ACCESSORI ES

HOLZMANN Maschinen Austria www.holzmann-maschinen.at

Seit e 3 7

Metalldrehmaschine / metal turning lathe ED 750 FDQ

1 6 .6 STEADY REST

The steady rest serves as a support for shafts on the free

tailstock end. For many operations the tailstock cannot be

used as it obstructs the turning tool or drilling tool, and

therefore, must be removed from the machine. The steady

rest, which function as an end support, ensures chatter-free

operation. The steady rest is mounted on the bedways and is

secured from below with a locking plate. The sliding fingers

require continuous lubrication at the contact points to prevent

premature wear. (Fig.20)

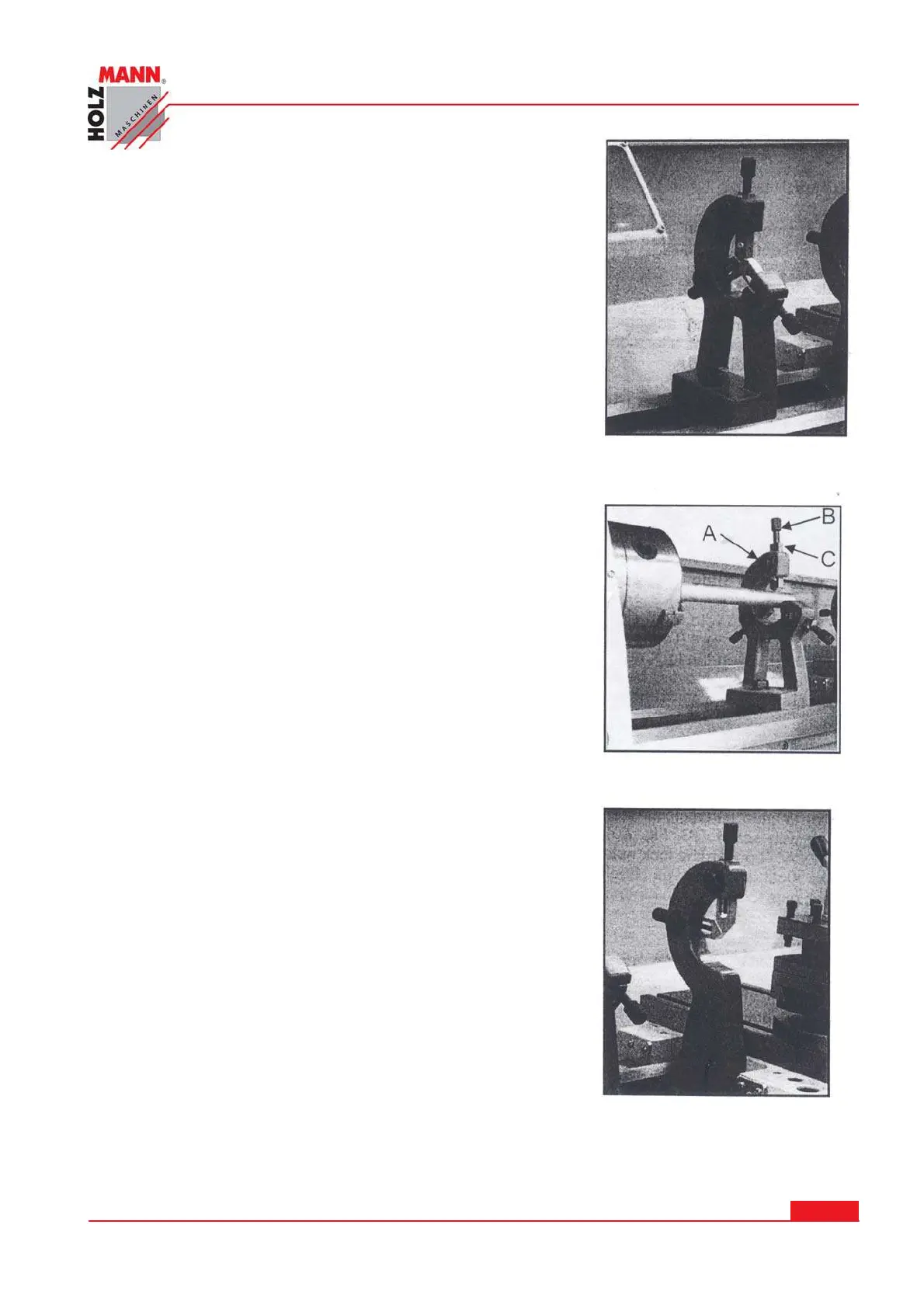

1 6 .7 SETTI NG THE STEADY REST

Loosen three hex nuts. (A,Fig.21)

Loosen knurled screw (B,Fig.21) and open the sliding fingers.

(C,Fig.21) until the steady rest can be moved with its finger

around the workpiece. Secure the steady rest in position.

Tighten knurled screws so that fingers are snug but not tight

against the workpiece. Tighten three nuts (A,Fig.21). Lubri-

cate the sliding points with machine oil.

When, after prolonged operation, the jaw show wear, the tips

of the fingers may be filed or remilled.

1 6 .8 FOLLOW REST

The follow rest is mounted on the saddle and follow the

movement of the turning tool. Only two sliding fingers are

required. The place of the third finger is taken by the turning

tool. The follow rest is used for turning operations on long,

slender workpieces. It prevents flexing of the workpiece un-

der pressure from the turning tool. (Fig.22)

Set the fingers snug to the workpiece but not overly tight.

Lubricate the fingers during operation to prevent premature

wear.

Fig.20

Fig.21

Fig.22

Loading...

Loading...