Setting up and connection

FKS 315-2000 E | Version 1.11 9

6.2 Scope of delivery

- Format sliding carriage with boom

- Material roll at the outrigger

- Saw blade 315x30x3mm 40 teeth

- Scoring saw blade 90x20x3mm 12 teeth

- Rip fence with round rod guide and fine adjustment

- Table extension

- Folding stop

- Trimming shoe

- Eccentric clamp

- Scoring device

- Saw blade protection hood with suction hose

7 Setting up and connection

7.1 Requirements for the installation

site

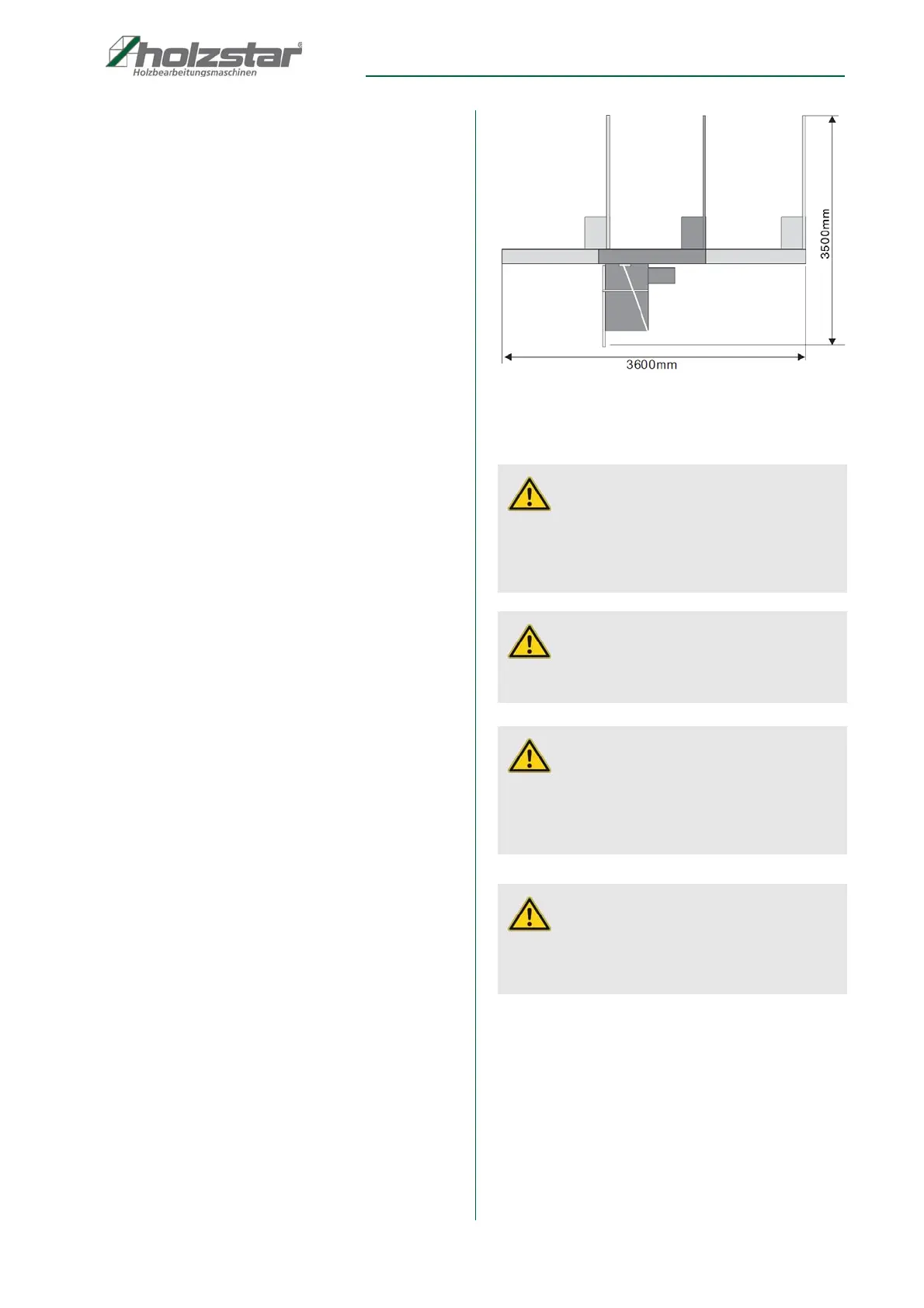

The panel saw must be set up stable on a level and firm

ground. It is important to ensure that there is enough

freedom of movement to work. The site should meet the

following criteria:

- The substrate must be level, firm and vibration-

free.

- Altitude of the workplace: max. 1000 m;

- Max ambient temperature: 40 ° C

- Min ambient temperature: 5 ° C

- Max humidity at 40 ° C: 50%:

- Max humidity at 20 ° C: 90%

- The substrate must not let any lubricant through.

- The installation or work area must be dry and well

ventilated.

- Do not operate machines that cause dust and

chips near the machine.

- There must be sufficient space for the operating

personnel, for material transport as well as for ad-

justment and maintenance work.

- The site must have good lighting.

- There must be a suction device with min. 690 m3 /

h extraction capacity, min. 20 m / s flow velocity at

the suction connection; Hose diameter 100 mm,

max. Hose length 4 m.

There must be a suct ion device with min. 690 m3 / h extraction capacity, min . 20 m / s flow velocity at the suc tion connection; Hose diameter 100 mm, max. Hose length 4 m.

Fig. 8: Space required at the workplace

7.2 Setting up the panel saw

Make the machine operational by following these steps:

Step 1: Remove the lid of the transport box and position

the fork of the truck above the machine.

Step 2: Attach four eyebolts to the machine base and at-

tach the risers to the eyebolts and over the

forklift fork. Use a wooden block to protect the

switch.

CAUTION!

Danger of injury due to a machine that is not stably er-

ected!

Check the stability of the machine after placing it on

stable ground.

CAUTION!

Some metal parts can be sharp-edged. Check all me-

tal parts to avoid injury.

CAUTION!

Pay attention to the weight of the machine!

The machine may only be set up by two persons.

Check the aid accordingly for sufficient dimensioning

and load capacity.

ATTENTION!

To ensure sufficient stability of the machine, it should

be screwed to the ground. There are 4 holes on the

machine housing for this purpose

Loading...

Loading...