Do you have a question about the Honeywell UDC2800 and is the answer not in the manual?

Lists symbols and their definitions used in the document.

Lists related documents for further reference.

Lists key features of the UDC2800 controller.

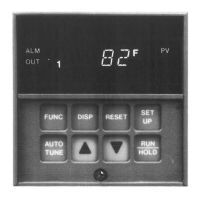

Details the controller's display elements and their functions.

Explains the capabilities and configuration of the two analog inputs.

Details the function of the two isolated digital inputs for remote control.

Lists the available output types for the UDC2800 controller.

Explains the alarm functionality, setpoints, and types.

Describes communication options like Modbus RTU and Ethernet TCP/IP.

Covers CE conformity and FCC information for North America.

Summarizes operating limits and specifications for installation.

Guide to understanding the controller's model number for selection.

Physical considerations and procedures for mounting the controller.

Electrical considerations, mains power, and circuit wiring for installation.

Identifies requirements and shows various wiring diagrams for controller connection.

Illustrates the hierarchy of setup and function prompts.

Configures lockout, password, and product restoration settings.

Establishes appropriate values for tuning constants.

Configures setpoint ramps, rates, and programs.

Manages automatic PID tuning for control loops.

Configures various algorithms and timer functions.

Selects and configures output types, digital status, and current output.

Configures parameters required for Input 1 and Input 2.

Manages controller process control including tuning, setpoints, and limits.

Configures controller communication via Bluetooth, Modbus, or Ethernet.

Configures alarm conditions, setpoints, and output selections.

Guides calibration for inputs, slidewire, current, and auxiliary outputs.

Worksheet to record controller configuration values.

Details the controller's display elements and key functions.

Procedures for entering security codes and managing lockout features.

Guides on viewing operating parameters and annunciators on the lower display.

Explains diagnostic messages and their meanings for troubleshooting.

Step-by-step guide for initial controller startup and configuration.

Defines and explains different control modes like Automatic and Manual.

Details how to configure and change local and remote setpoints.

Covers the autotuning method for self-regulating and integrating processes.

Minimizes process variable overshoot using fuzzy logic.

Explains how to use and switch between four sets of tuning constants.

Describes the Auto/Manual Station mode and its function.

Configures alarm conditions, setpoints, types, and states.

Explains the algorithm for controlling valves or actuators via two relays.

Procedures for configuring failsafe output values and modes.

Configuration for setpoint rates, ramps, and programs.

Describes field calibration procedures for Inputs 1 and 2.

Lists PV input range values for various sensor types.

Lists necessary equipment and wiring instructions for inputs.

Step-by-step guide for calibrating Input 1 or Input 2.

Procedure to restore factory calibration constants for input actuation types.

Calibrates the controller's output for proper current delivery over a range.

Calibrates the auxiliary output to provide proper current over a desired range.

Guides calibration for Position Proportional and Three Position Step outputs.

Restores factory calibration constants for Current and Auxiliary Outputs.

Introduces factors affecting performance and problem investigation order.

Provides guidance on handling error messages and failure symptoms.

Describes diagnostic tests performed at power-up and status checks.

Details ongoing background tests for data and memory integrity.

Lists numerical troubleshooting procedures for various failure symptoms.

Shows an exploded view of the UDC2800 Controller with labeled parts.

Lists part numbers by key number for the UDC2800 controller.

Introduces the EasySet app for instrument configuration via Bluetooth.

Procedure to set up mobile device communication parameters for EasySet app.

Steps to upload, edit, and download instrument configurations using the app.

Displays key operating and status parameters for diagnostics via the app.

Guide to updating UDC2800 device firmware using the EasySet IOS app.

Instructions for exporting configuration from legacy devices and importing to UDC2800.

Details the format of Modbus RTU messages for data transmission.

Explains Modbus RTU function codes for process data access.

Describes the structure of register addresses for parameter access.

Details function code 20 for reading configuration database items.

Details function code 21 for writing configuration database items.

Information on reading, writing, and overriding parameters via Modbus.

Explains how to use local setpoints and their register addresses.

Details the format of Modbus RTU messages for data transmission.

Explains the subset of Modbus RTU function codes used for process data access.

Maps register addresses for digital input and output parameters.

Maps register addresses for loop value parameters.

Maps register addresses for analog input parameters.

Maps registers for math, calculated value, or status parameters.

Maps register addresses for set point program values and segments.

Defines and describes Modbus RTU data layer status exception codes.

General overview of Ethernet TCP/IP configuration and network setup.

| Control Modes | PID, ON/OFF, Manual |

|---|---|

| Mounting | Panel Mount |

| Display | Dual 4-digit LED |

| Input Types | Thermocouple, RTD, mA, mV, V |

| Output Types | Relay |

| Power Supply | 100-240 VAC, 50/60 Hz |

| Communication | RS-485 Modbus RTU |

| Enclosure Rating | NEMA 4X |