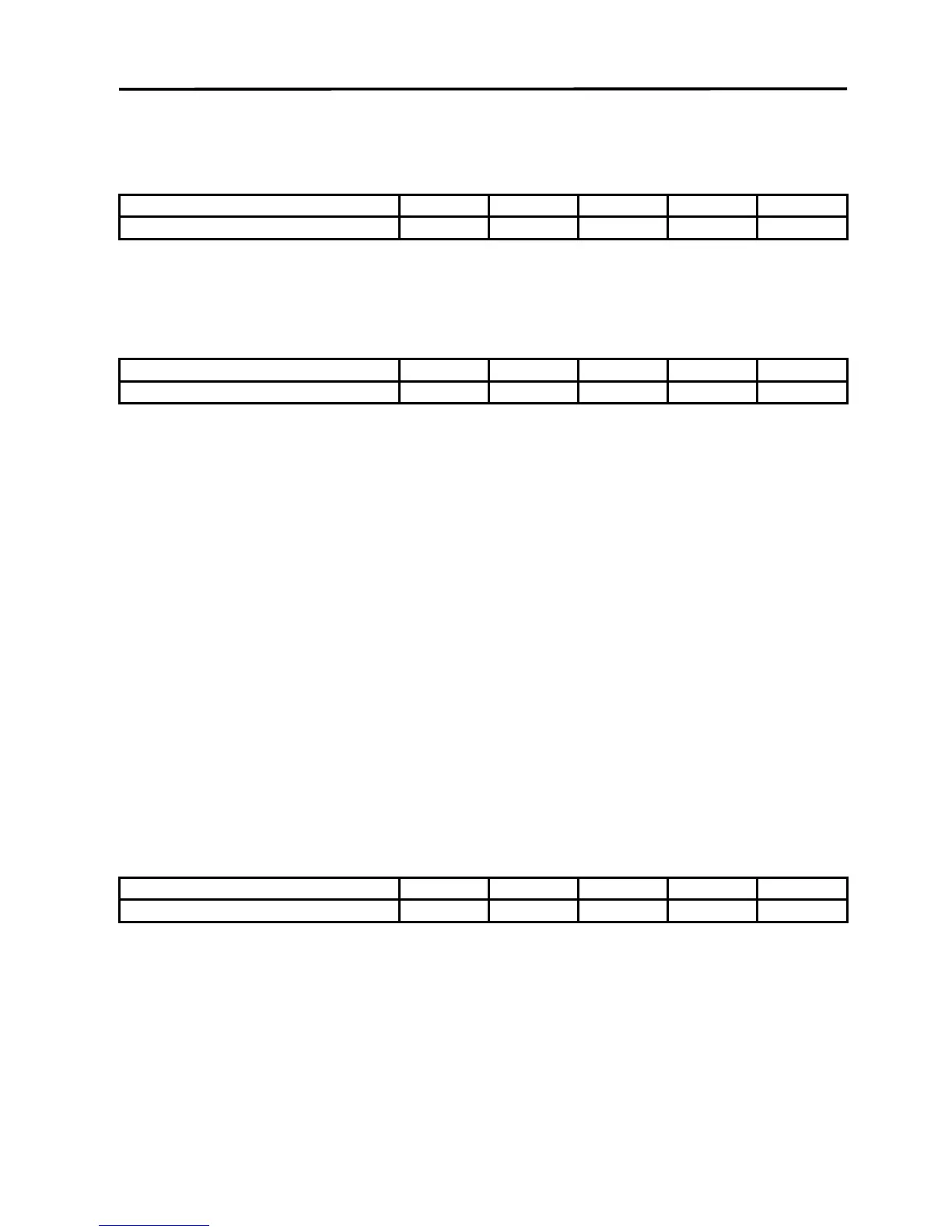

COMMENTS: Again, since glass will not vaporize, it does not require much laser power.

ADDITIONAL COMMENTS

Glass engraving is different from other types of engraving. A CO

2

laser cannot engrave into the

glass nor can it cut glass. Instead, laser interaction with glass causes the surface of the glass

to appear frosted. Sometimes, placing a piece of newspaper on the glass and dampening is

with water will improve the appearance of the engraving. Another method is to apply transfer

tape to the glass, wet it with water from a spray bottle, and laser engrave it. The transfer tape

and water will act as a heat sink and pull the heat away from the glass as the laser system

engraves it. This helps reduce chipping or flaking of the glass.

