45©HBS Bolzenschweiss-Systeme GmbH & Co. KG

All rights reserved – Reprinting, in whole or in part, only with the approval of the manufacturer

13 Checking the Quality of the Weld

You don’t need to test all studs.

It is sufcient to carry out stud tests on several production samples that are

picked at random.

Bending Test

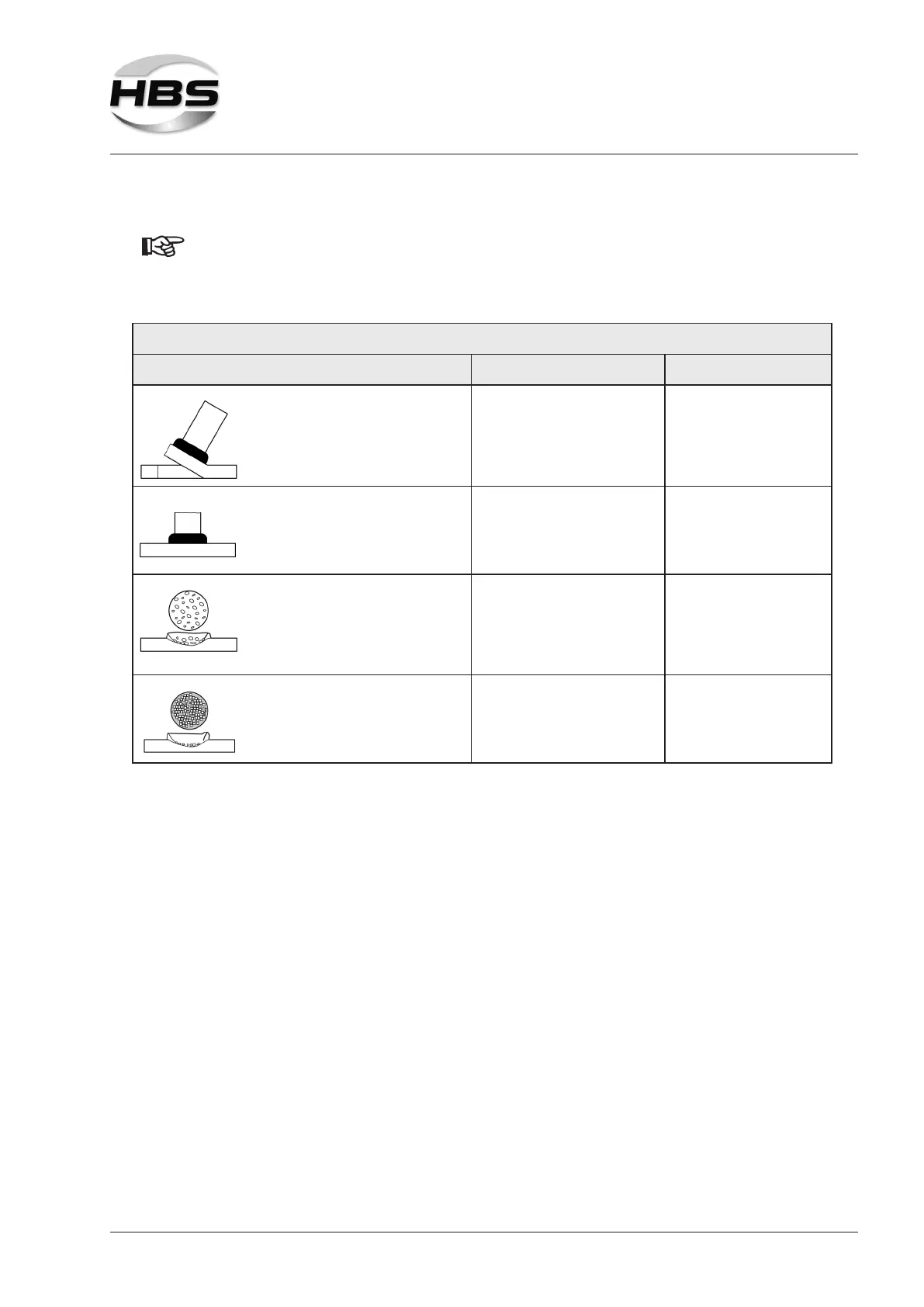

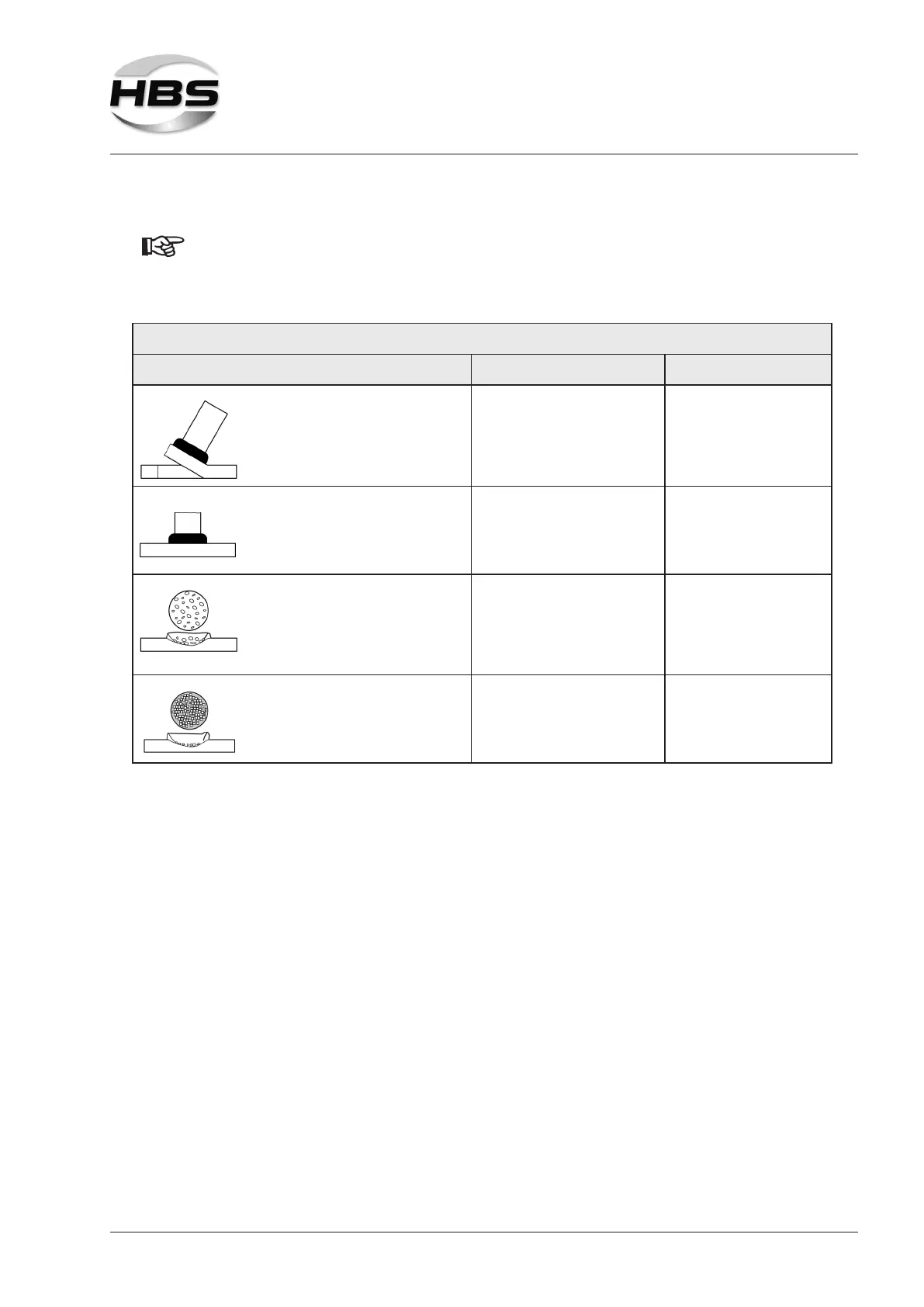

Type of fracture Possible cause Corrective actions

Tearing of parent material Correct parameters none

Fracture above collar after sufcient

deformation

Correct parameters none

Fracture within the weld.

High porosity

Weld energy too low Increase current and/or

welding time

Unclean surface Clean the surface

Material not suitable for stud

welding

Select suitable material

Fracture of weld

Bright appearance

Welding time too low. Increase welding time

If the strength of the joint is inadequate, then:

check the setting of the stud welding unit.

check whether the surface of welding element and base material are clean and

electrically conductive.

They must be free from scale, oil, paint, oxide layers.

Grind off hardened workpiece surfaces (e.g. roll hardening).

Check the piston of the welding gun for ease of movement.

Loading...

Loading...