4 - Sprayer Setup

66

Hydraulic Systems

General Info

Ensure that the snap couplers are clean before connection! Failure to do so will cause premature wear to the hydraulic

system.

After having operated the boom, and the system has been filled with oil, check the tractor’s hydraulic oil level, and top up if

necessary.

€

DANGER! Test of the hydraulic system should be done very cautiously. There may be air trapped in the system which

can cause violent movements of the boom.

€

DANGER! Hydraulic leaks: Never use your fingers to locate a leakage in any part of the hydraulic system. Due to high

pressure, hydraulic oil may penetrate the skin.

Tractor Requirements

The hydraulic system requires:

Y model

• One single-acting outlet to raise and lower the boom.

• One double-acting outlet to fold and unfold the boom.

• One double-acting outlet for hydraulic slanting control (Y option).

Z model

• One double-acting outlet for the electro-hydraulic operation of the boom functions.

Models without electrical activated boom lift also require:

• One single-acting outlet to raise and lower the boom.

÷

NOTE! The hydraulic hoses are marked with arrows to indicate the direction of oil flow.

μ

ATTENTION! The hydraulic system requires an oil flow between 25 and 130 l/min and a minimum pressure of 180

bar.

±

WARNING! All hoses MUST be connected. Ensure snap couplers are completely clean before connecting. Failure to do

so will cause premature wear to the hydraulic system.

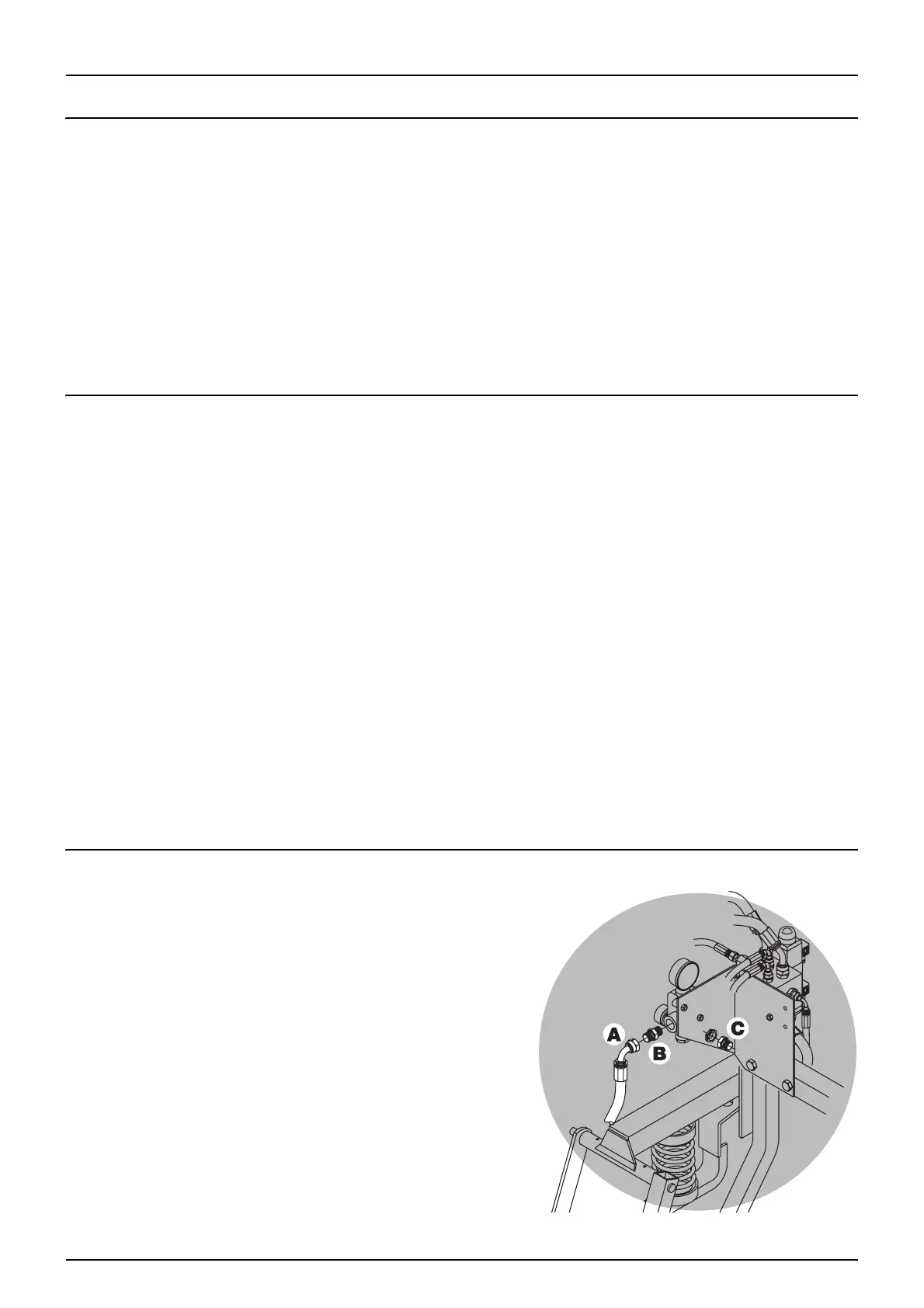

Closed Centre Hydraulics (AirStream only)

The sprayer is delivered for use with open centre hydraulic systems. If the

tractor is equipped with closed centre (load sensing) hydraulics, the

bypass on the hydraulic valve block on the sprayer needs to be blocked

off.

The sprayer is supplied

with an extra 1/2” brass nipple with no

perforation.

To convert the sprayer for closed centre hydraulics:

1. Disconnect hydraulic hose A

2. Swap standard 1/2” black nipple B with brass nipple C

3. Connect hydraulic hose A.

Loading...

Loading...