Users Manual Henkovac 04-serie V2019

12.0 Malfunctions and Notifications

In case the machine has technical problems, please use the check list below to see if you can resolve

the malfunction yourself

If technical support is required, please contact your dealer

You may also contact us, so that we can assist you in locating your nearest dealer

+31 73 627 12 73 of 77 or by e-mail info@henkovac.com.

12.1 Service and Technical Support

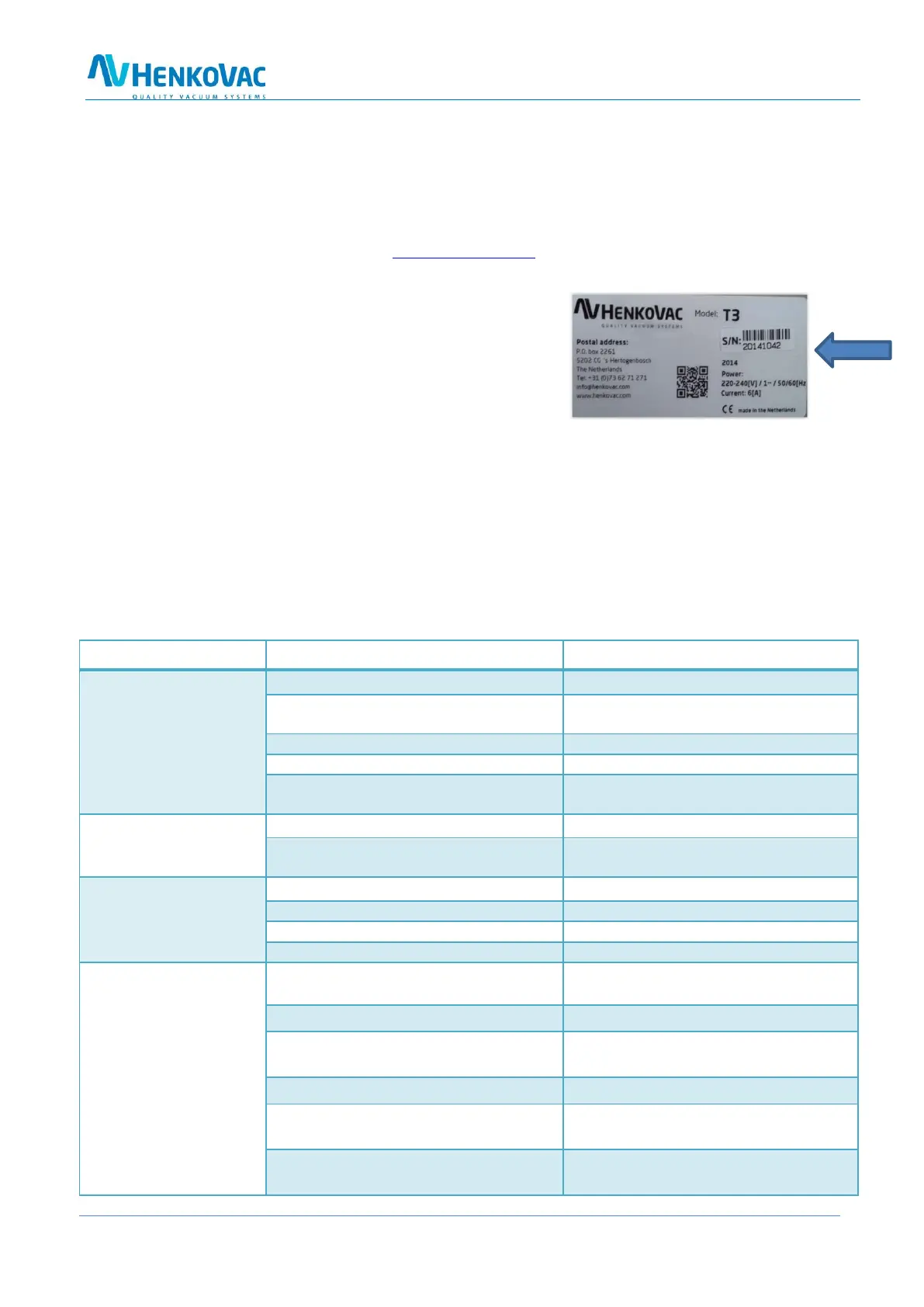

Please have the following information available:

Machine type

Serial number

You can locate this information on the identification plate

on the right-hand side or back-side of your machine.

12.2 YouTube Henkovac Channel - Instruction and Service Videos

Instructional videos are placed on YouTube for the operation and service of your machine. You may lo-

cate these videos on the YouTube website under “Henkovac Channel”.

12.3 Trouble Shooting Check List

The machine is not plugged in

Plug the machine into the electrical outlet

The ground fault safety in the electrical

panel has tripped

Check the electrical panel

A fuse in the electrical panel is faulty

Check the electrical panel

A fuse in the machine is faulty

The motor protection of the machine is

switched off

The vacuum pump does

not run at full speed

The oil is too thick or contaminated

Change the oil. Page20: 10.2

The pump motor runs on two phases

Check the voltage; if correct, consult your

dealer

The vacuum in the pack-

age is insufficient

The programmed vacuum value is too high

Lower the vacuum value in the program

The packaging material is of poor quality

Select a better-quality packaging material

The product damages the bag

Program a higher value for Soft-Air

The machine gases the package

Turn off the gassing function

The package seam is poorly formed

Increase the sealing time and/or reduce the

MAP gas pressure

The package seam is burnt

Decrease the sealing time

The opening of the vacuum bag is contami-

nated

Try again and make sure that the opening

of the bag stays clean

The sealing beam is dirty

The Teflon lining of the sealing beam is

damaged

Replace the Teflon lining

The silicon rubber seal in the counter beam

is damaged

Replace the silicon rubber seal

Loading...

Loading...