6 - Maintenance

107

Occasional Maintenance

General Info

The maintenance and service intervals for the following components will depend very much on the conditions under which

the sprayer is operated, and therefore it is almost impossible to specify the intervals beforehand.

The operator must select appropriate intervals for the occasional maintenance.

If in doubt, contact your local HARDI dealer.

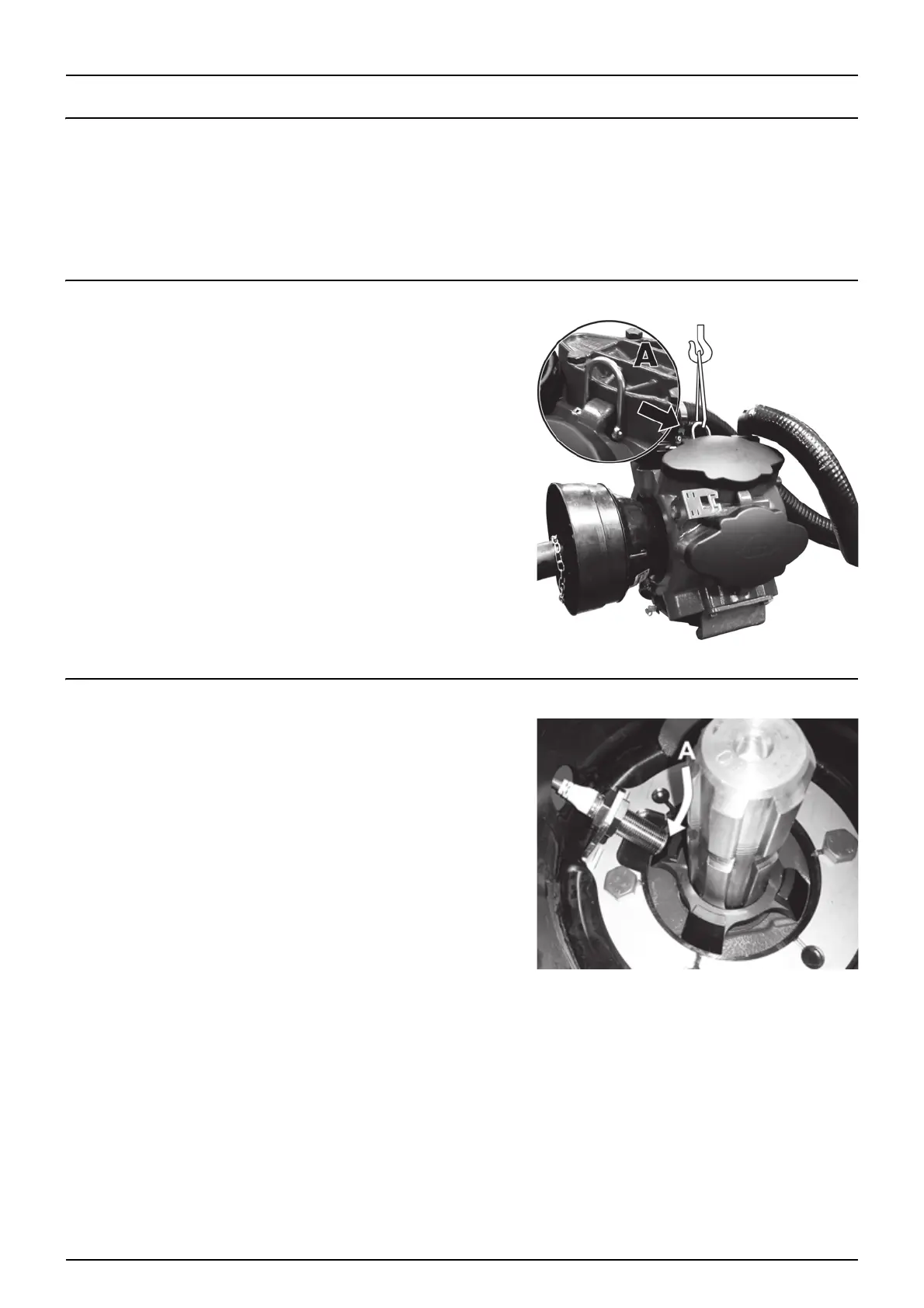

Lifting and Removing the Pump

When lifting and removing the pump, use a shackle fitted to the built-in

lifting eye located between the heads (A).

±

WARNING! To prevent damages in case of a free-falling pump, use

lifting gear and a steel shackle with at least 3.5 tonnes max. tensile

strength.

÷

NOTE! Pump weight is approximately 75 kg.

