Do you have a question about the Honeywell UDC 1000 Micro-Pro and is the answer not in the manual?

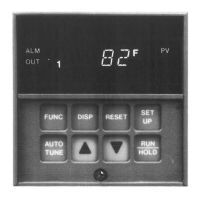

Overview of the Controller's normal day-to-day operating mode.

Describes the various displays that can appear in Operator Mode.

Details how to view and adjust the setpoint ramp rate parameters.

Explains how the alarm status is displayed when alarms are active.

Shows the displays for over-range and under-range conditions of the process variable.

Describes the display indication when a sensor break is detected.

Explains how to enter and operate the controller in Manual Control Mode.

Details how to use the Pre-Tune facility to set initial PID parameters.

Describes how to activate and use the Self-Tune facility for optimizing tuning.

Explains how to view the controller's hardware definition code.

Instructions for unpacking the controller and checking for damage.

Guidance on how to panel-mount the UDC 1000 Controller.

Details on the controller's rear terminal connections and wiring requirements.

Procedure for entering the controller's Set Up Mode using front panel keys.

Summary of parameters available for adjustment in Set Up Mode.

Configuration of the digital filter for the process variable input.

Adjusting the offset for the actual process variable value.

Setting Output Power and Proportional Band parameters.

Configuration of Reset, Rate, and Bias (Manual Reset) parameters.

Setting ON/OFF Differential and Setpoint High/Low Limits.

Defining the maximum and minimum values for the recorder output scale.

Setting Process High/Low Alarm, Band Alarm, and Deviation Alarm values.

Enabling Loop Alarm and setting Scale Range Decimal Point.

Enabling Manual Control, Auto Pre-Tune, and configuring communications.

Selecting Setpoint Strategy and setting the Lock Code.

Technique for determining PID parameters for controllers with Output 1.

Guidance on tuning PID parameters for controllers with Output 1 and Output 2.

Enhancing controller response using Self-Tune and Pre-Tune features.

Procedure for returning to Operator Mode from Set Up Mode.

Details on RS485 connections, enabling, and address selection.

Explains the ASCII protocol and the different message types (1-4).

How individual parameters are interrogated or modified via RS485.

Handling of error conditions and responses in RS485 communication.

Overview of MODBUS communication and supported functions.

Details on MODBUS message structures and CRC16 calculation.

Listing and explanation of parameter numbers for MODBUS communication.

Procedure for entering the controller's Configuration Mode.

Decoding the hardware definition code for controller configuration.

Detailed explanation of parameters configurable within Configuration Mode.

Steps for safely withdrawing the UDC 1000 Controller from its housing.

Procedures for removing and replacing Option PCBs.

Selecting input and output types using CPU PCB jumpers.

Instructions on how to use the product selection tables.

Detailed selection codes and ranges for inputs and outputs.

Selection codes for optional features like communication and power supply.

General specifications, thermocouple, RTD, and DC linear input details.

Specifications for outputs, loop control parameters, and alarms.

Details on communication protocols, layers, and performance conditions.

Operating conditions, EMI, dimensions, mounting, and weight.

Guide to selecting products for TPSC models of UDC 1000 controllers.

Wiring diagrams and relay output details for TPSC models.

Explanation of set up parameters for TPSC models.

| Display | Dual 4-digit LED |

|---|---|

| Mounting | Panel mount |

| Input Types | Thermocouple, RTD, mA, V |

| Output Types | Relay, SSR driver, 4-20 mA |

| Control Modes | On/Off, PID |

| Operating Temperature | 0 to 50°C |

| Accuracy | ±0.25% of span |