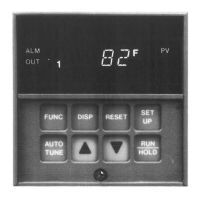

4 Monitoring and Operating the Controller Page: 193 4.1 Overview Provides a general overview of the controller's monitoring and operation.

4.4 Lockout Feature Describes the lockout feature to inhibit changes to functions or parameters by unauthorized personnel.

4.7 Control Modes Defines different control modes like Automatic, Manual, and Cascade.

4.8 Setpoints Explains how to configure and manage local and remote setpoints for the controller.

4.9 Timer Describes the timer function for configurable time-out periods and start selections.

4.10 Accutune III Covers the Accutune III autotuning method for self-regulating processes.

Totalizer Explains the Flow Totalizer function for calculating and displaying total flow volume.

Output Override Allows overriding Loop 1 output with Loop 2 output based on high/low selection.

4.21 Alarm Setpoints Details configuring alarm setpoints for relay contacts and operator interface indications.

Carbon Potential Details configuring the controller to measure and control Carbon Potential using input sensors.

Percent Oxygen Explains Percent Oxygen control using two analog inputs and controller calculations.

Dewpoint Describes Dewpoint Algorithm for controlling Dewpoint and calculating Carbon Potential.

4.26 Healthwatch Provides diagnostic data to monitor vital performance, predict failures, and minimize downtime.

4.28 Setpoint Rate Explains configuring a specific rate of change for any local setpoint change.

4.29 Setpoint Ramp Describes setting a ramp between current and final local setpoints over a time interval.

Loop Data Allows viewing the current status of each process loop via the Loop Data screen.

Status Data Allows viewing the current status of the controller's diagnostics.

Ethernet Status Displays the network status of the Ethernet Link, accessed via Ethernet or Infrared.

Healthwatch Data Shows the current values of counters and timers used by Healthwatch.

Totalizer Data Shows the current values of the Totalizer and allows resetting to zero.

Real Time Clock Shows controller and PC clock times and allows setting the controller's time.

10 Modbus Read, Write and Override Parameters plus Exception Codes Page: 347 10.1 Overview Introduces information on reading, writing, and overriding parameters and exception codes.

General Information Covers non-volatile memory retention, communications transfer rates, and modes of operation.

10.5 Setpoints Lists register addresses to select and enter setpoint values in Engineering Units or Percent.

10.7.1 Tuning Loop 1 Lists register addresses and ranges for function parameters in the Tuning Loop 1 Set-up Group.

10.7.2 Tuning Loop2 Lists register addresses and ranges for function parameters in the Tuning Loop 2 Set-up Group.

10.7.7 Accutune Lists register addresses and ranges for function parameters in the Adaptive Tune Set-up Group.

10.7.8 Algorithm Lists register addresses and ranges for function parameters in the Algorithm Set-up Group.

10.7.9 Math Lists register addresses and ranges for function parameters in the Math Set-up Group.

10.7.10 Logic Lists register addresses and ranges for function parameters in the Logic Set-up Group.

10.7.12 Input 1 Lists register addresses and ranges for function parameters in the Input 1 Set-up Group.

10.7.13 Input 2 Lists register addresses and ranges for function parameters in the Input 2 Set-up Group.

10.7.14 Input 3 Lists register addresses and ranges for function parameters in the Input 3 Set-up Group.

10.7.15 Input 4 Lists register addresses and ranges for function parameters in the Input 4 Set-up Group.

10.7.16 Input 5 Lists register addresses and ranges for function parameters in the Input 5 Set-up Group.

10.7.17 Control Lists register addresses and ranges for function parameters in the Control Set-up Group.

10.7.18 Control Loop 2 Lists register addresses and ranges for function parameters in the Control Loop 2 Set-up Group.

10.7.19 Options Lists register addresses and ranges for function parameters in the Options Set-up Group.

10.7.21 Alarms Lists register addresses and ranges for function parameters in the Alarms Set-up Group.

10.7.22 Maintenance Lists register addresses and ranges for function parameters in the Maintenance Set-up Group.

10.7.24 Display Lists register addresses and ranges for function parameters in the Display Set-up Group.

10.7.25 Clock Lists register addresses and ranges for function parameters in the Clock Set-up Group.