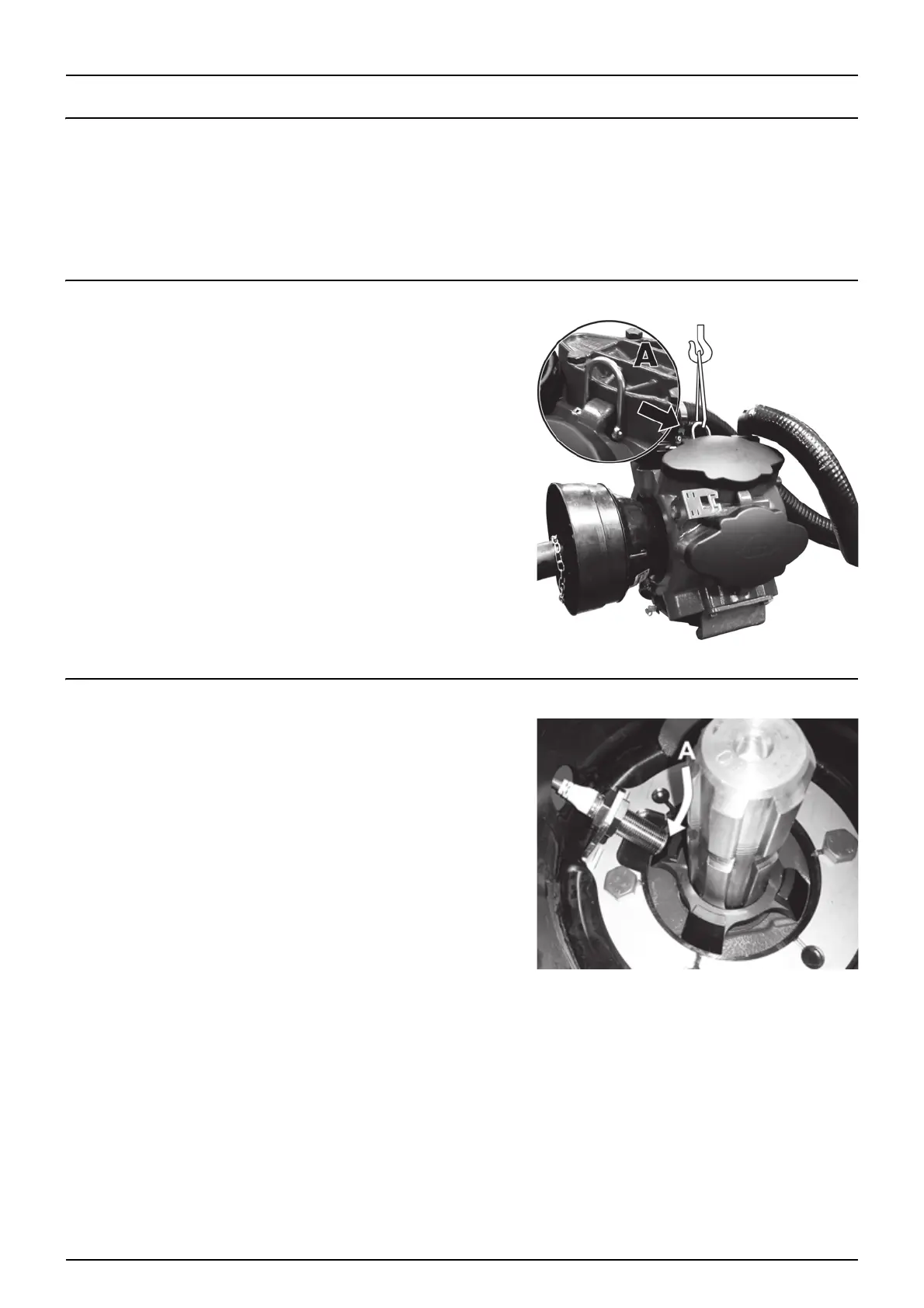

Speed Transducer for the Pump

The speed transducer that measures rotations per minute (RPM), is

located at the inner side of the PTO shield.

The sensor is an inductive type, which requires metallic protrusions to

pass by it to trigger a signal.

If the sensor is exchanged, it must installed accurately to function

properly.

Adjustment

1. Adjust the air gap (A) between sensor tip and the protruding

pump part by turning the counter nuts at the support bracket for

the sensor.

The air gap (A) must be set to 1 mm (+0.3/-0.0 mm).

Use a feeler gauge or similar tool to verify.

2. Verify transducer function on the controller:

• HC 5500:

Correct fitting is indicated by continuous flashing from transducer, when the shaft is rotating.

Loading...

Loading...