15 of 20

Pump Start Relay Connection

L This controller does not provide mains power

to drive a pump–a pump must be driven via

an external relay and contactor setup.

L The controller provides a low voltage signal

that actuates the relay which in turn enables

the contactor and finally the pump

Although the controller has permanent memory and

thus a default program will not cause erroneous

valve actuation as in some controllers, it is still good

practice when using a system where the water

supply comes from a pump to connect unused

stations on the unit back to the last used station

This in effect, inhibits the chances of the

pump ever running against a closed head

Pump Protection (System Test)

L In some circumstances not all operational

stations may be hooked up–for example,

if the controller was capable of running 6

stations but there were only 4 field wires and

solenoid valves available for connection

This situation can pose a risk to a pump when the

system test routine for the controller is initiated

The system test routine sequences through

all available stations on the controller

In the above example this would mean stations

5 through to 6 would become active and would

cause the pump to operate against a closed head

This could possibly cause permanent

pump, pipe and pressure vessel damage

It is mandatory if the system test routine is going

to be used, that all unused, spare stations,

should be linked together and then looped to

the last working station with a valve on it

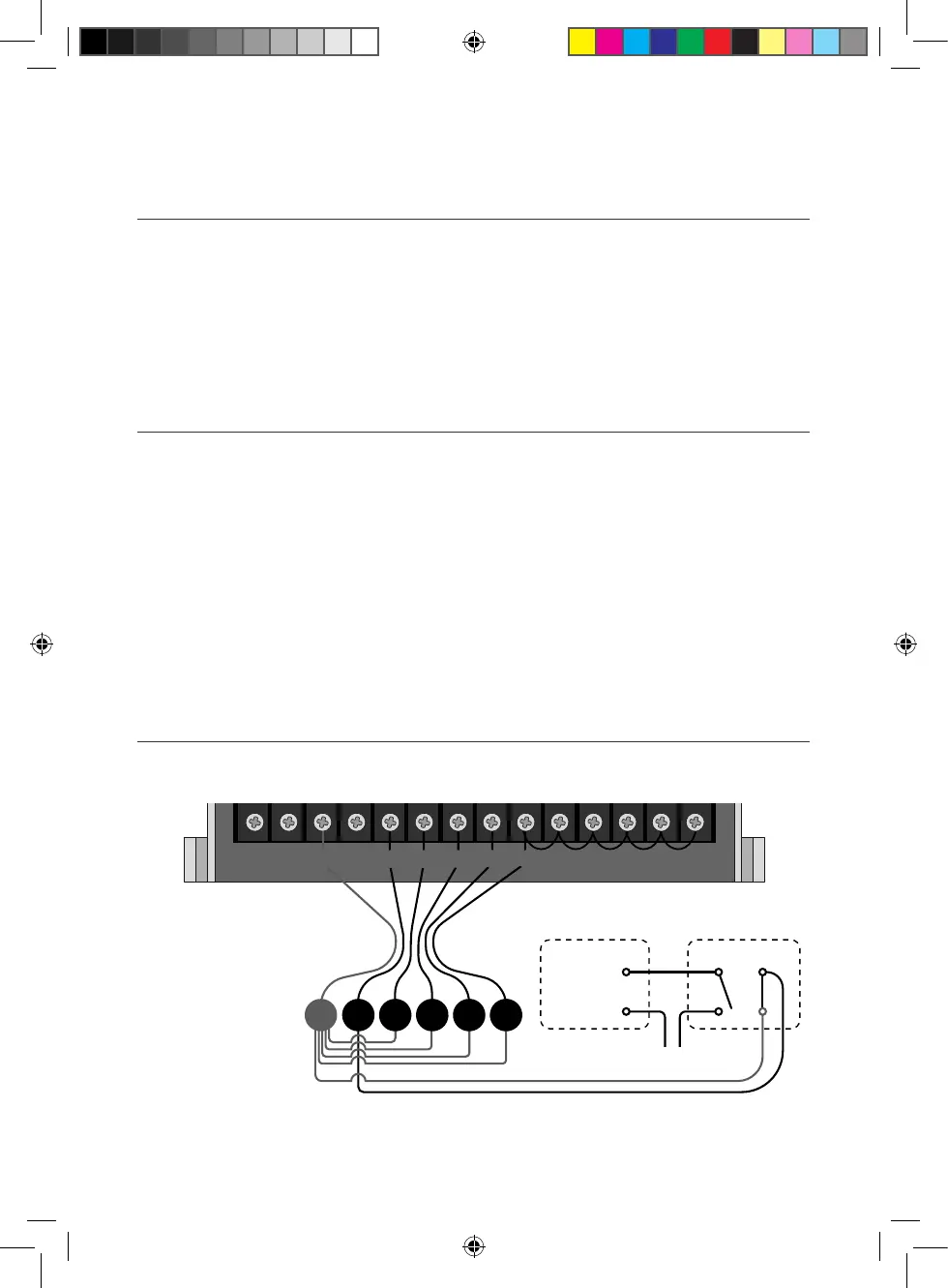

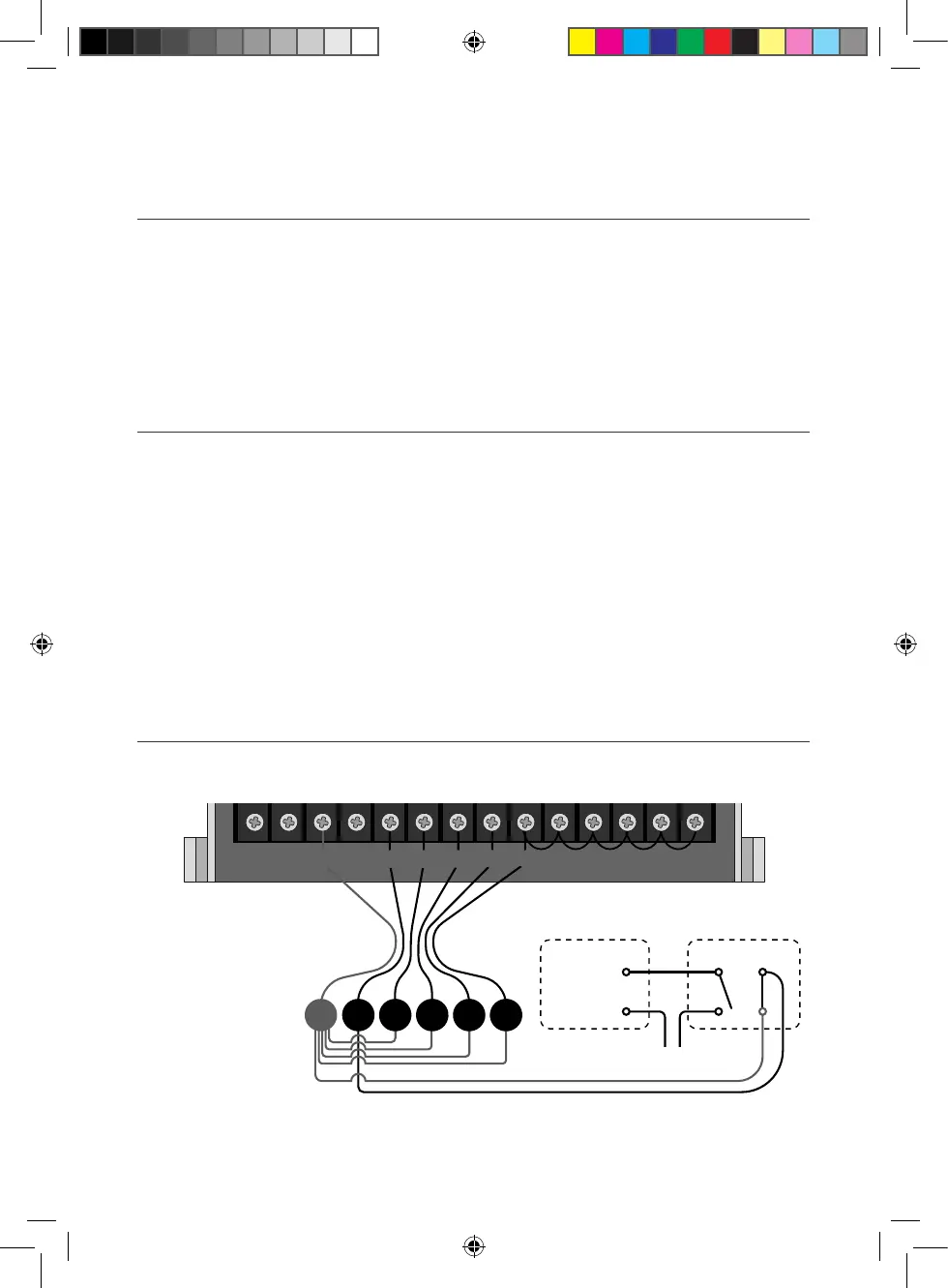

Using this example, the connector block

should be wired as per the diagram below

Single Phase Pump Installation

It is recommended to always use a relay between the controller and the pump starter

C 1 2 3 4

24VAC C R M 1 2 3 4 5 6 7 98

PUMP

MOTOR

MAGNETIC

STARTER

24VAC AC RELAY

POWER SUPPLY

M

Installation (continued)

PRO469 Manual 2021 v1.indd 15PRO469 Manual 2021 v1.indd 15 15/1/21 9:40 am15/1/21 9:40 am

Loading...

Loading...