Users Manual Henkovac 04-serie V2019

10.6 Sealing

The synthetic packaging material is melted shut by a heated sealing wire.

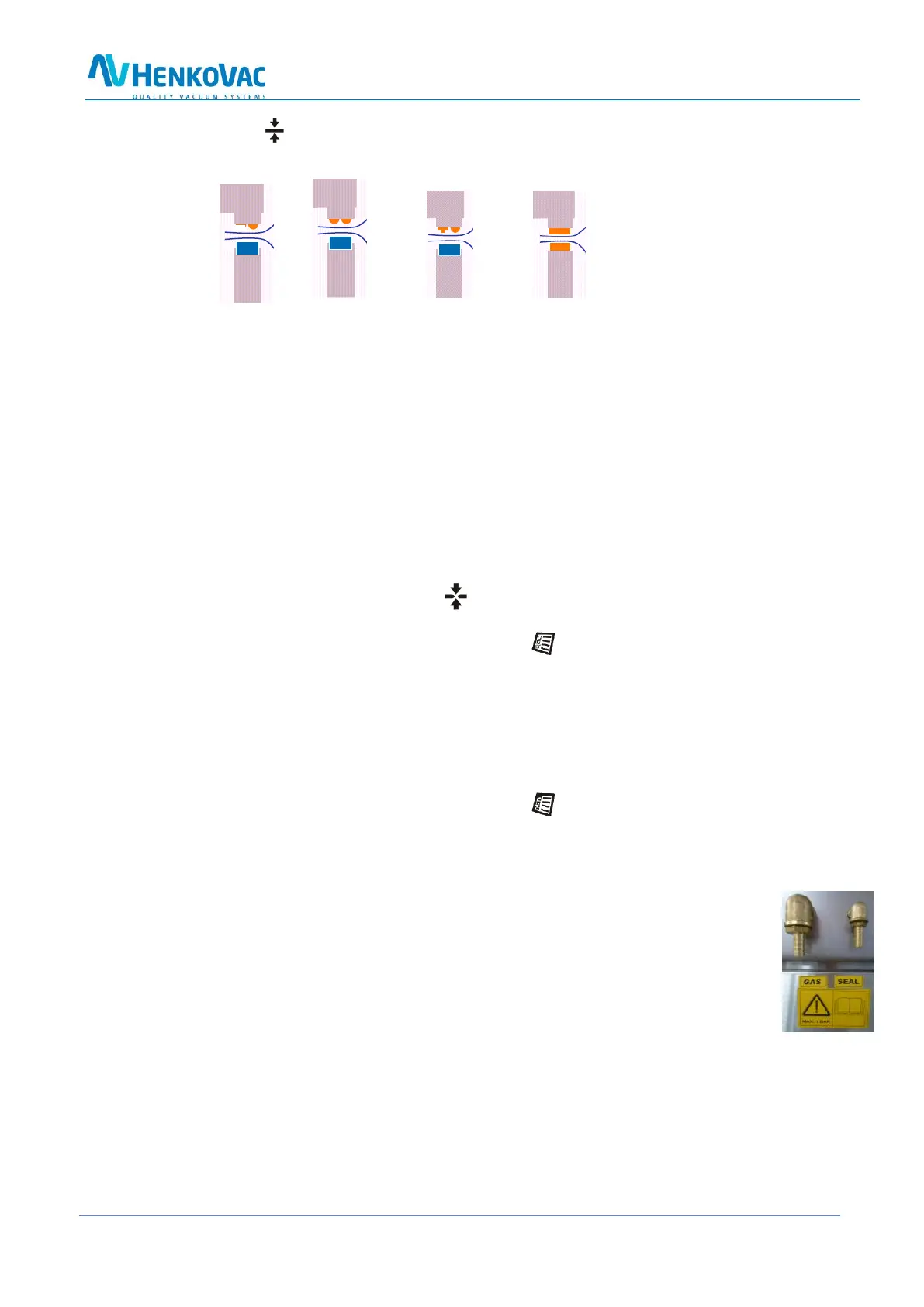

single seal double seal clean cut & two-sided seal

clean cut controlled

Single Seal

Only for T2. The package is sealed with a single sealing wire

Double Seal

All other machines are equipped with a double sealing wire

Clean Cut Seal (CC Seal)

One of the two heated wires is used to score the package. This makes it easy to remove the

excess packaging material. The package has one seal and a nicely trimmed edge.

Clean Cut Controlled Seal (CCC Seal)

o Only for Ten-Program machines with sensor-based control

o Can be turned on or off in the Settings menu

Identical to the Clean Cut seal, with the only difference that the heating time for the scoring wire

can be programmed independently. This improves control over the scoring process. Typically used

for shrink bags.

Two-Sided Seal

o Only for Ten-Program machines with sensor-based control

o Can be turned on or off in the Settings menu

The counter beam contains a sealing wire as well. Used for thick material or metallic packaging

materials, requiring additional heat to seal the bags.

10.7 Extra Sealing Pressure

During the sealing process, the package is held in place between the seal beam and

the counter beam. To assure a proper package seal, additional air pressure to the sealing

beam may be beneficial (maximum of 1 bar), for instance during MAP gassing

above 500 mbar.

The M4-M8 and the D1-D6 models with the option Gas/MAP are standard equipped

with a compressed air inlet. Otherwise it can be easily retrofitted.

Extra sealing pressure is not necessary and not available for the Table-Top, M1, M2, M3

Loading...

Loading...