Do you have a question about the Hitachi NV45AB2 and is the answer not in the manual?

Defines DANGER, WARNING, CAUTION, NOTE signal words used in the manual.

Provides essential safety rules for operating nailers.

Requires safety glasses with side shields for all personnel in the work area.

Bans oxygen or bottled gases as a power source due to explosion risk.

Directs users not to point the nailer at themselves or others.

Advises keeping fingers off the trigger to prevent accidental firing.

Warns against exceeding the maximum recommended air pressure of 120 psi.

Recommends wearing ear and head protection during operation.

Emphasizes clean work areas and keeping visitors away.

Prohibits use near flammable liquids or gases due to sparking.

Recommends appropriate clothing and footwear for safe operation.

Warns against placing hands or feet near the firing head during use.

Addresses risks like double fire, ricochets, and firing into vulnerable areas.

Covers avoiding overreaching, carrying by hose, and using defective tools.

Lists conditions requiring air hose disconnection from the nailer.

Advises staying alert and handling the nailer correctly per manual.

Restricts nailer use to specified applications and prohibits modification.

Mandates using only genuine Hitachi parts and accessories.

Safety instructions for NV45AB2, including nail guide usage and cleaning fluids.

Safety instructions for NV45AB2(S), including nail guide and magazine loading.

Outlines employer responsibilities for safety, manuals, and tool maintenance.

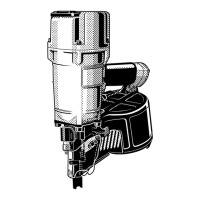

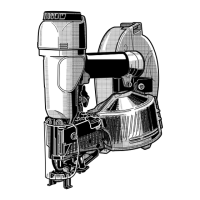

Identifies and labels the different parts of the nailer.

Provides technical details for NV45AB2 and NV45AB2(S) models.

Details the types and sizes of nails compatible with the nailer.

Lists standard and optional accessories for the nailer.

Describes the intended uses for the nailer.

Outlines essential checks and preparations before operating the nailer.

Details requirements for a safe and suitable working environment.

Explains compressed air source, FRL units, air hose, and consumption.

Explains the importance and method of lubricating the nailer.

Offers guidance on operating the nailer in cold weather conditions.

Guides on disconnecting air hose, removing nails, and checking screws.

Verifies smooth lever/trigger movement and no air leaks.

Sets test pressure and confirms nailer does not operate unintentionally.

Tests nailer response to push lever and trigger activation.

Confirms nailer operates correctly with nails loaded.

Guides on setting air pressure based on nails and workpiece material.

Safety precautions to follow when loading nails.

Explains how to adjust the nail holder for different nail lengths.

Instructs on placing the nail coil and preparing nails for driving.

Reiterates safety for glasses, pointing, trigger finger, and proximity.

Addresses risks like double fire, ricochets, and driving into vulnerable areas.

Highlights the significance of selecting the correct triggering method.

Details Intermittent (Trigger Fire) and Continuous (Push Lever Fire) operation.

Further details on push lever firing and nailer movement.

Warns about potential sparks from nails during firing.

Describes the use case and operation of the optional sequential trip mechanism.

Lists important steps like disconnecting air, removing nails, and lubricating.

Explains how to use the shingle guide for consistent spacing.

Guides on adjusting the depth at which nails are driven.

Essential safety steps before maintenance or jam clearing.

Step-by-step guide for clearing a jammed nail.

Instructions for inspecting and maintaining the nail feeder mechanism.

Verifies smooth operation of nail stoppers and lubricates surfaces.

Cleans tar and dirt, warning against flammable liquids.

Instructions for inspecting the magazine and guidance on proper storage.

Restricts repair work to trained and authorized personnel.

Mandates the use of genuine Hitachi parts for repairs.

Points to maintenance charts, troubleshooting guides, and parts lists.

Details routine maintenance actions, their purpose, and methods.

Addresses issues where the nailer functions but doesn't drive nails.

Solves problems related to reduced driving power or slow cycling.

Provides solutions for nails being driven too deep into the material.

Addresses issues of nails not feeding consistently or skipping.

Solves problems related to nails jamming or being driven bent.

Troubleshoots performance degradation at higher speeds.

Loading...

Loading...