changed, follow these steps:

Run the engine for 1-2 minutes in order to warm up the

oil. Switch the engine off after the oil is warm. Place a

container underneath the engine. Remove oil filler cap

and oil drain plug (using a 10 mm spanner), then let the

oil drain into the container through the opening in the

chassis.

Screw the oil outlet drain plug back in and fill the engine with 1.4 litres of SAE 10W30 or SAE 10W40 through the

oil filler cap.

Recheck the oil level. It should be close to, but not above, the upper limit indicator on the dipstick. Screw the oil

filler cap back on. Dispose of the used engine oil in an environmentally sensitive way.

Belt tension

Correct belt tension is crucial for minimising belt wear and maximising machine efficiency. To check the belt tension, first ensure

the belt drive is disengaged by turning the engagement handle anticlockwise. Then, from the fully disengaged position, gently turn

the engagement handle clockwise until you feel it start to resist. From this position, turn the engagement handle clockwise. If the

tension is set correctly, the handle should turn one full revolution clockwise before coming to a stop. If there is a difference greater

than 1/6 of a revolution either clockwise or anticlockwise from one full revolution, then the belt tension should be corrected

following the ‘adjusting belt tension’ procedure.

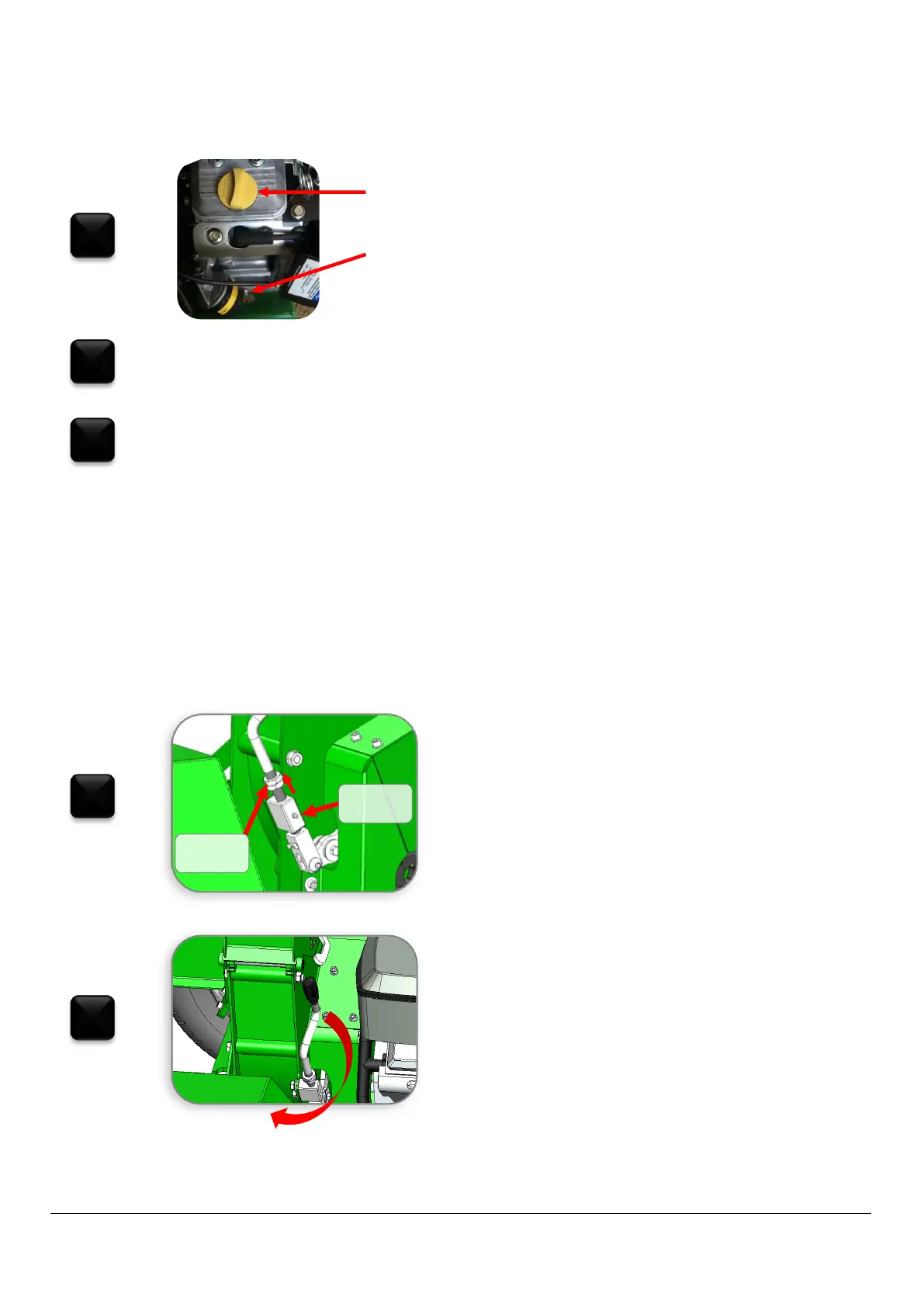

Using two 24 mm spanners, unlock the two locking nuts from

above the adjustment block on the engagement handle by

turning the top nut anti clockwise and the bottom nut

clockwise. Then move both locking nuts upward along the

thread.

From the fully disengaged position, gently turn the

engagement handle clockwise until you feel it start to resist.

From this position, turn the engagement handle one full

revolution clockwise. This is the recommended tension for the

belt drive when in the fully engaged position.

Loading...

Loading...