C 08 Order No. BA 92-20-262 Issue 01.03.08 27

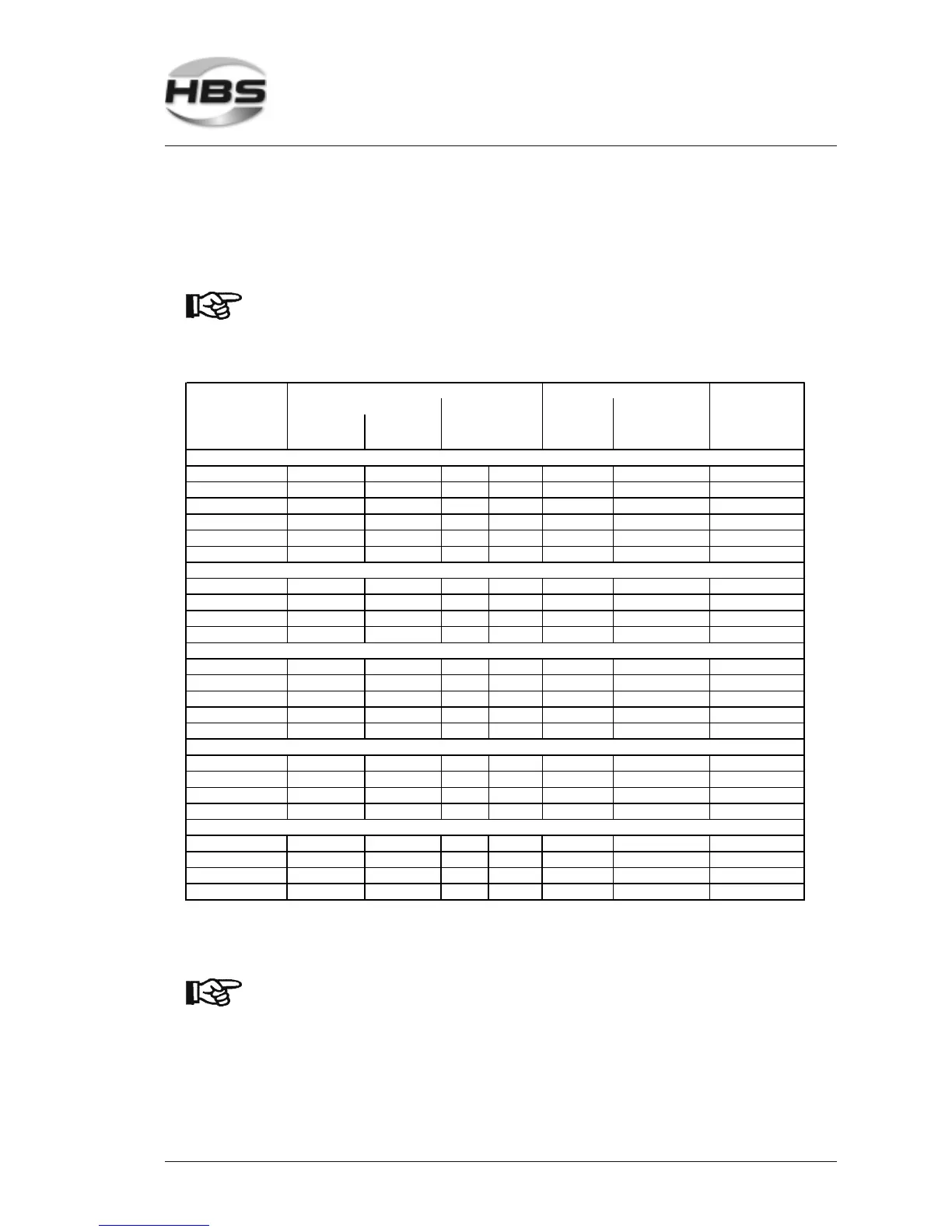

Example:

welding parameters for welding gun C 08 in connection with power

unit CD 1501

Data given in the following table are only guidelines. They

must be verified by trial welds on the actual material

according to actual standards and DVS guidelines (see

appendix). Before you use another lot of welding elements,

carry out some trial welds to verify the parameter setting.

Material of Gun parameters

welding elements CD 1500 CD 1501 C 08

PT, UT IT

Adjustment

(scaling)

Charging voltage

(V)

Spring force

(scaling)

S235 / St37 (4.8) M3, 3 mm -- 1/8" #6-32 3 70 6

S235 / St37 (4.8) M4, 4 mm -- 5/32" #8-32 4 90 6

S235 / St37 (4.8) M5, 5 mm 5 mm, M3 3/16" #10-32 5 120 6

S235 / St37 (4.8) M6, 6 mm 6 mm, M4 1/4" 1/4-20 6 140 6

S235 / St37 (4.8) M8, 7,1 mm 7,1 mm, M5 5/16" 5/16-18 8 190 6

S235 / St37 (4.8) M10, -- 7,1 mm, M5 3/8" 3/8-16"

1) 1)

6

S235 M3, 3 mm -- 1/8" #6-32 4 90 6

S235 M4, 4 mm -- 5/32" #8-32 5 120 6

S235 M5, 5 mm -- 3/16" #10-32 7 160 6

S235 M6, 6 mm -- 1/4" 1/4-20 9 200 6

1.4301, 1.4303 M3, 3 mm -- 1/8" #6-32 2 60 6

1.4301, 1.4303 M4, 4 mm -- 5/32" #8-32 3 70 6

1.4301, 1.4303 M5, 5 mm -- 3/16" #10-32 4,5 100 6

1.4301, 1.4303 M6, 6 mm -- 1/4" 1/4-20 6 140 6

1.4301, 1.4303 M8, 7,1 mm -- 5/16" 5/16-18 8 190 6

CuZn37 M3, 3 mm -- 1/8" #6-32 2 60 6

CuZn37 M4, 4 mm -- 5/32" #8-32 3,5 80 6

CuZn37 M5, 5 mm -- 3/16" #10-32 5 120 9

CuZn37 M6, 6 mm -- 1/4" 1/4-20 6,5 150 9

AlMg3 M3, 3 mm -- 1/8" #6-32

2) 2) 2)

AlMg3 M4, 4 mm -- 5/32" #8-32

2) 2) 2)

AlMg3 M5, 5 mm -- 3/16" #10-32

2) 2) 2)

AlMg3 M6, 6 mm -- 1/4" 1/4-20

2) 2) 2)

Material of workpiece: Cr-Ni stainless steel 1.4301, 1.4303

Material of workpiece: Brass CuZn37

Material of workpiece: Aluminum

Energy

Material of workpiece: Mild steel, shiny S235 / St37.3k (4.8) weldable

Material of workpiece: Steel galvanized S235

(metric)

Diameter of welding elements

(imperial)

1)

power unit with higher capacity recommended

2)

not possible. For a safe aluminum weld we recommend welding gun CA 08.

Further notes on

– welding elements

– prestress at installation (tie load) and torque

– material combinations

see appendix and operating manual of the according power

unit.

5 Stud Welding Procedure

5.5 Determination of Welding Parameters

Loading...

Loading...