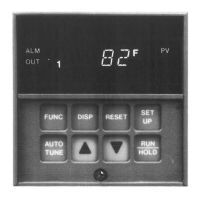

Monitoring and Operating the Controller

3/07 UDC3500 Universal Digital Controller Product Manual 241

should be configured to IN ALG 1 while PV Source in the Control 2 Set Up Group

should be configured to INPUT 2.

See Section 3.11 for configuration and other information.

Features

• Direct calculation of carbon percentage with seven different manufacturers’ probes:

• Advanced Atmosphere Control Corporation (AACC)

• Corning

• Cambridge Instruments

• Marathon Monitors

• Furnace Control Corporation

• MacDhui (Barber Colman)

• Bricesco

• ± 0.02 % accuracy

• No nomographs—no mistakes

• Probe temperature input type is selectable from complete input menu.

• Four different local setpoints—standard feature

• Duplex control with second set of PID constants for dilution air control

• Process factor adjustment capability

• Automatic sooting warning via flashing display and configurable alarm

• Carbon Potential Algorithms, PV Range: 0.0 to 2.0 % (0.1 to 1.4 % for specified

accuracy)

• Dewpoint Algorithm, PV Range: –50 °F to +100 °F (–45 °C to 38 °C)

• % Oxygen Algorithm, PV Range: 0 % to 40 %

• Second Control Loop can use the temperature input to control furnace temperature

Carbon Potential

The percent Carbon Monoxide (CO) content of the enriching gas may be entered as a

fixed value or Input 3 on the controller may be used to measure CO content as a live

value provided by a separate sensor.

All calculations are performed by the Controller with Percent Carbon shown as the PV

display. The actual reading of each analog input is available for viewing on the lower

display.

The controller computes the atmosphere’s actual carbon potential from these inputs and

compares the computed value with the desired setpoint. An on-off or PID control

algorithm determines the controller output necessary to keep the actual carbon potential

at the setpoint.

Loading...

Loading...