Be especially careful when engraving leaded crystal. The lead in crystal conduct heat which

can cause much more flaking or even the cracking of the crystal. Use a lower power setting to

try to reduce the chance of damage. It is always good to have at least one extra piece to use as

a test piece to get the right settings especially if you have never tried to engrave that material

before.

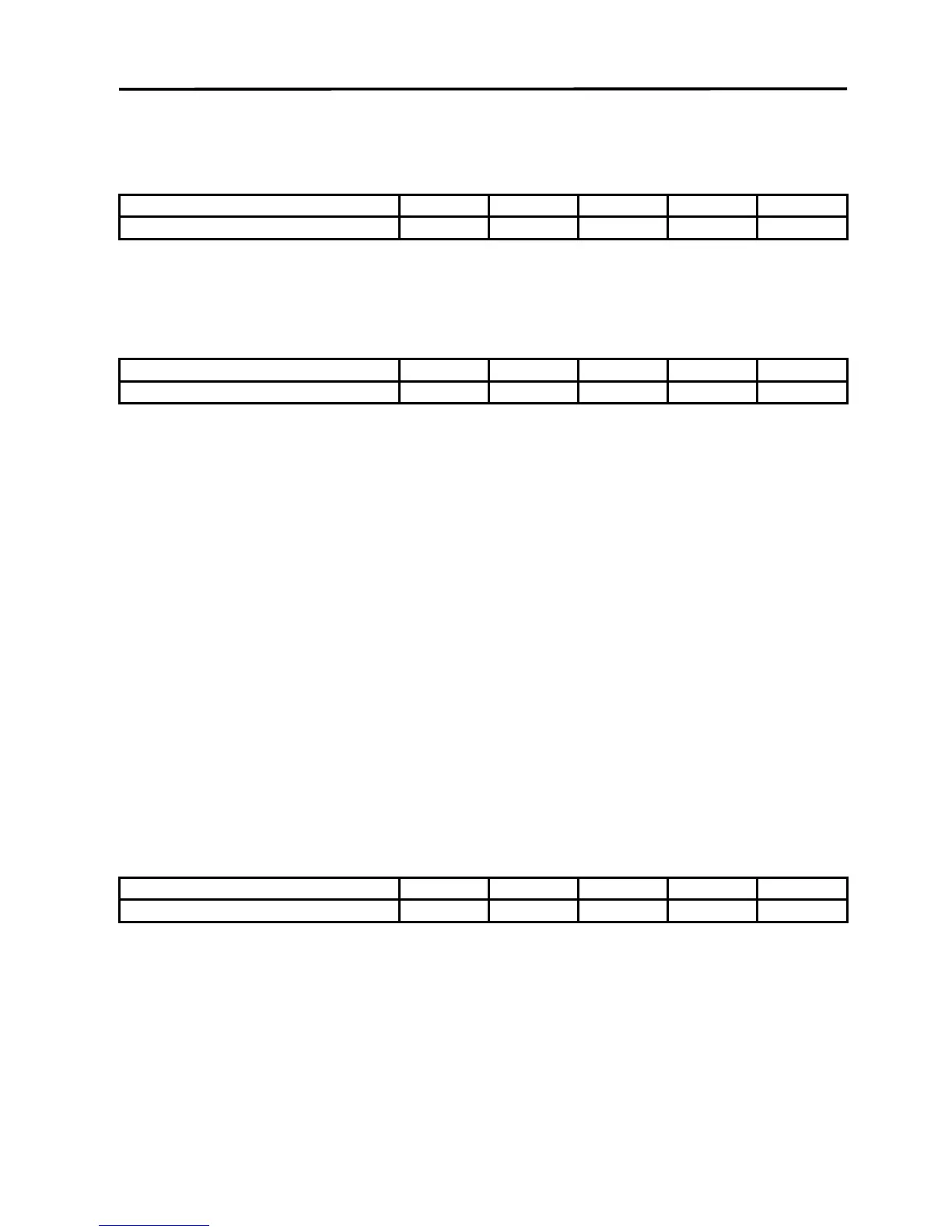

If using the optional Rotary Fixture in the Portrait Mode use the following settings to minimize

the chances of the object slipping in the fixture while running at high speeds. If engraving in the

landscape mode, use the settings defined at the top of this page.

Loading...

Loading...