72 1018854 12/2015 V01

5.3 Mechanical Installation

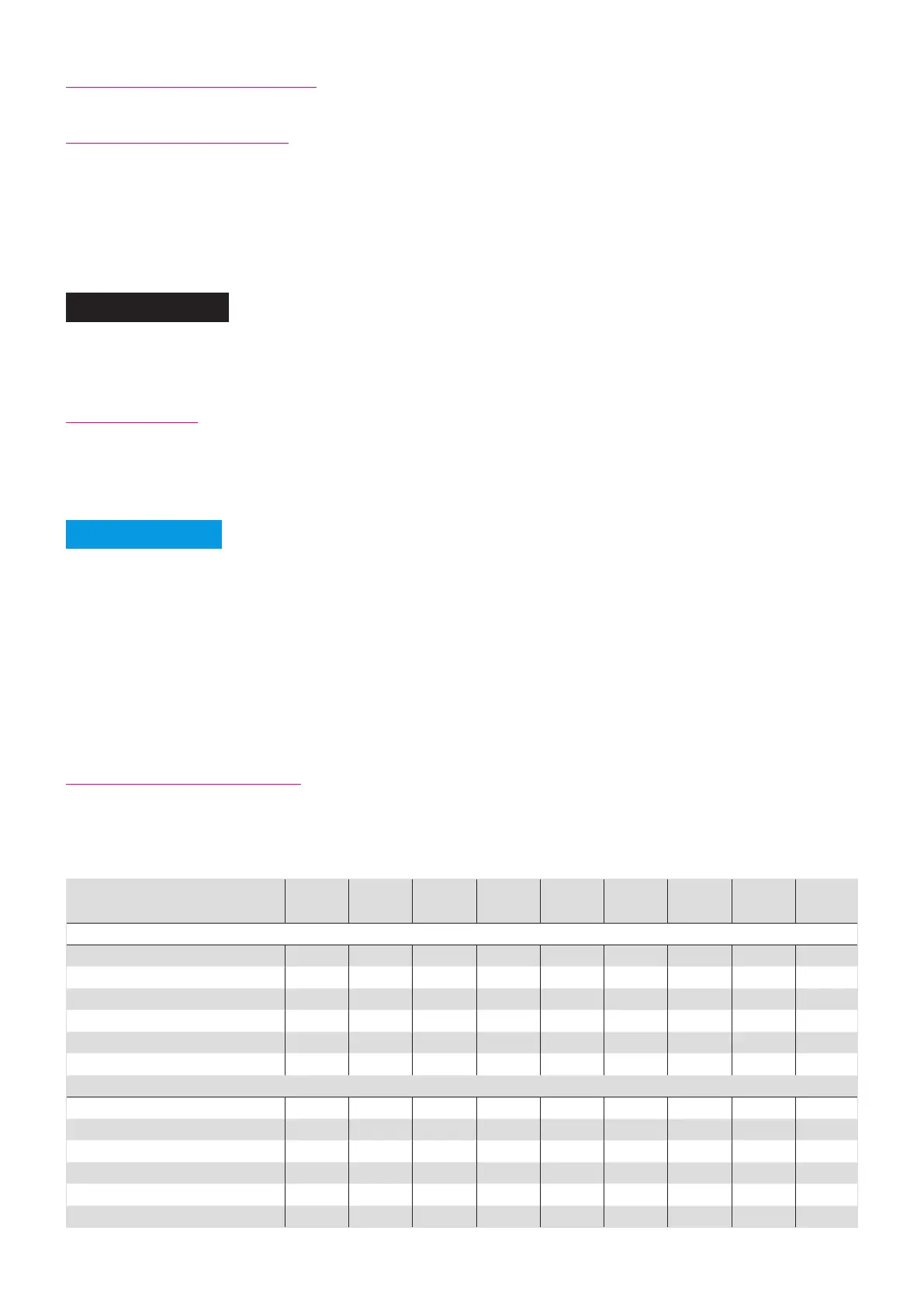

The data necessary for mounting the actuator and for connecting to the load are given in table 45.1.

Symbol

[Unit]

CHA-14A CHA-17A CHA-20A CHA-25A CHA-32A CHA-40A CHA-50A CHA-58A

Load assembly

Number of screws 12 12 12 12 12 12 12 12

Screw size M3 M4 M4 M5 M6 M8 M10 M10

Screw quality 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9

Pitch circle diameter [mm] 43 52 62 76 96 118 152 175

Screw tightening torque [Nm] 2.3 5.1 5.1 10 17 42 83 83

Transmittable torque [Nm] 85 188 228 463 847 1964 4086 4688

Housing assembly

Number of screws 8 12 12 12 12 12 12 12

Screw size M3 M3 M3 M4 M5 M6 M8 M10

Screw quality 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9

Pitch circle diameter [mm] 68 80 89 105 135 168 206 236

Screw tightening torque [Nm] 2.3 2.3 2.3 5.1 10 17 42.2 83

Transmittable torque [Nm] 89 158 177 378 805 1482 3419 6317

Data valid for completely degreased connecting interfaces (friction coecient µ = 0.15). Screws to be secured against loosening. We recommend LOCTITE 243 to secure screws.

Table 72.1

5. Installation and Operation

5.1 Transport and Storage

The transportation of the servo actuators and motors should always be in the original packaging.

If the servo actuators and motors are not put into operation immediately after delivery, they should be stored in a dry, dust

and vibration-free environment. Storage should be for no longer than 2 years at room temperatures (between +5° C ... +40° C)

so that the grease life is preserved.

Tensile forces in the connecting cable must be avoided.

5.2 Installation

Check the performance and protection and check the suitability of the conditions at the installation site. Take suitable con-

structive measures to ensure that no liquid (water, drilling emulsion, coolant) can penetrate the output bearing or encoder

housing.

The installation must be protected against impact and pressure on the gear.

The mounting must be such that heat loss can be adequately dissipated.

No radial forces and axial forces may act to the protection sleeve of the hollow shaft actuator.

During installation, the actuator must be fitted ensuring the machine housing can be rotated without terminals. Already low

terminals may aect the accuracy of the gear and, should this be the case, the installation of the machine housing should be

checked.

INFORMATION

ADVICE

Loading...

Loading...